Dispersoid and application thereof in protein gel food

A protein gel and dispersoid technology, applied in the food field, can solve the problems of complex process, inability to sterilize, heat and melt, etc., and achieve the effect of stabilizing the structure, forming and stabilizing the form of protein gel food.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

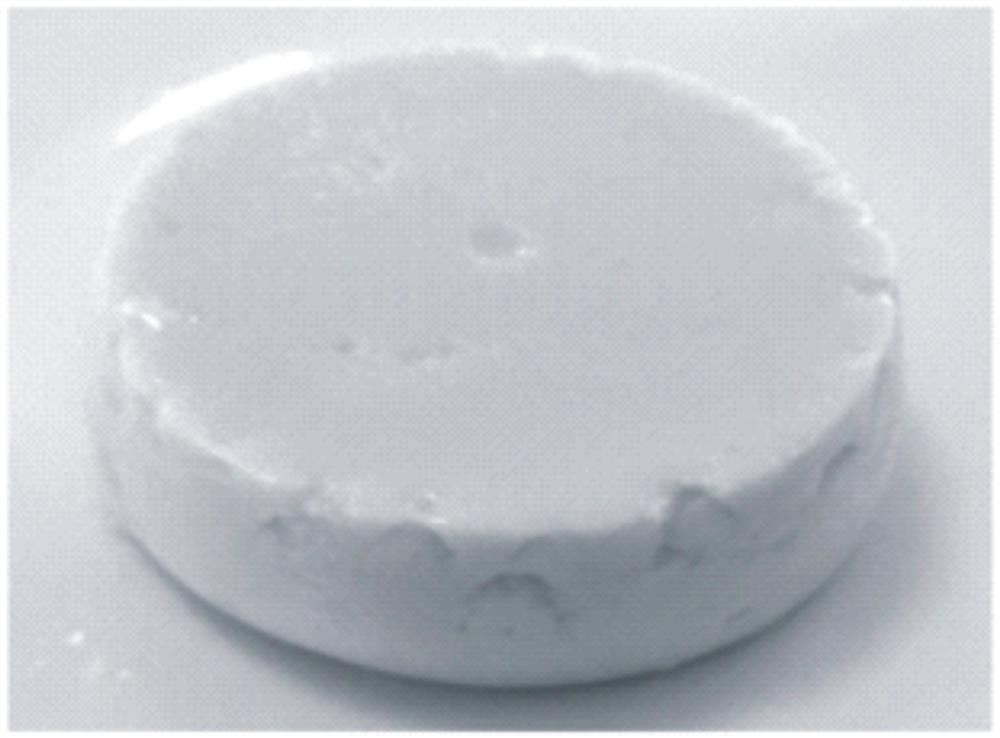

Image

Examples

preparation example Construction

[0037] In the preparation process of protein gel food, in order to shape and stabilize the product, it is often necessary to add animal polysaccharides as dispersants to form colloids in the entire protein gel system, so as to promote the formation of protein gel food gel, increase the Thickness improves product stability, but when the above dispersants are applied, it is often necessary to add whipped cream, butter, condensed milk and other substances to achieve better molding and product stability, and the process is more complicated.

[0038] The dispersoid disclosed in this application is composed of chlorella powder and milk powder. When it is dissolved in water, the protease contained in the chlorella powder cooperates with the sodium caseinate and other substances in the milk powder to make the whole protein system form a The special gel structure can replace the animal polysaccharide dispersant used in the preparation of the existing protein gel food.

[0039] For exam...

Embodiment 1

[0042] Example 1 Comparison of gel properties

[0043] Select commercially available animal polysaccharide dispersants commonly used in mousse products: agar, gelatin, and the application of chlorella powder plus milk powder (① 0.2 parts of chlorella powder, 25 parts of Wilson instant milk powder; ② 0.6 parts of chlorella powder , 32 parts of Weiersheng instant milk powder; ③1 part of chlorella powder, 40 parts of Weiersheng instant milk powder) as a dispersoid, add water 20 times the mass of the dispersing matter, and place it in a constant temperature incubator at 10°C for 16-18 hours. Then the gel strength of the colloid was measured with a texture analyzer.

[0044] The measurement parameters are as follows: the probe is P / 0.5R, and the test speed is 1mm / s. The gel strength is the maximum pressure that the probe can bear when pressing down on the gel 4mm. The test results are shown in Table 1:

[0045] Table 1 Gel strength of different colloids

[0046] .

[0047] As...

Embodiment 2

[0056] Preparing protein gel foods

[0057] 1. Mix 3kg of soybean protein isolate, 1kg of dispersoid (Example 1-2 contains dispersoid of 0.6 parts of chlorella powder and 32 parts of Weiersheng instant milk powder), 20kg of water, chop and mix at high speed for 6 minutes for the first time, chop and mix The speed is 3000rpm;

[0058] 2. Add 0.75kg of soybean oil and 0.75kg of white sugar to the material after the first high-speed chopping and mixing, and the second high-speed chopping and mixing for 6 minutes at a rate of 3000rpm;

[0059] 3. Put the material after the second chopping into the mold and seal it, place it in a constant temperature box at 55°C, and shape it for 2.5 hours;

[0060] 4. After molding, it is pasteurized at 85°C for 18 minutes to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com