Microbial preparation foam drainage gas production process

A microbial preparation and microbial technology, applied in the direction of mining fluid, earthwork drilling, wellbore/well parts, etc., can solve the problems of difficult foam elimination, increased production cost, complexity, etc., and achieve good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

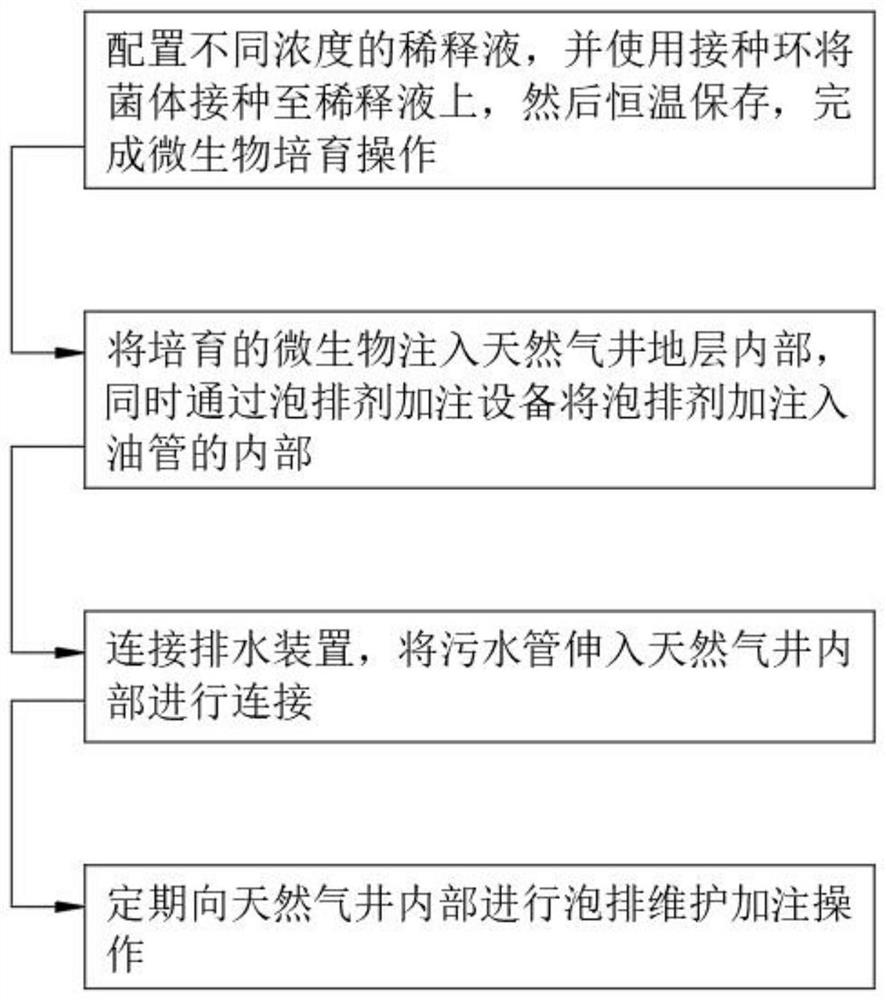

[0025] Such as figure 1 As shown, the present invention provides a kind of technical scheme: microbiological agent bubble row gas recovery process, comprises the following steps:

[0026] S1. Prepare diluents of different concentrations, and use an inoculation loop to inoculate the bacteria on the diluents, and then store them at a constant temperature to complete the microbial cultivation operation;

[0027] S2. Inject the cultivated microorganisms into the formation of the natural gas well, and inject the foaming agent into the oil pipe through the foaming agent filling equipment at the same time;

[0028] S3, connect the drainage device, extend the sewage pipe into the inside of the natural gas well for connection;

[0029] S4. Regularly carry out maintenance and filling operation of foam row to the inside of the natural gas well.

[0030] Wherein, the specific operation steps of microorganism cultivation in the step S1 are:

[0031] S11. Prepare diluent, take 1ml of nut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com