Preparation method of ionic gel stretchable electroluminescent device based on imidazole chloride salt

An electroluminescent device, ion gel technology, applied in the direction of electric solid device, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of poor mechanical stability and insufficient electrical conductivity of light-emitting devices, and achieve low cost and electrical conductivity. Excellent and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

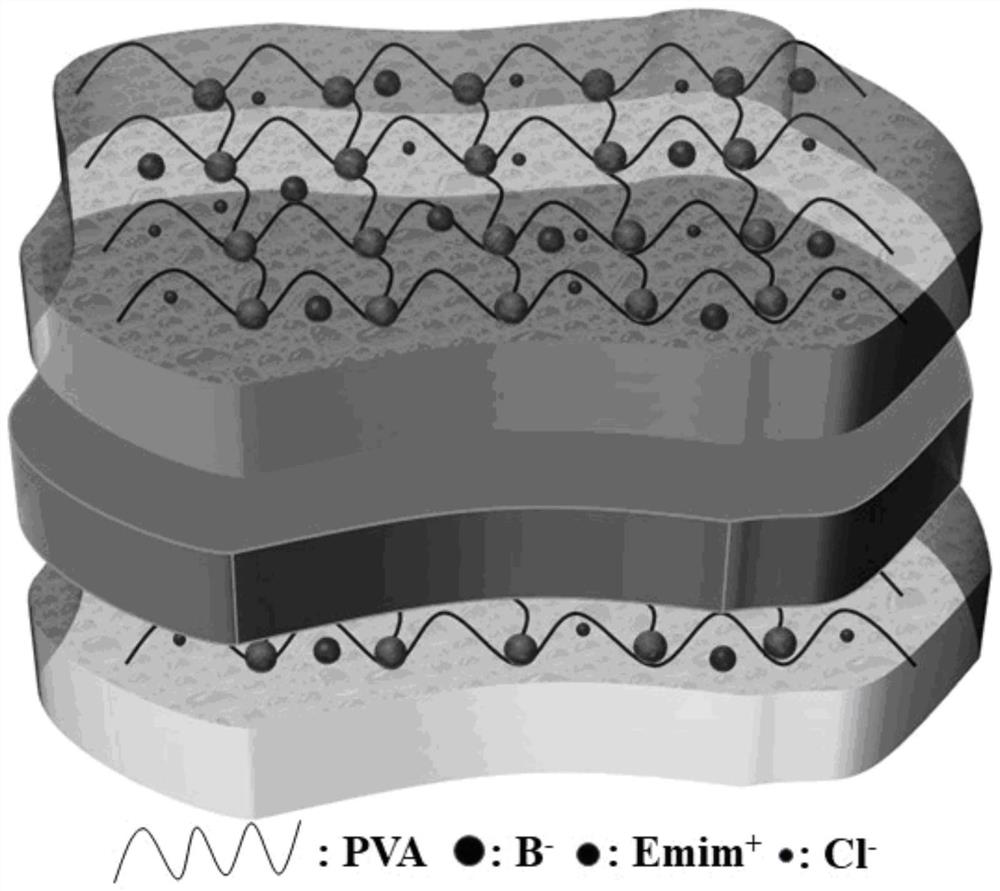

[0031] Preparation of ion gels. Dissolve PVA, BA, and EmimCl in distilled water (0.125g / mL, 0.0063g / mL, and 0.05g / mL, respectively), mix and stir the materials, and then ultrasonicate for 30 minutes to remove air bubbles. The reaction was stirred at 90° C. for 1 h, cooled to room temperature, and the ion gel was prepared.

[0032] Take 1g doped Cu 2+ 5g of PDMS was added to ZnS fluorescent powder (doping ratio: 0.01wt%), stirred evenly to form an emulsion, and ultrasonic treatment was performed for 30 minutes to remove air bubbles. Put the emulsion into an oven at 80°C to react for 3 hours, and solidify to obtain the electroluminescent layer

[0033] Use a wire bar coater to use the obtained electroluminescent layer as a substrate, and use the roller coating method to coat the ion gel prepared above on both ends of the substrate respectively, and put the coated device into a refrigerator at -4 °C After 12 hours of reaction, it was taken out and cooled to room temperature. ...

Embodiment 2

[0037] Preparation of ion gels. Dissolve PVA, BA, and EmimCl in distilled water (0.125g / mL, 0.0063g / mL, and 0.05g / mL, respectively), mix and stir the materials, and then ultrasonicate for 30 minutes to remove air bubbles. The reaction was stirred at 80° C. for 1 h, cooled to room temperature, and the ion gel was prepared.

