Device for realizing vacuum reflow soldering high-temperature uniformity and processing method thereof

A vacuum reflow, high temperature technology, used in electric heating devices, welding equipment, metal processing equipment, etc., to achieve high reliability, no voids in solder joints, and good high-frequency characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

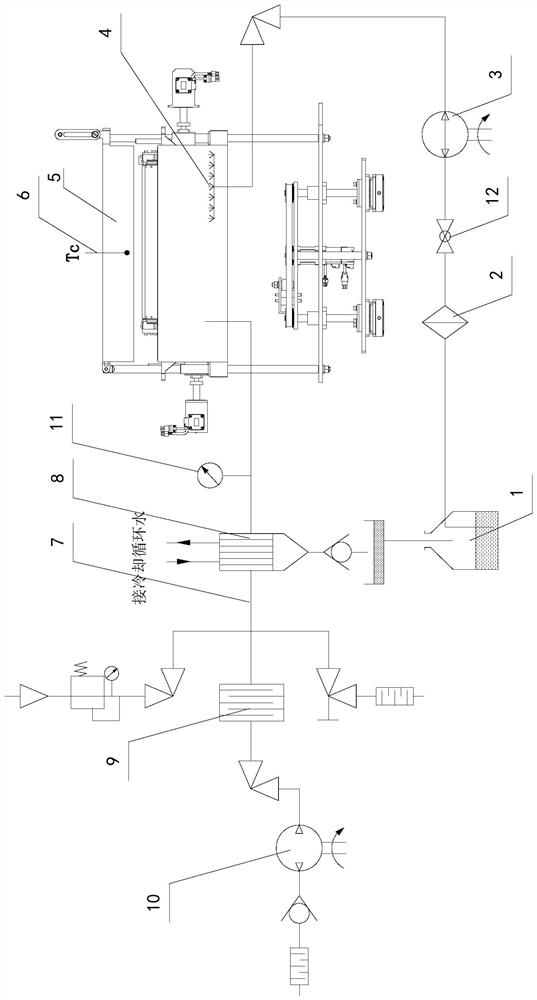

[0018] refer to figure 1 As shown, a device for achieving high temperature uniformity in vacuum reflow soldering is mainly composed of a vapor phase liquid storage tank 1, a first filter 2, a circulating pump 3, an injection valve 4, vacuum reflow soldering equipment, and a temperature control thermocouple 6, Vacuumizing pipeline 7, condensation filter 8, second filter 9, vacuum pump 10, vacuum gauge 11 and hand valve 12 are composed.

[0019] On the pipeline between the vapor phase liquid storage tank 1 and the vacuum reflow soldering equipment, a first filter 2, a hand valve 12, a circulation pump 3 are arranged in sequence, and a jet valve 4 is arranged in the vacuum cavity 5 of the vacuum reflow soldering equipment, After the vapor phase liquid in the vapor phase liquid storage tank 1 is filtered by the first filter 2 through the circulation pump 3, it is sprayed into the vacuum chamber 5 by the injection valve 4, and the vapor is made by the heating effect of the wall of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com