Polishing device with multi-angle driving structure

A drive structure, multi-angle technology, applied in the direction of grinding drive device, grinding machine, grinding/polishing equipment, etc., can solve the problems of poor adaptability and inflexibility, and achieve the effect of good grinding effect, flexible grinding and accurate measurement of data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

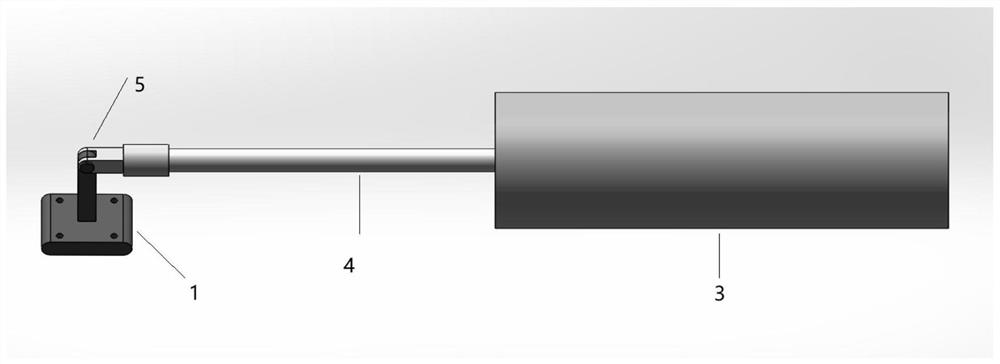

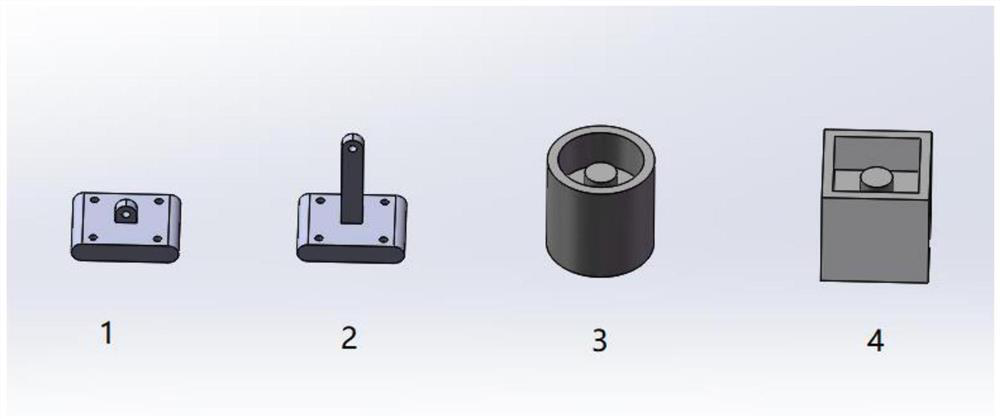

[0027] Such as figure 1 , figure 2 As shown, the grinding device with multi-angle driving structure disclosed in this embodiment includes a grinding head 1 , a dielectric EAP cylindrical driver 2 , a fixed casing 3 , a transmission rod 4 , a connector 5 , and a voltage controller 6 . When grinding, the voltage controller 6 is used to output a voltage of 5-10KV to make the grinding head carry out translational grinding.

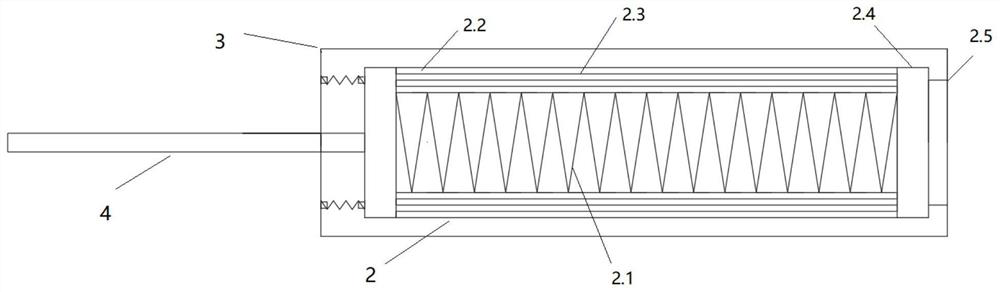

[0028] The EAP driver 2 includes a spring 2.1, a dielectric EAP film 2.2, a conductive paint 2.3, a fixed head 2.4, and a conductive wire 2.5.

[0029] The dielectric EAP cylindrical driver 2 is made by using the material of the dielectric EAP film 2.2, and the driver can generate axial deformation and axial driving force when electrified. Connect and fix the dielectric type EAP cylindrical driver 2 with the fixed shell 3 . By controlling the frequency and magnitude of the voltage output by the voltage controller 6, the output axial deformation and axial d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com