Preparation process of thermal insulation type expanded perlite composite material for building

A technology of expanded perlite and composite materials, applied in the field of building materials, can solve the problems of difficult mixing, poor molding quality, and high density of expanded perlite, and achieve the effect of uniform adsorption and improved molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

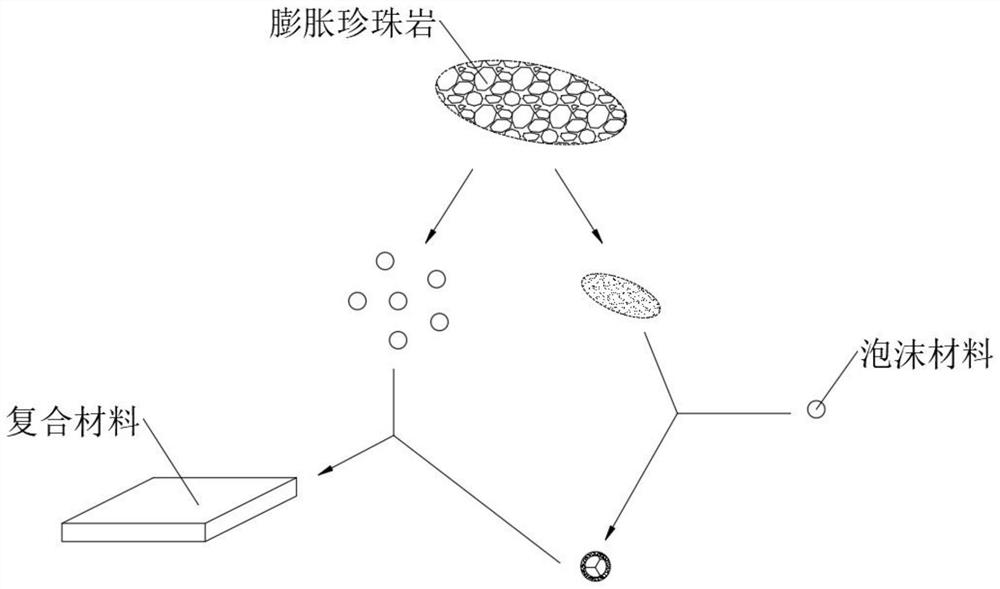

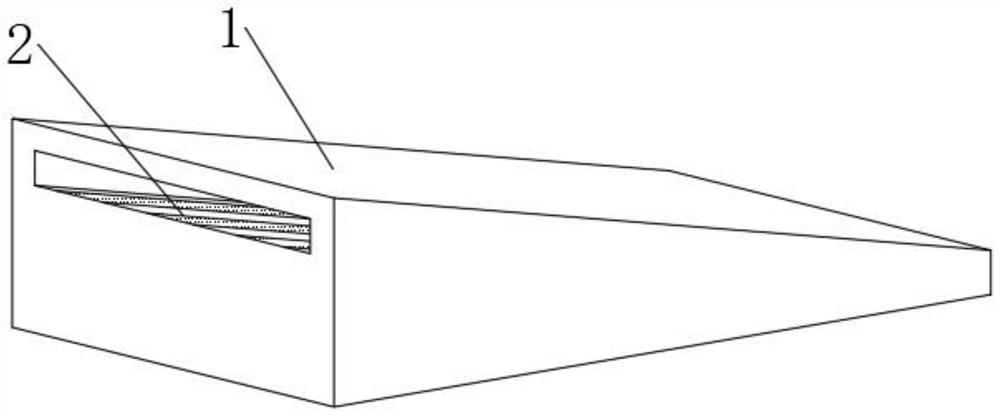

[0048] see figure 1 , a kind of heat preservation type expanded perlite composite material preparation process for building, comprises the following steps:

[0049] S1. Take the foam material and immerse it into the adhesive, and then filter it out to form an adhesive film layer on the surface;

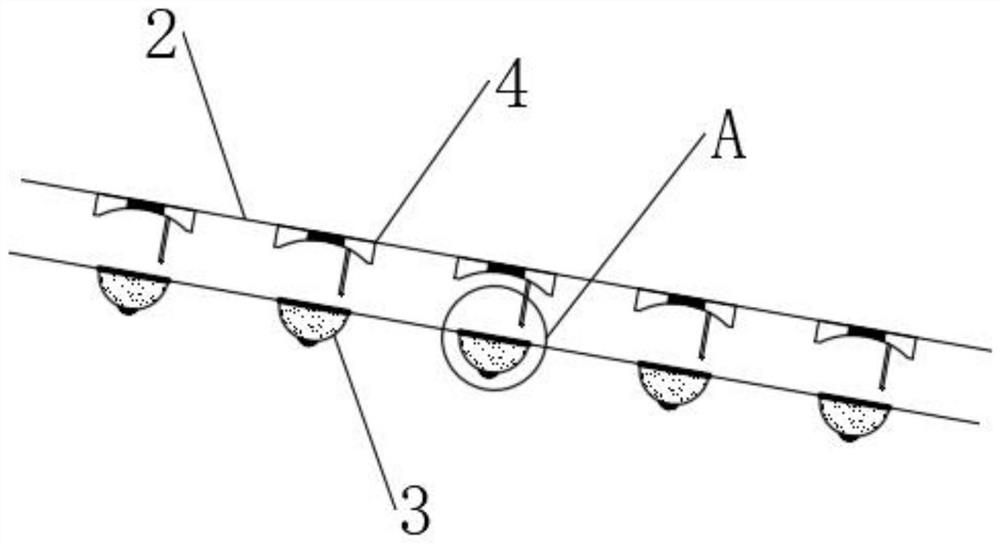

[0050] S2. Grinding the expanded perlite twice and screening out the raw materials with large particle size and small particle size, mixing the small particle size raw materials with mortar powder and then filling them into the counterweight belt;

[0051] S3. The foam material is rolled down along the counterweight belt, and the adhesive film layer is used to absorb the small particle size raw material and the mortar powder to combine and increase the weight, and then heat up and solidify to obtain a composite material;

[0052] S4. After fully mixing the composite material and the raw material with a large particle size, add the remaining adhesive to fully mix and infiltrate;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com