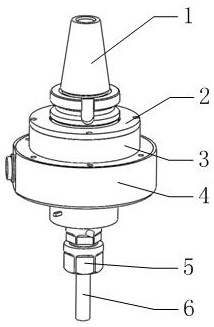

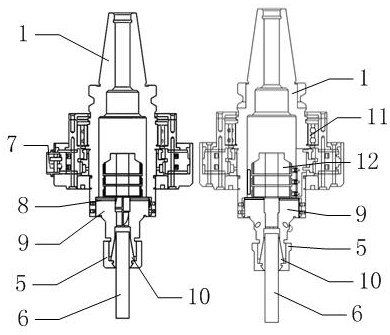

Ultrasonic milling device

A milling device and ultrasonic technology, applied in the field of milling, can solve problems such as bad conditions, increased volume, and weak rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

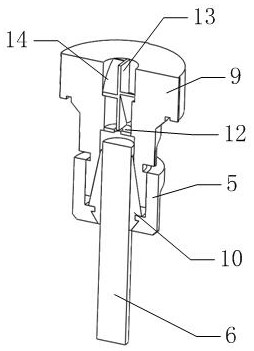

[0060] Embodiment: When using the device designed by the present invention, after the carbon brush rod 51 is worn for a long time, the pressure of the two third springs 48 on both sides will also change accordingly, so as to ensure that the carbon brush rod 51 on both sides is in contact with the positive pole. The ring 42 and the negative electrode ring 40 are in close contact, because the third spring 48 designed by the present invention tightens the carbon brush rod 51 from both sides, compared with the existing spring extruded at the rear side of the carbon brush rod 51, this The length of space that the third spring 48 can be arranged in the invention is far greater than the existing one, that is, the third spring 48 can have a longer pre-compression amount. The amount of pre-compression is very small, so when the change of the spring pre-pressure is relatively small after wear, the change of the extrusion force of the carbon brush rod 51 on the positive electrode ring 42 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com