Railway tank car body and railway tank car

A technology of tank body and tank car, applied in the field of railway tank car body and railway tank car, can solve the problems of insufficient strength of the tank body, pollution of the environment, medium steam escape, etc. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

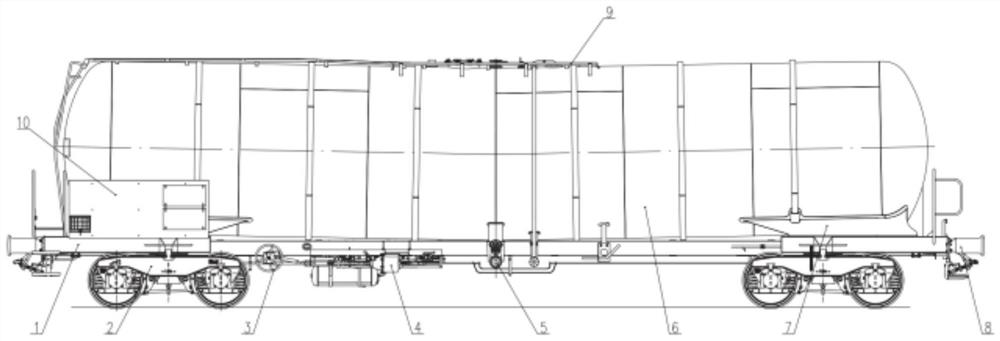

[0037] This embodiment provides a railway tank car body, such as figure 1 As shown, it includes a tank assembly 6, a chassis assembly 1, a loading and unloading system 5, and a tank bracket assembly 7. The tank assembly 6 is installed on the chassis assembly 1 through the tank bracket assembly 7, and the loading and unloading system 5 Installed on tank body assembly 6.

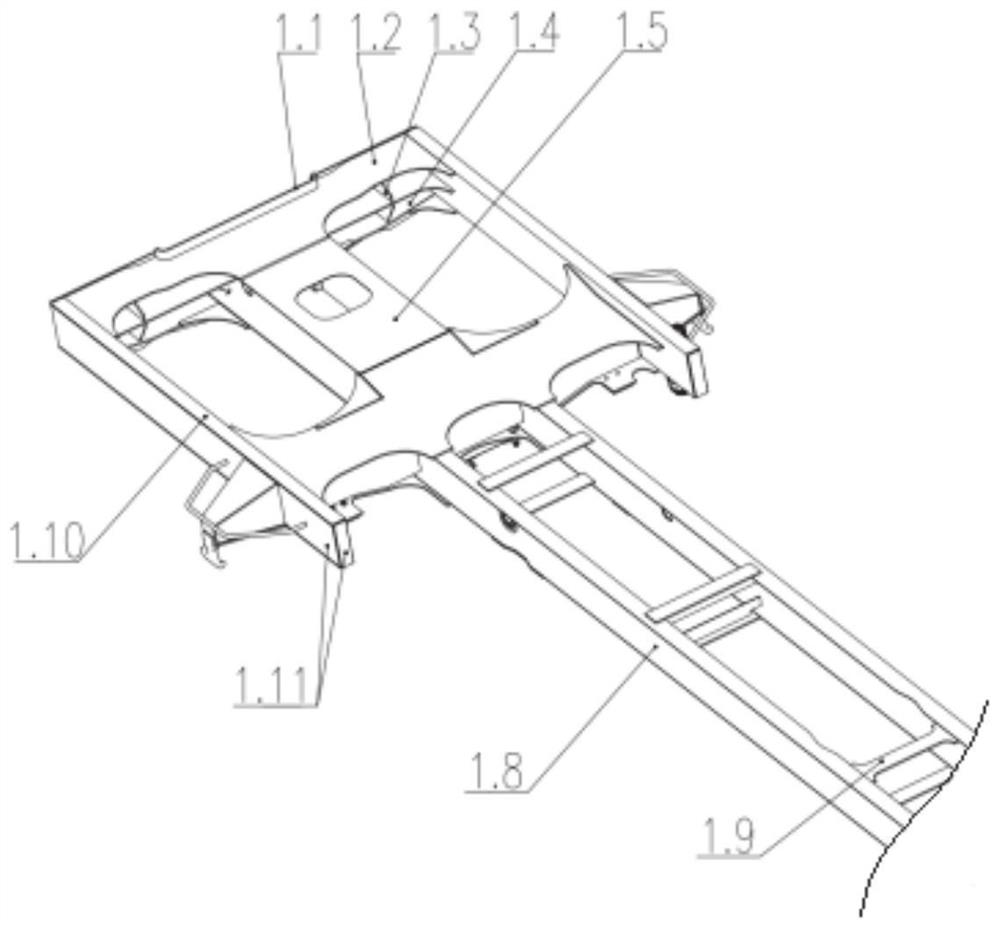

[0038] In order to meet the lightweight requirements of the car body and meet the strength requirements under normal working conditions, the underframe assembly 1 of this embodiment adopts the structural form of "stretch pillow + center beam", and the two ends of the center beam are respectively connected to the traction pillow. like figure 2 As shown, the traction pillow includes an end beam, a traction beam 1.5, a corbel and a side beam 1.10, and the traction beam 1.5 is a hollow structure, one end of which is connected to the end beam, and the other end is connected to the corbel to form an I-shaped struc...

Embodiment 2

[0070] This embodiment provides a kind of railway tank car, such as figure 1 As shown, it includes the railway tank car body described in Embodiment 1, and also includes a bogie 2, a parking brake device 3, and an air brake device 4. Both ends of the chassis assembly 1 are equipped with bogies 2, and the parking The vehicle brake device 3 and the air brake device 4 are respectively installed on the bottom of the chassis assembly 1 through the hanger, and are located below the first cylinder 6.2 or the second cylinder 6.3.

[0071] The coupler buffer device 8 is installed on the outside of the end beam of the underframe assembly 1 through bolts; The transverse central plane of frame composition 1 overlaps, and suitable space is reserved for the two ends of chassis assembly 1, walks the platform with the end of welding platform assembly 9, makes full use of the longitudinal space of chassis assembly 1.

[0072]The outer side of one end of the tank body assembly 6 and the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com