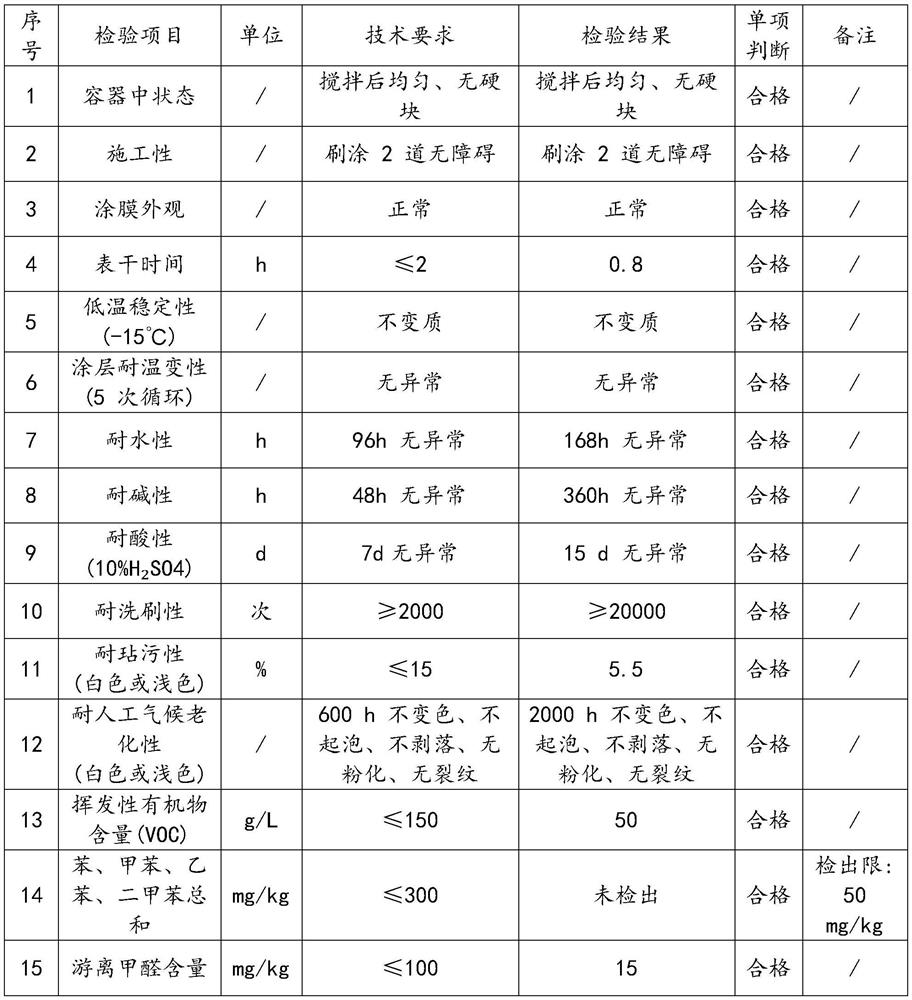

Exterior wall latex paint with both surface drying time and weather resistance and preparation method of exterior wall latex paint

A surface-drying time, latex paint technology, applied to latex paints, biocide-containing paints, coatings, etc., can solve the problems of reducing the surface drying time of latex paints, poor air permeability of paints, bubbling, etc., and achieve loess cost Low cost, strong weather resistance, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] An exterior wall latex paint that takes both surface drying time and weather resistance into account. The latex paint is composed of the following raw materials in parts by weight: 310 parts of water, 200 parts of modified loess powder, 170 parts of heavy calcium carbonate, 38 parts of kaolin, and 996 parts of titanium 30 parts of white powder, 5.0 parts of HHBR cellulose, 15 parts of lauryl alcohol ester, 2.0 parts of AMP-95 multifunctional additive, 4.0 parts of 5040 dispersant, 6.5 parts of 5027 dispersant, 2.6 parts of DP-18 wetting agent, 1340 disinfectant 1.8 parts of foaming agent, 2.0 parts of NXE defoamer, 14.5 parts of ethylene glycol, 1.6 parts of MB-11 fungicide, 17 parts of FD1000 fluorocarbon emulsion and 180 parts of 615D emulsion.

