Pulverizer for freezing and superfine grinding of traditional Chinese medicinal materials

An ultra-fine pulverizer and ultra-fine pulverizing technology, which are applied in cleaning methods and utensils, cleaning hollow objects, grain processing and other directions, can solve the problems of cumbersome cleaning work, low cleaning efficiency and general effect, and achieve increased cleaning effect. Good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

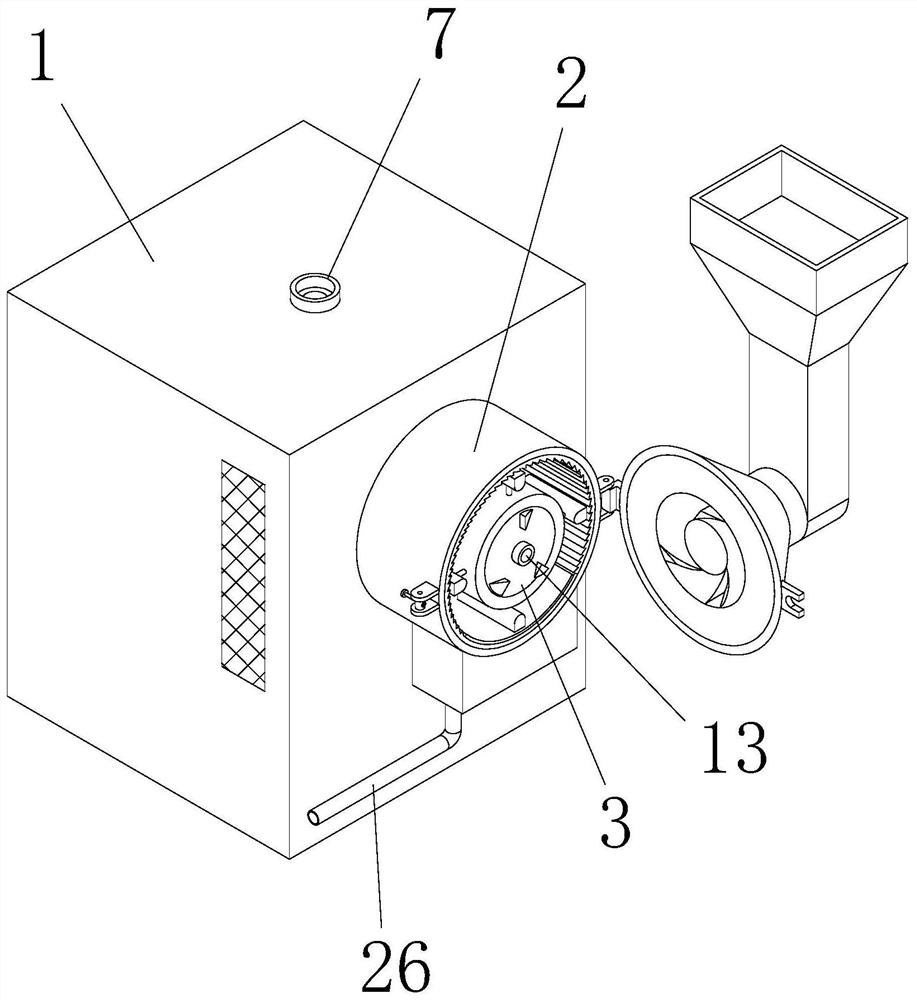

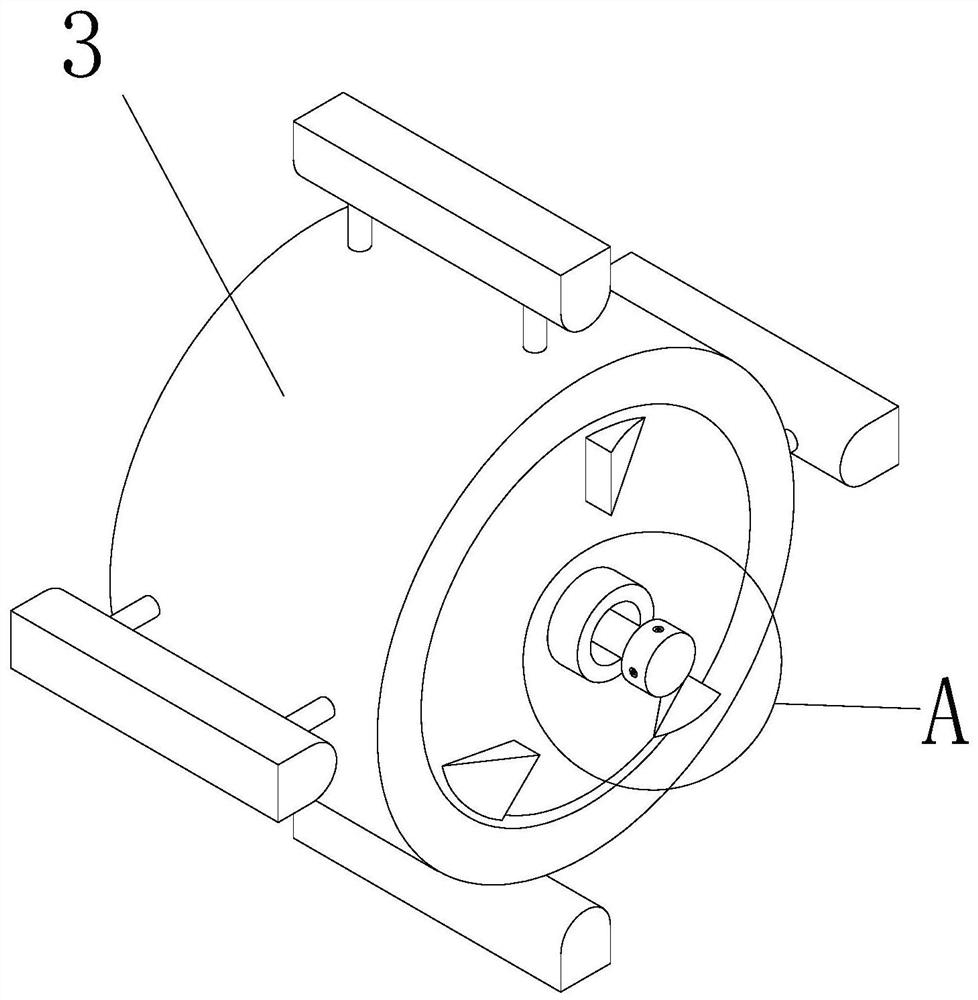

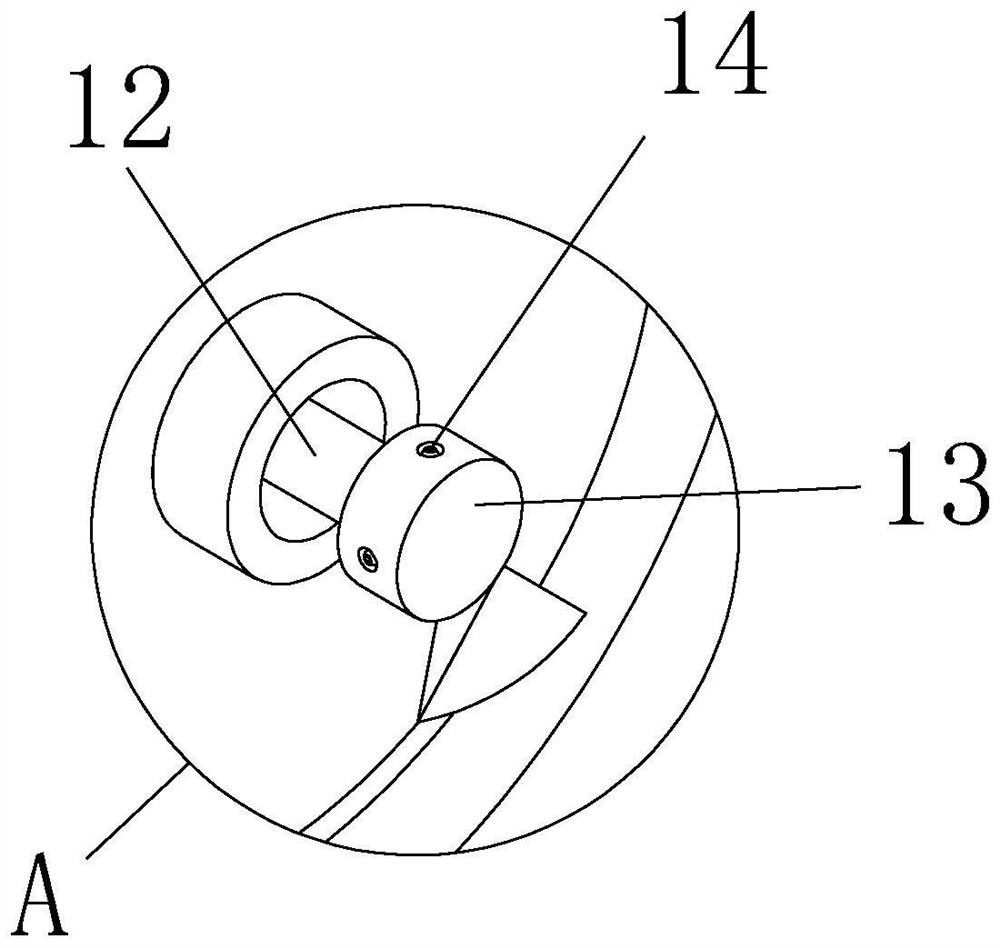

[0033] Embodiment: based on the pulverizer used for freezing ultrafine pulverization of Chinese herbal medicines, such as Figure 1-Figure 6 As shown, it includes a refrigerated ultrafine pulverizer body 1, the right end of the refrigerated ultrafine pulverizer body 1 is provided with a pulverizing bin 2, and a pulverizing drum 3 is arranged in the pulverizing bin 2, and the center of the right side of the pulverizing drum 3 is movably inserted into a set. The water tray 13, the outer wall of the water collection tray 13 is provided with a front cleaning nozzle 14, and the right side of the freezing superfine pulverizer body 1 is movable to be inserted with a cleaning ring 19, and the cleaning ring 19 is provided with a rear cleaning nozzle 21. A water tank 6 is arranged on the inner top of the ultrafine pulverizer body 1, and the bottom surface of the water tank 6 is fixedly inserted with a sewer pipe 8, and the right bottom end of the sewer pipe 8 is fixedly encased with a te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com