Degradable magnesium mesh for 3D printing personalized alveolar bone defect reconstruction

A 3D printing, alveolar bone technology, applied in 3D printing, skull, application, etc., can solve the problems of mesh distortion on the surface of magnesium mesh, damage to the mechanical properties of magnesium mesh, and affect the degradation performance of magnesium mesh, so as to solve stress shielding, Excellent self-supporting effect, the effect of improving the success rate of surgery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

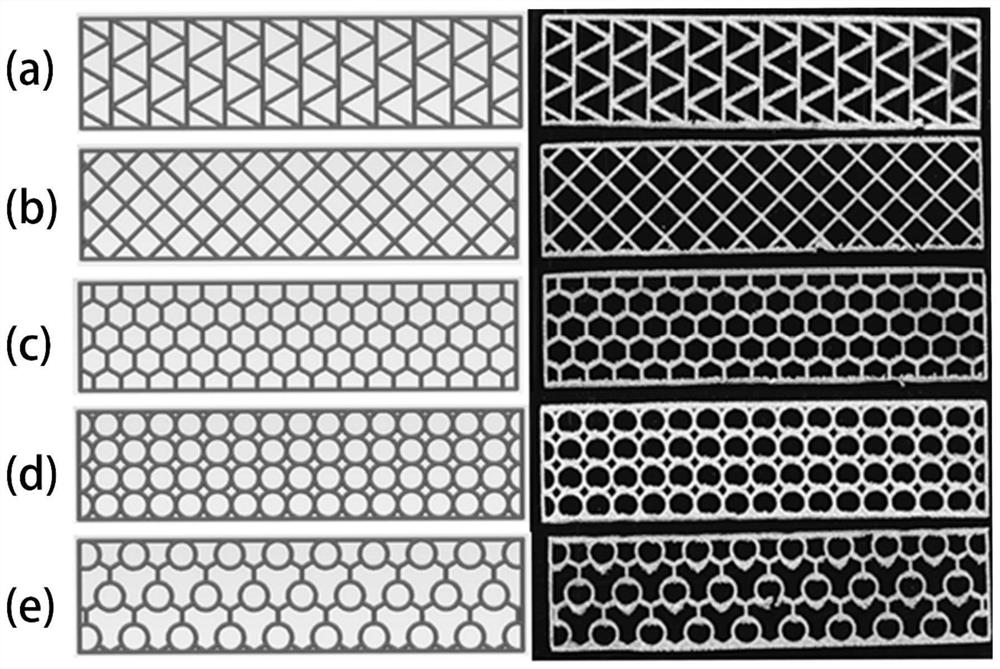

[0049] Embodiment 1, design and preparation of different mesh structure magnesium nets

[0050] Using 3-matic12.0 software (Materialise, Belgium) to design five support nets with different pore structures, the mesh structures are triangle, quadrilateral, hexagon, circle, and honeycomb circle, and the maximum mesh size is 2mm. Due to the specific structure of the personalized magnesium mesh, it is not easy to measure its mechanical properties, so the flat mesh is used as an equivalent replacement here. According to the national standard GB / T 232-2010 metal material bending test method, the standard test of the flat mesh is designed The length and width of the sample are 40mm and 20mm respectively, and the thickness is designed to be 0.4mm. It is prepared by laser powder bed melting technology, and the material used is Mg-3wt.%Nd-0.2wt.%Zn-0.5wt.%Zr magnesium alloy material .

[0051] The three-dimensional model of the flat screen sample and the corresponding printed physical...

Embodiment 2

[0052] Embodiment 2, the mechanical property test of magnesium mesh with different mesh structures

[0053] According to the GB / T 232-2010 bending standard, the flat magnesium mesh with different hole structures prepared in this example 1 was subjected to a mechanical bending test using a universal testing machine, and the applied load was perpendicular to the flat mesh at a rate of 1 mm / min. , until the magnesium mesh sample is destroyed.