[0038] Take 2g doped Cu 2+ 5g PDMS was added to the ZnS fluorescent powder (doping ratio 0.03wt%), stirred evenly to form an emulsion, and ultrasonic treatment was performed for 30 minutes to remove air bubbles. Put the emulsion into an oven at 80°C to react for 3 hours, and solidify to obtain the electroluminescent layer

[0039] Use a wire bar coater to use the obtained electroluminescent layer as a substrate, and use the roller coating method to coat the ion gel prepared above on both ends of the substrate respectively, and put the coated device into a refrigerator at -4 °C After 12 hours of reaction, it was taken out and cooled to room temperature. ...

Embodiment 3

[0042] Preparation of ion gels. Dissolve PVA, BA, and EmimCl in distilled water (0.15 g / mL, 0.001 g / mL, and 0.08 g / mL, respectively), mix and stir the materials, and then ultrasonicate for 30 min to remove air bubbles. The reaction was stirred at 90° C. for 1 h, cooled to room temperature, and the ion gel was prepared.

[0043] Take 1g doped Cu 2+ 5g PDMS was added to the ZnS fluorescent powder (doping ratio 0.05wt%), stirred evenly to form an emulsion, and ultrasonic treatment was performed for 30 minutes to remove air bubbles. Put the emulsion into an oven at 80° C. to react for 3 hours, and solidify to obtain an electroluminescent layer.

[0044] Use a wire bar coater to use the obtained electroluminescent layer as a substrate, and use the roller coating method to coat the ion gel prepared above on both ends of the substrate, and put the coated device into a refrigerator at -4 °C After 18 hours of reaction, it was taken out and cooled to room temperature.

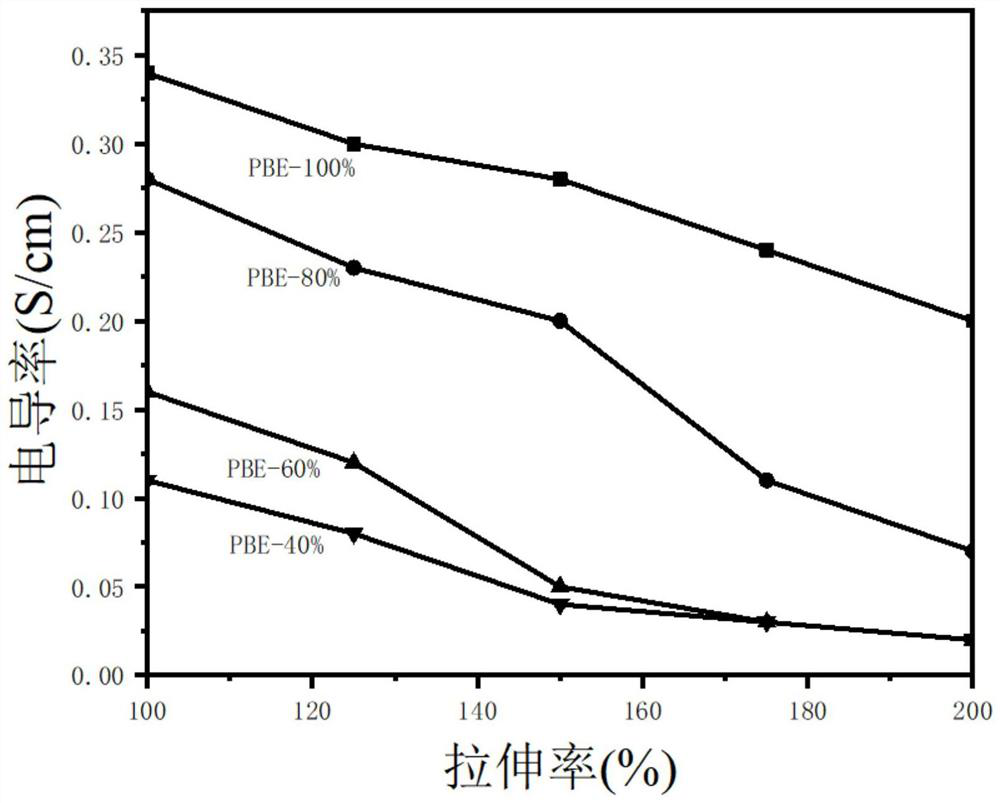

[0045] Fig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com