Light source module

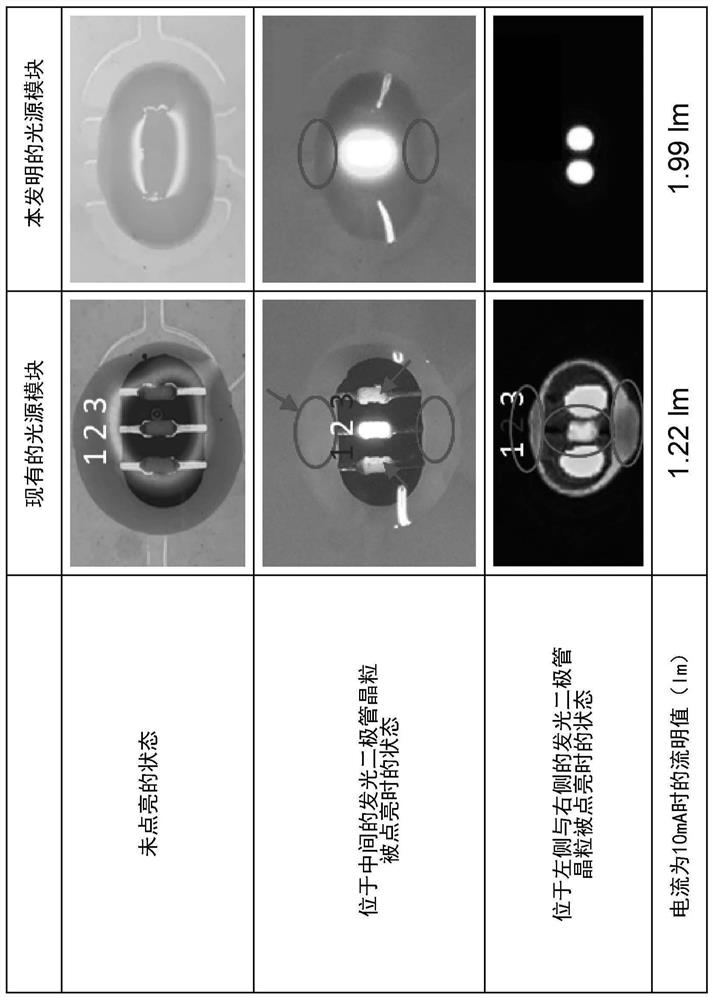

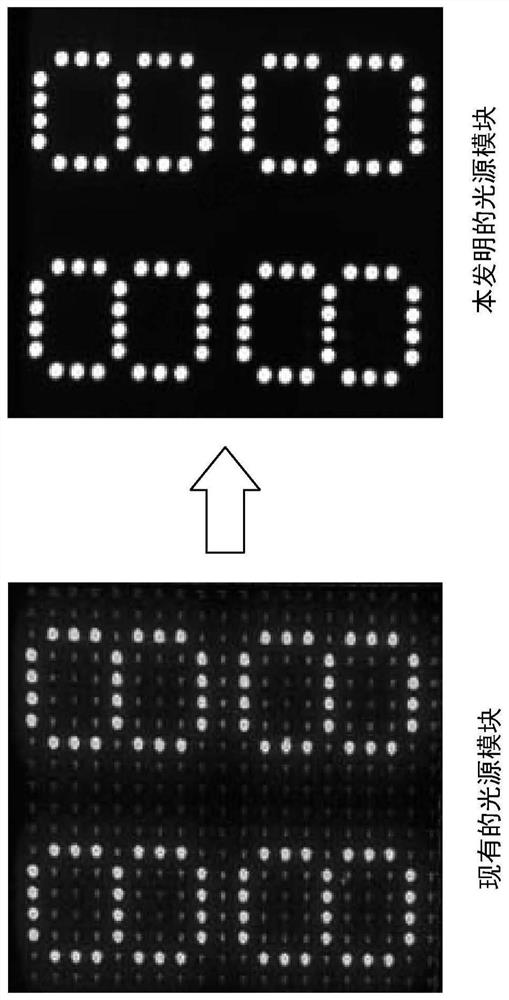

A light source module and light-emitting element technology, which is applied in the direction of electrical components, electric solid devices, circuits, etc., can solve problems such as halos, and achieve the effects of improving brightness, reducing assembly labor costs, and reducing overall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] see figure 1 , which is a schematic cross-sectional view of a light source module according to an embodiment of the present invention. Such as figure 1 As shown, the light source module 1 of this embodiment includes a substrate 10 , a plurality of light emitting elements 11 disposed on the substrate 10 , and an encapsulant 12 . In this embodiment, the substrate 10 is, for example, a circuit board, and the light-emitting elements 11 are, for example, light-emitting diode chips, but the present invention is not limited thereto. Each light-emitting diode chip is electrically connected to the circuit board, so it can be Receives current from the circuit board and outputs light. The encapsulating adhesive material 12 is formed on the substrate 10, and the encapsulating adhesive material 12 covers the two light emitting elements 11. In this embodiment, the encapsulating adhesive material 12 includes a polymer adhesive material, a white powder material and a black powder mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com