White-layer-free nitriding method for gear ring in wind power speed increasing box

A technology for speed-up gearboxes and internal gears, which is applied in coatings, solid-state diffusion coatings, and non-electric variable control. It can solve problems such as over-thickness, achieve wide adjustment ranges, fast adjustment speeds, and prevent interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

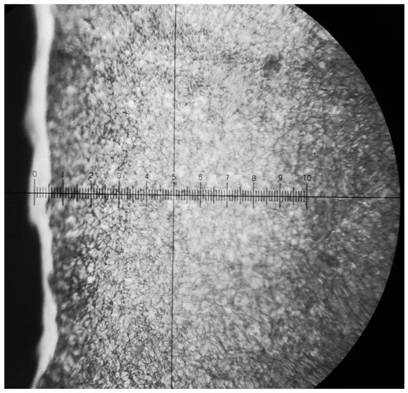

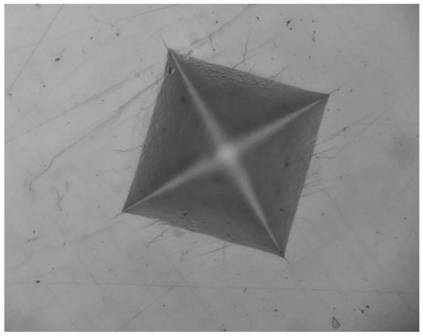

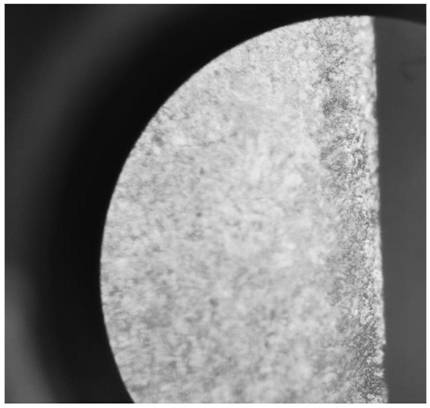

Image

Examples

Embodiment 1

[0020] A method for nitriding the inner ring gear of a wind power speed-up gearbox without a white layer, comprising the following steps:

[0021] The austenitizing heating temperature is 910°C, and 0.4% carbon potential is used to protect the inner ring gear workpiece of the wind power gearbox during heating, and the tempering temperature is 610°C to obtain the required quenching and tempering hardness and structure.

[0022] Raise the temperature of the nitriding furnace and feed N 2 Make a replacement.

[0023] When the furnace temperature rises to 450°C, turn off the N 2 at the same time and pass into NH 3 Make a replacement.

[0024] When the furnace temperature rises to 510°C, feed NH3 and crack NH at the same time 3 And automatically control the ammonia decomposition rate to 50% for strong infiltration, and keep it warm for 25 hours.

[0025] When the furnace temperature rises to 520°C, NH 3 and split NH 3 And automatically control the ammonia decomposition rate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com