Production process of chrome-free tanning and vegetable-free tanning sofa leather

A production process, vegetable tanning technology, applied in leather degreasing, chemical treatment before tanning, small raw hide/large raw hide/leather/fur treatment, etc., can solve the problem of low purity of vegetable kneading, imperviousness to washing, serious pollution of chrome tanning of leather, etc. problem, to achieve the effect of solving the low content of vegetable tannin, avoiding metal chromium pollution, and short pile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

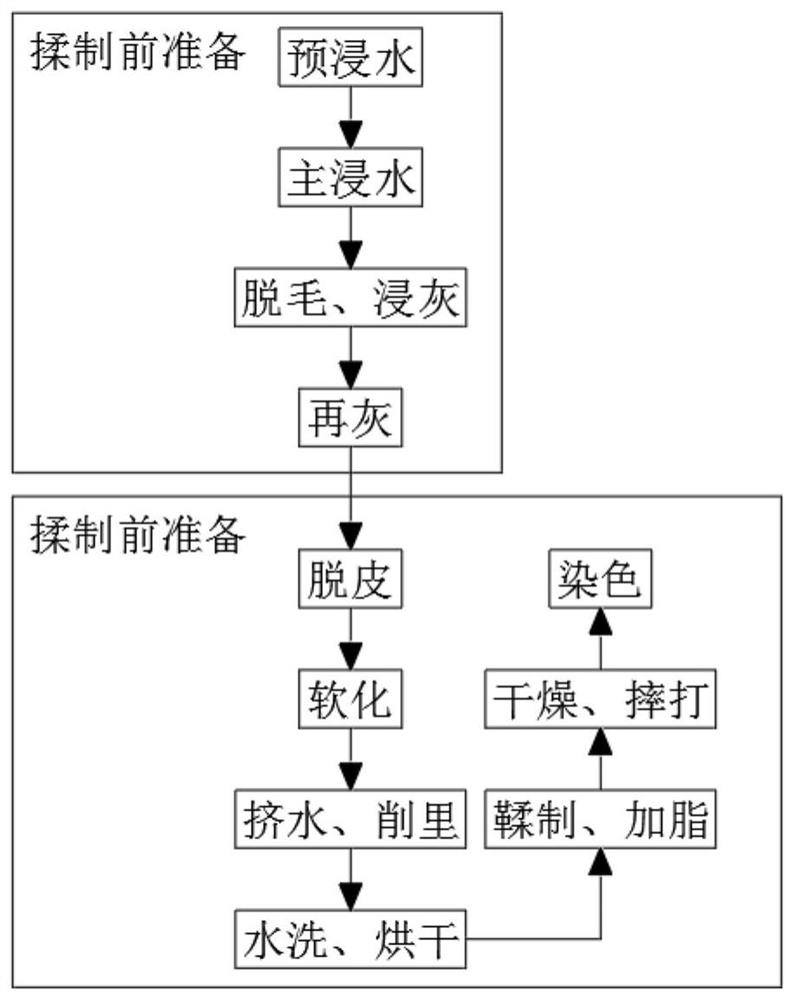

[0026] Such as figure 1 As shown, the embodiment of the present invention provides a kind of production technology of chrome-free tanning and non-vegetable tanning sofa leather, comprising following specific production process:

[0027] Step 1. First, pre-soak water to remove dirt and other sundries on the surface of the raw hide, and then realize main water immersion. During main water immersion, add back-humidity bactericide, enzyme water soaking agent and emulsifying degreasing agent;

[0028] Step 2. First add sodium hydrosulfide, liming aid and lime to the water, rub the surface of the raw hide to remove hair, then add sodium sulfide, lime and emulsified degreasing agent to make the lime penetrate evenly and the skin to expand moderately, making the surface of the raw hide Oil is emulsified and removed;

[0029] Step 3. Soften and pickle the raw hide. Add fermented agent and emulsifying degreasing agent to water to remove non-tissue collagen and waste collagen protein. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com