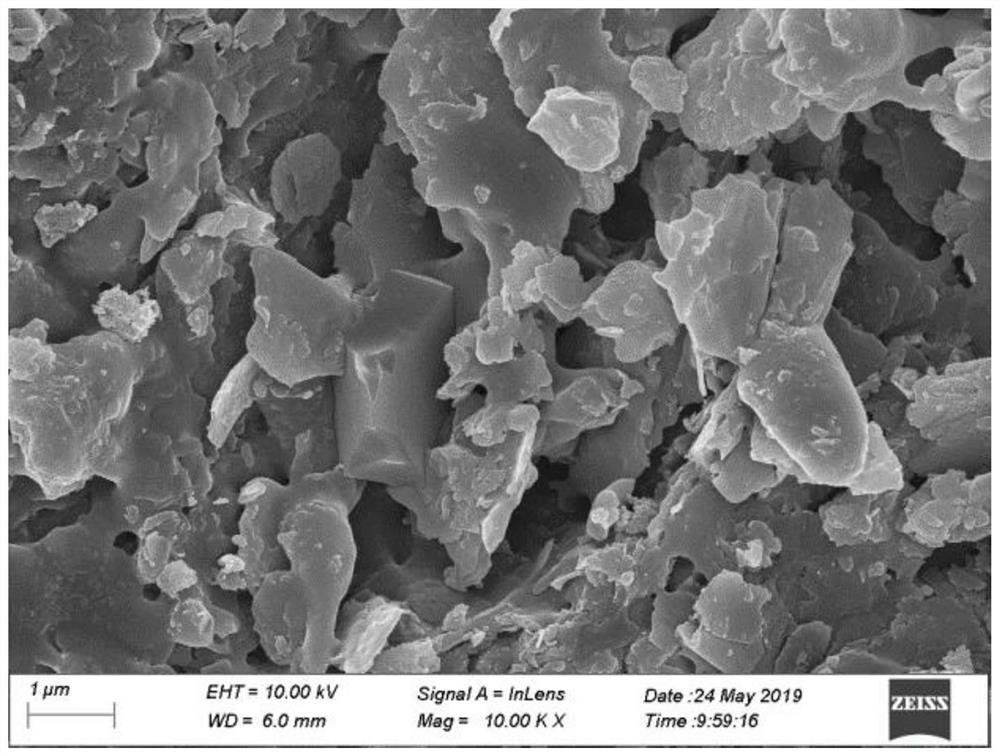

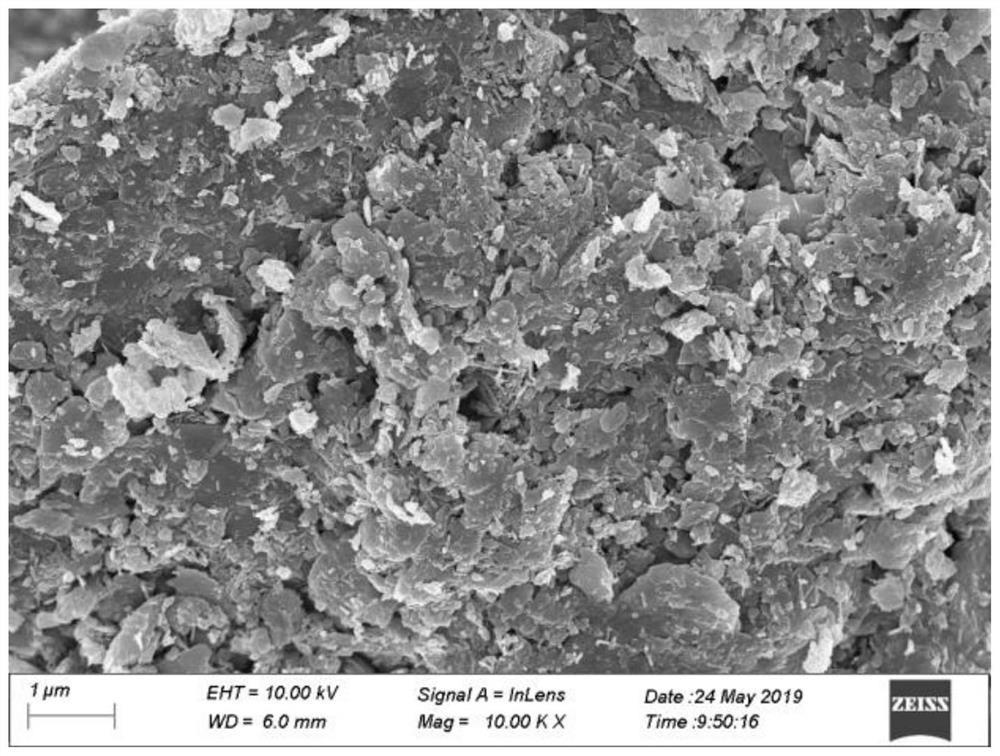

[0046] Among them: modified loess powder refers to adding clean and dry loess to pure water with a mass of 2.5 to 3.5 times, stirring evenly and settling naturally, removing the upper suspension and bottom fine sand impurities...

Embodiment 2

[0054] An exterior wall latex paint that takes both surface drying time and weather resistance into account. The latex paint is composed of the following raw materials in parts by weight: 320 parts of water, 230 parts of modified loess powder, 130 parts of heavy calcium carbonate, 50 parts of kaolin, and 996 parts of titanium 20 parts of white powder, 4.8 parts of HHBR cellulose, 17 parts of lauryl alcohol ester, 1.8 parts of AMP-95 multifunctional additive, 5.0 parts of 5040 dispersant, 7.0 parts of 5027 dispersant, 2.0 parts of DP-18 wetting agent, 1340 disinfectant 2.2 parts of foaming agent, 2.5 parts of NXE defoamer, 14.2 parts of ethylene glycol, 1.5 parts of MB-11 fungicide, 22 parts of FD1000 fluorocarbon emulsion and 170 parts of 615D emulsion.

[0055] Wherein: the preparation method of modified loess powder and latex paint is with embodiment 1.

Embodiment 3

[0057] An exterior wall latex paint that takes both surface drying time and weather resistance into account. The latex paint is composed of the following raw materials in parts by weight: 300 parts of water, 240 parts of modified loess powder, 150 parts of heavy calcium carbonate, 20 parts of kaolin, and 996 parts of titanium 40 parts of white powder, 4.5 parts of HHBR cellulose, 16 parts of lauryl alcohol ester, 1.6 parts of AMP-95 multifunctional additive, 3.9 parts of 5040 dispersant, 6.0 parts of 5027 dispersant, 2.5 parts of DP-18 wetting agent, 1340 disinfectant 2.0 parts of foaming agent, 2.8 parts of NXE defoamer, 14.0 parts of ethylene glycol, 1.7 parts of MB-11 fungicide, 20 parts of FD1000 fluorocarbon emulsion and 175 parts of 615D emulsion.

[0058] Wherein: the preparation method of modified loess powder and latex paint is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com