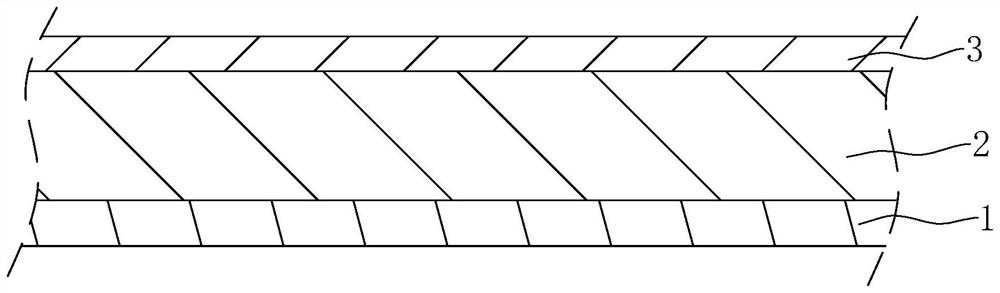

Sandwich structure self-adhesive damping foaming adhesive tape for vehicle, preparation method and damping structure

A sandwich and self-adhesive technology, applied in the direction of chemical instruments and methods, adhesives, rubber layered products, etc., can solve the problems that the cavity cannot be completely well sealed, the sound absorption and sound insulation performance cannot be provided, and the sound insulation and noise reduction effect is poor. Achieve good sustainable development prospects, long service life, and improve the effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

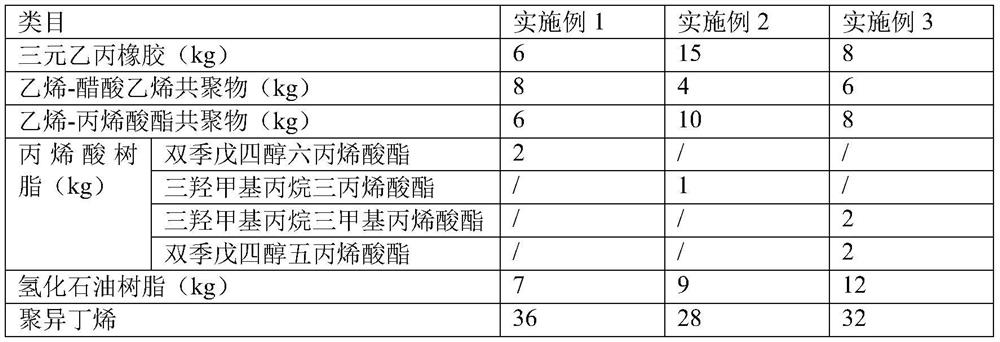

Embodiment 1

[0060] The embodiment of the present application discloses a self-adhesive damping foam strip with a sandwich sandwich structure for vehicles, including the following raw materials: 6kg EPDM rubber, 8kg ethylene-vinyl acetate copolymer, 6kg ethylene-acrylate copolymer, 2kg acrylic acid Resin, 7kg hydrogenated petroleum resin, 36kg polyisobutylene, 30kg mica powder, 4.9kg organic foaming agent, 0.1kg crosslinking agent.

[0061] The acrylic resin is dipentaerythritol hexaacrylate.

[0062] The mica powder is hydromica with a mesh number of 800 mesh.

[0063] The organic foaming agent is AC foaming agent, and the crosslinking agent is initiator DTBP.

[0064] The embodiment of the present application also discloses a method for preparing a self-adhesive damping foam strip with a sandwich sandwich structure for vehicles, including the following steps:

[0065] Step 1): Pre-dry the hydromica in an oven to remove moisture and set aside. The staff can adjust the baking time accor...

Embodiment 2-3

[0071] A sandwich sandwich structure self-adhesive damping foam rubber strip for vehicles, which differs from Example 1 in that:

[0072] The dosages of EPDM rubber, ethylene-vinyl acetate copolymer, ethylene-acrylate copolymer, hydrogenated petroleum resin, and polyisobutylene are different.

[0073] The specific selection and dosage of acrylic resin, mica powder, organic foaming agent and crosslinking agent are different. See Table 2 for details, and the data of Example 1 are also summarized in Table 2.

[0074] Table 2

[0075]

[0076]

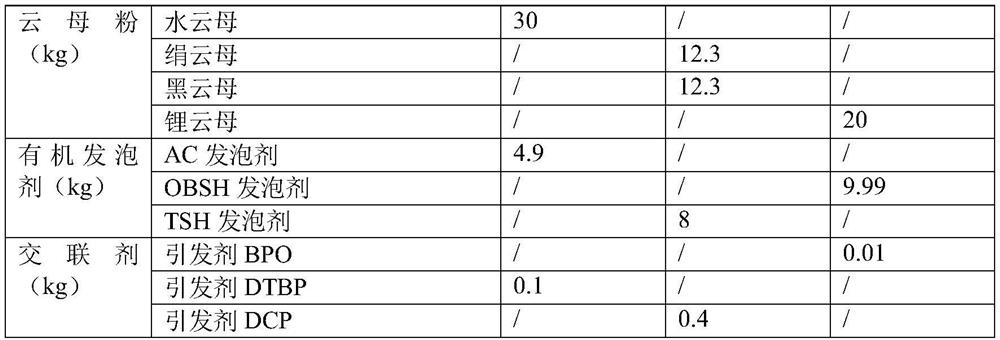

Embodiment 4

[0078] A sandwich sandwich structure self-adhesive damping foam strip for vehicles, the difference from Example 3 is that the mass ratio of acrylic resin, organic foaming agent and mica powder is 2.5:6.5:27, and the acrylic resin is double Pentaerythritol pentaacrylate, the organic foaming agent is OBSH foaming agent, and the mica powder is a mixture of hydromica and biotite. The dosage of each raw material is shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com