Novel reactor and processing method thereof

A reactor, a new type of technology, applied in the field of reactors, can solve the problems of low mass transfer and heat transfer efficiency, uneven material mixing, etc., and achieve the effect of improving mixing efficiency, efficient mixing, and simple and efficient processing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: CFD calculation simulation reactor mixing efficiency

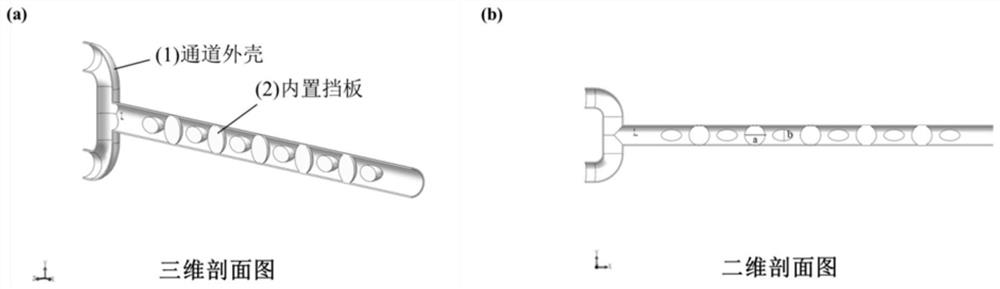

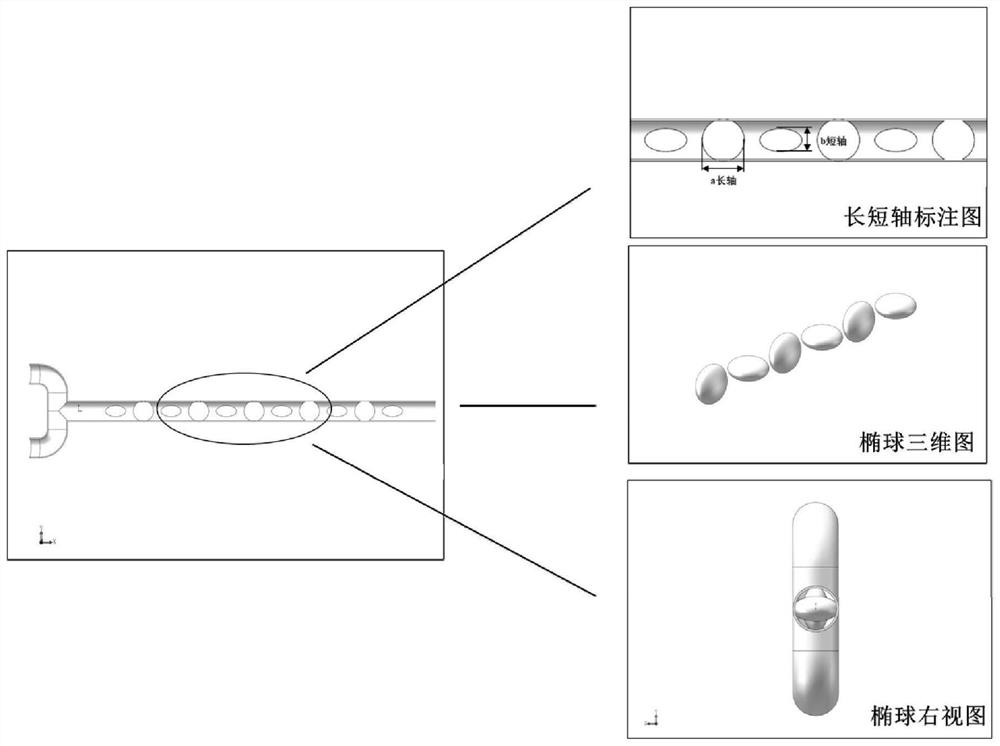

[0038] The outer diameter of the reactor shell 1 is 11mm, the inner diameter is 10mm, the long axis of the built-in ellipsoid baffle 2 is 11mm, the short axis is 6mm, the distance between the two ellipsoids is 15mm, the angle is 90°, the length of the mixing channel 200mm, such as figure 1 and figure 2 shown. Select liquid water with a density of 998.2kg / m 3 , the viscosity is 0.001003kg / m-s, and the velocity value is 0.01m / s. The laminar flow model is used to simulate the CFD calculation of the reactor, and the mixing efficiency, time to effect and length to effect are calculated at different lengths.

