Cold-rolled silicon steel thickness control method and device based on full-process data

A technology of cold-rolled silicon steel and thickness control, applied in rolling mill control device, rolling force/roll gap control, metal rolling, etc., to avoid defects and ensure thickness accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

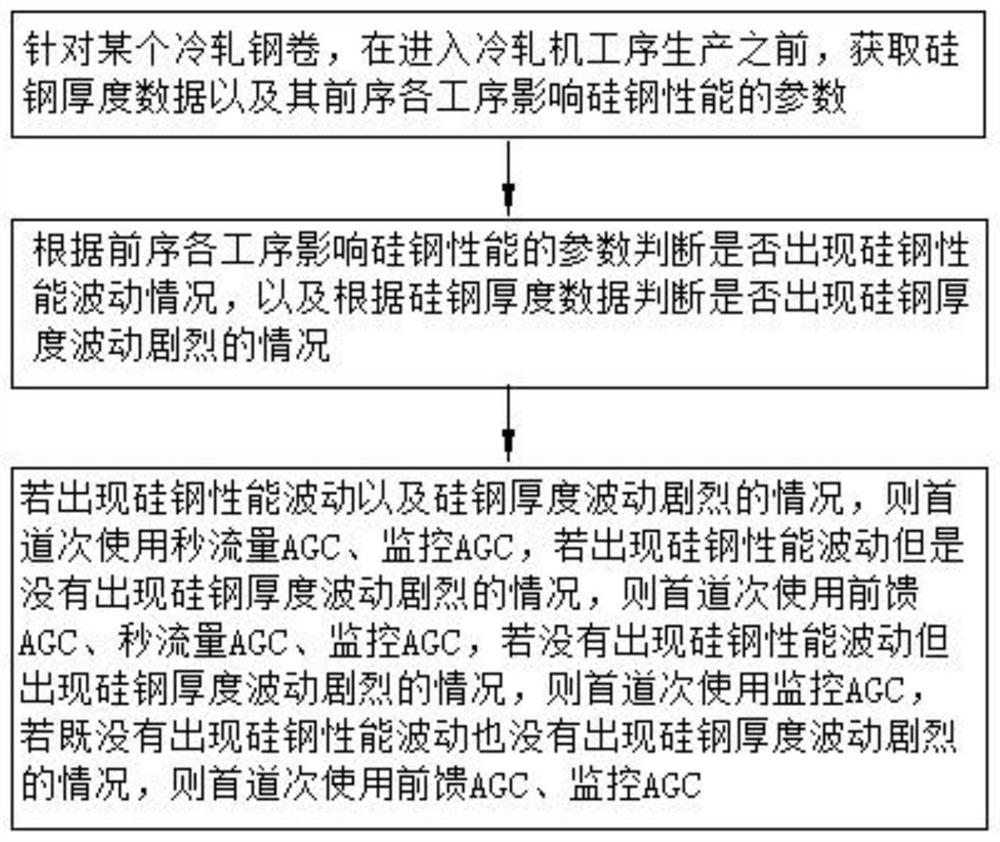

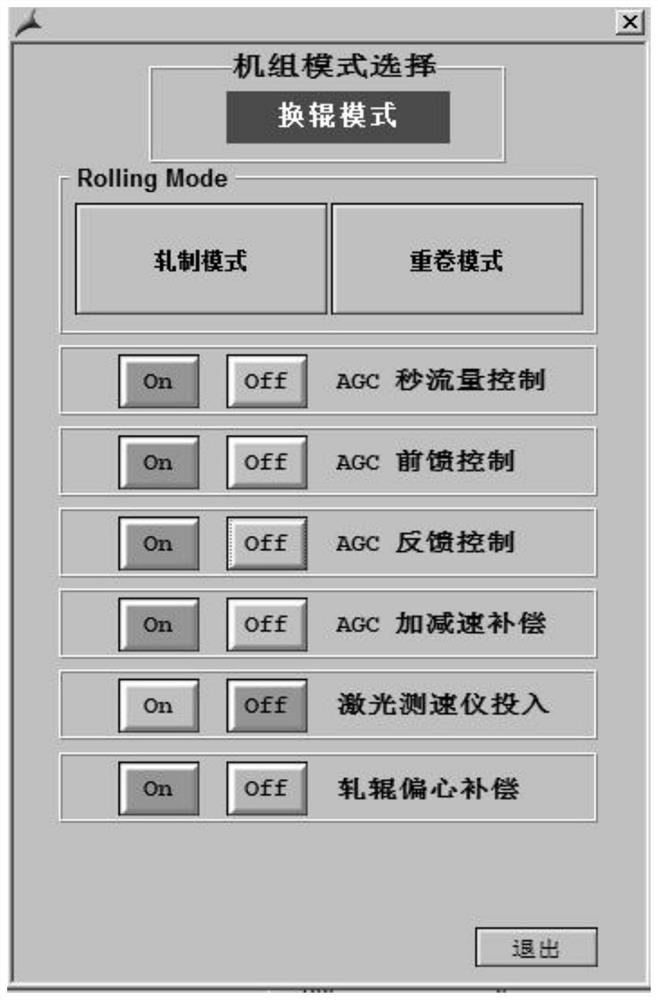

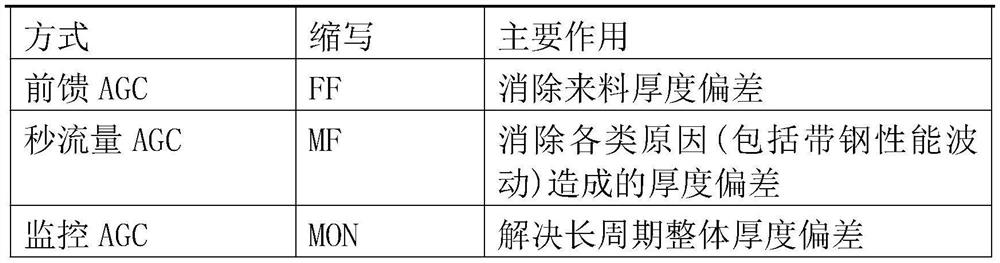

[0049] see figure 1 , the embodiment of the present invention discloses a method for controlling the thickness of cold-rolled silicon steel based on the whole process data, including the following steps: for a certain cold-rolled steel coil, before entering the production process of the cold-rolling mill, obtaining the thickness data of silicon steel and its preamble The parameters affecting the performance of silicon steel in each process, judge whether there is a fluctuation in the performance of silicon steel according to the parameters affecting the performance of silicon steel in each process in the previous sequence, and judge whether there is a sharp fluctuation in the thickness of silicon steel according to the thickness data of silicon steel. In severe cases, use the second-flow AGC and monitoring AGC for the first pass. If there are fluctuations in silicon steel performance but no severe fluctuations in silicon steel thickness, use feed-forward AGC, second-flow AGC, ...

Embodiment 2

[0077] The embodiment of the present invention discloses a cold-rolled silicon steel thickness control device based on full process data, including: a processor and a memory for storing a computer program that can run on the processor, wherein the processor is used to run the When the computer program is used, the steps of the above-mentioned method for controlling the thickness of cold-rolled silicon steel based on the whole process data are executed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com