UHPC bridge deck pavement structure and preparation method thereof

A bridge deck paving and paving technology, used in bridges, bridge parts, bridge construction, etc., can solve the problems of limited fiber length and dosage, meet the requirements of crack resistance, avoid the binding of steel mesh, and improve the efficiency. The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

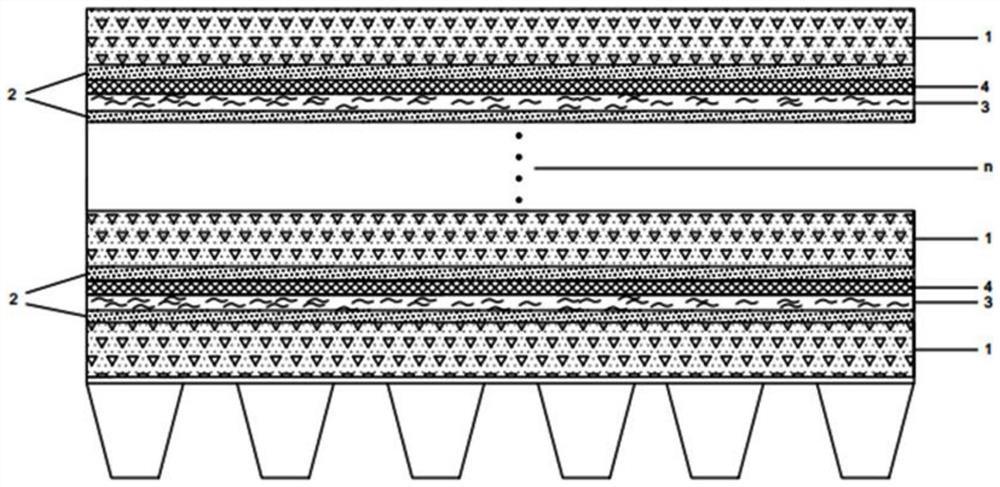

[0048] A UHPC bridge deck paving structure, the paving structure includes a plurality of paving units, and the paving units include a UHPC layer 1, an interlayer adhesive layer 2, a long fiber layer 3, a UHPC layer 1, an interlayer adhesive layer 2, a long fiber layer 3, The grid cloth layer 4, the interlayer adhesive layer 2, the paving unit is cycled many times, and finally the UHPC layer 1 is used to seal the layer.

[0049] The component content in each paving unit is as follows:

[0050] The materials of the UHPC layer include 2500 parts by mass of dry blend, 100 parts by mass of short fibers and 200 parts by mass of water; the total mass of the adhesive layer between the two layers is 80 parts by mass; the long fiber layer is 250 parts by mass; the mesh cloth layer 50 parts by mass.

[0051] The dry mix consists of 1200 parts by mass of premixed powder, 1200 parts by mass of aggregate, and 100 parts by mass of thixotropic regulator.

[0052] The premixed powder is comp...

Embodiment 2

[0073] A UHPC bridge deck paving structure, the paving structure includes a plurality of paving units, and the paving units include a UHPC layer 1, an interlayer adhesive layer 2, a long fiber layer 3, a UHPC layer 1, an interlayer adhesive layer 2, a long fiber layer 3, The grid cloth layer 4, the interlayer adhesive layer 2, the paving unit is cycled many times, and finally the UHPC layer 1 is used to seal the layer.

[0074] The component content in each paving unit is as follows:

[0075] The UHPC layer includes 1500 parts by mass of dry blend, 50 parts by mass of short fibers, and 90 parts by mass of water;

[0076] The long fiber layer includes 400 parts by mass of long fibers; the interlayer adhesive layer includes 150 parts by mass of the interlayer adhesive; and the mesh cloth layer includes 70 parts by mass of fiber mesh cloth.

[0077] The dry mix consists of 600 parts by mass of premixed powder, 800 parts by mass of aggregate, and 100 parts by mass of thixotropic ...

Embodiment 3

[0098] A kind of UHPC bridge deck pavement structure, described pavement structure comprises a plurality of pavement units, and described pavement unit comprises UHPC layer 1, interlayer adhesive layer 2, long fiber layer 3, Mesh cloth layer 4, interlayer adhesive layer 2, the pavement unit is cycled several times, and finally sealed with UHPC layer 1.

[0099] The component content in each pavement unit is as follows:

[0100] The UHPC layer includes 2800 parts by mass of dry blend, 180 parts by mass of short fibers, and 240 parts by mass of water; the long fiber layer includes 300 parts by mass of long fibers; the layer of interlayer binder includes 100 parts by mass of Bonding agent between; described mesh cloth layer comprises the fiber mesh cloth of 30 mass parts.

[0101] The dry mix consists of 1200 parts by mass of premixed powder, 1400 parts by mass of aggregate, and 200 parts by mass of a thixotropic regulator.

[0102] The premixed powder consists of 700 parts by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com