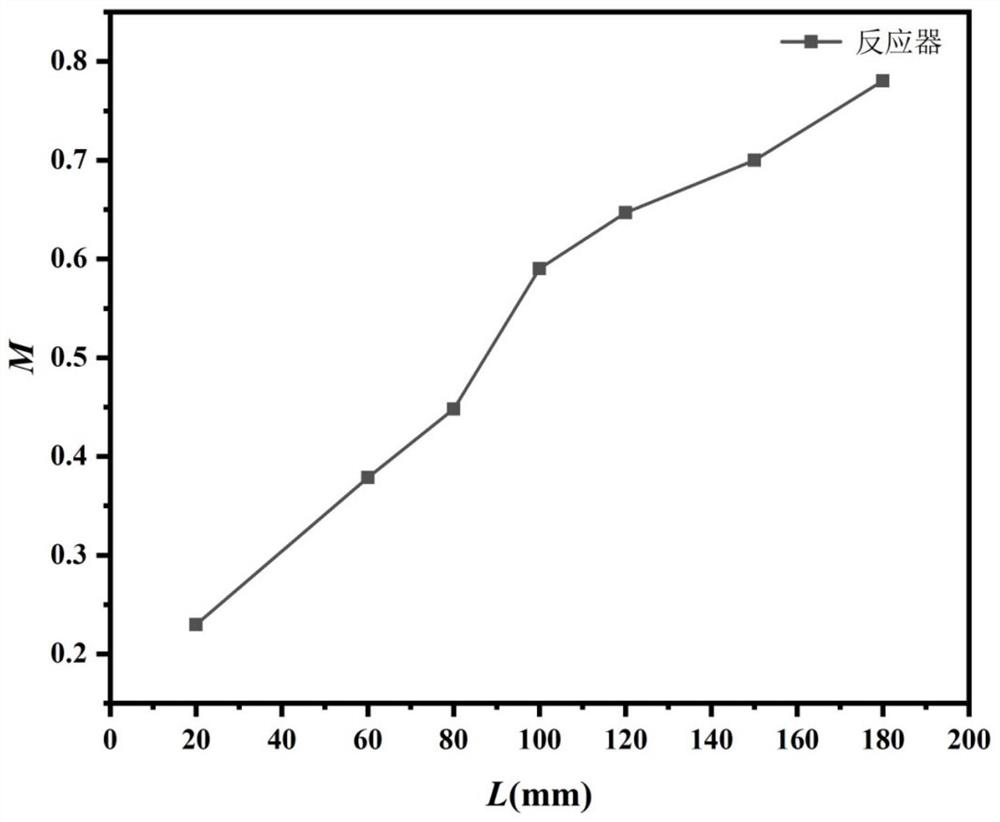

[0039] The results show that the effective length of the reactor structure is 180mm, and the effective time is 18s, such as image 3 shown. (Achieving effect length / time: the length and time required when the fluid mixing efficiency is 90%.

Embodiment 2

[0040] Example 2: CFD calculation and simulation of reactor mixing efficiency without built-in baffles

[0041] The outer diameter of the reactor is 11 mm, the inner diameter is 10 mm, and the length of the mixing channel is 500 mm. Select liquid water with a density of 998.2kg / m 3 , the viscosity is 0.001003kg / m-s, and the velocity value is 0.01m / s. Using the laminar flow model to carry out CFD calculation and simulation of the reactor, calculate the mixing efficiency at different lengths and perform linear fitting, such as Figure 4 shown.

[0042] The results show that the mixing effect of the reactor without built-in baffle structure increases linearly, and the fitting equation is: y=4.26278*10 -4 +0.16785; According to the linear fitting equation, it can be predicted that the effective length is 1717mm, and the effective time is 171.7s, and its mixing efficiency is obviously lower than that of the reactor with baffle plate structure.

Embodiment 3

[0043] Example 3: Reactor processing method - 3D printing by photocuring

[0044] First, use 3D modeling software to design the mold of the channel structure, and then import the STL file into the 3D printer modeling software, set the penetration depth of UV curing to 55 μm, and the curing time of each layer is 3 seconds, and the printing is completed after waiting for 350 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Inner diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com