[0054] Record the load (N) and real-time beam displacement (mm) of the magnesium mesh sample to obtain the load-displacement curve, and use the formula to calculate the flexural strength and flexural stiffness of the magnesium mesh sample. The data results are shown in Table 1. It can be seen that the magnesium mesh with hexagonal mesh and circular mesh has the greatest bending strength and flexural stiffness; while the magnesium mesh with triangular and honeycomb circular mesh has the worst bending mechanical properties. Considering th...

Embodiment 3

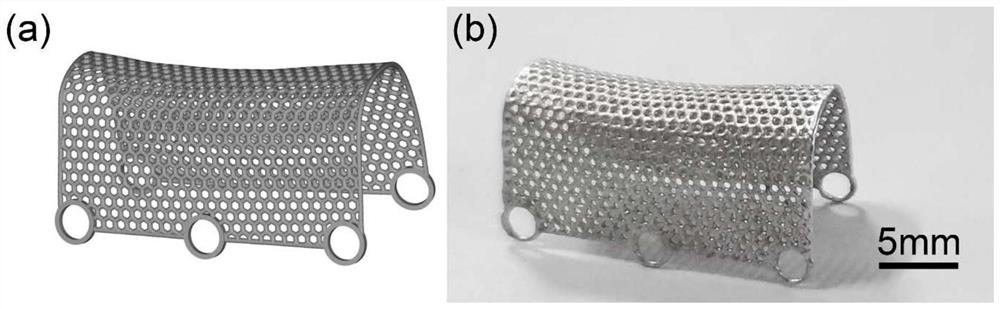

[0057] Embodiment 3, design and preparation of regular hexagonal mesh pure magnesium mesh

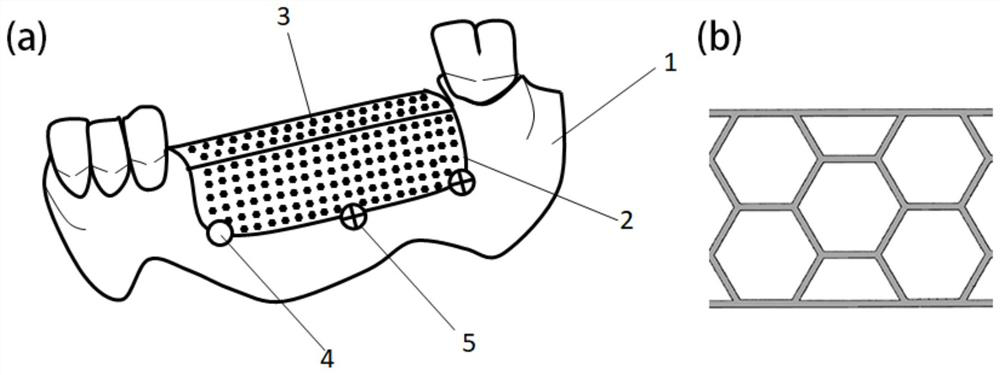

[0058] This embodiment relates to a degradable magnesium mesh used for alveolar bone defect reconstruction, figure 2 (a) is a schematic diagram of the overall structure of this embodiment, including an alveolar bone 1 and a magnesium mesh 2, the surface of the alveolar bone 1 has a bone defect, the magnesium mesh 2 completely covers the bone defect, and the magnesium mesh The surface of 2 is provided with evenly distributed mesh holes 3, and the magnesium mesh 2 is connected and fixed to the alveolar bone 1 through the fixing holes 4 and fixing screws 5 opened at the bottom. figure 2 (b) is a schematic diagram of the structure of the magnesium mesh.

[0059] The length of the magnesium mesh is 100mm, the height is 15mm, and the thickness is 0.5mm. The mesh is a regular hexagon with an aperture of 1000 μm. The fixing hole is circular with an aperture of 3mm. The magnesium mesh and f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com