Alum-free vermicelli and making method thereof

A production method and technology of alum powder, applied in the direction of food ingredients as a taste improver, food science, etc., can solve the problems of insufficient strength and poor taste of alum-free vermicelli, achieve good toughness and gloss, solve health risks, and taste smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

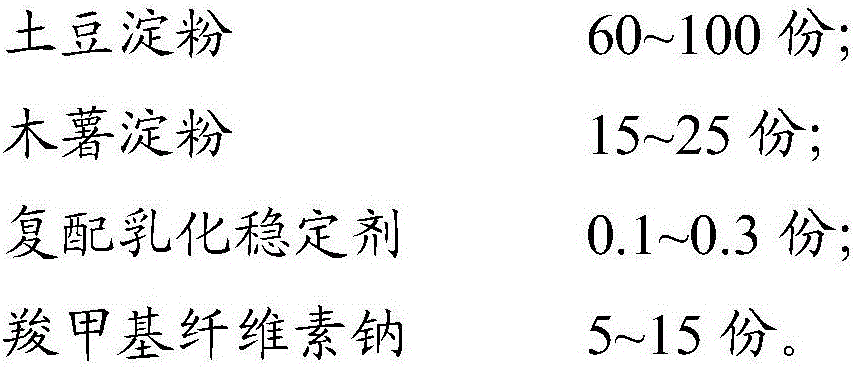

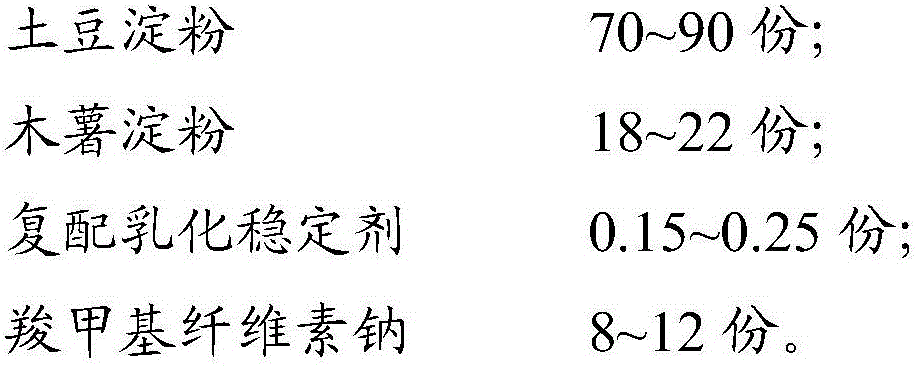

[0046] The potato starch is divided into two parts, respectively the first part of potato starch and the second part of potato starch, the quality of the first part of potato starch is 6kg, and the quality of the second part of potato starch is 2kg;

[0047] Get the first portion of potato starch and 1.5kg of tapioca starch, mix them evenly, then add 0.01kg compound emulsification stabilizer and 0.5kg carboxymethyl cellulose sodium in parts by weight, mix evenly to obtain a mixed substance; compound emulsification stabilizer Contains 0.5g carrageenan, 2.5g complex phosphate, 5g sucrose ester and 2g hydroxylated modified soybean lecithin;

[0048] Add the second portion of potato starch into warm water at 50°C to make a paste, and add boiling water at 80°C to the starch paste while stirring until the starch paste is transparent and uniform;

[0049] Put the container filled with transparent and uniform starch into a boiling water pot, the temperature in the boiling water pot is...

Embodiment 2

[0052] The potato starch is divided into two parts, respectively the first part of potato starch and the second part of potato starch, the quality of the first part of potato starch is 4.5kg, and the quality of the second part of potato starch is 1.5kg;

[0053]Get the first portion of potato starch and 2.5kg of tapioca starch, mix them evenly and add 0.03kg of compound emulsification stabilizer and 1.5kg of sodium carboxymethyl cellulose in parts by weight, mix uniformly to obtain a mixed substance; compound emulsification stabilizer Contains 3g carrageenan, 9g complex phosphate, 15g sucrose ester and 3g hydroxylated modified soybean lecithin;

[0054] Add the second portion of potato starch into warm water at 54°C to make a paste, and add boiling water at 100°C to the starch paste while stirring until the starch paste is transparent and uniform;

[0055] Put the container filled with transparent and uniform starch into a boiling water pot, the temperature in the boiling wate...

Embodiment 3

[0058] The potato starch is divided into two parts, respectively the first part of potato starch and the second part of potato starch, the quality of the first part of potato starch is 8.75kg, and the quality of the second part of potato starch is 1.25kg;

[0059] Get the first portion of potato starch and 1.8kg of tapioca starch, and then add the parts by weight of 0.015kg compound emulsification stabilizer and 0.8kg carboxymethyl cellulose sodium after mixing evenly to obtain a mixed substance; compound emulsification stabilizer Contains 1.5g carrageenan, 4.5g complex phosphate, 6g sucrose ester and 3g hydroxylated modified soybean lecithin;

[0060] Add the second portion of potato starch into warm water at 53°C to make a paste, and add boiling water at 95°C to the starch paste while stirring until the starch paste is transparent and uniform;

[0061] Put the container filled with transparent and uniform starch into a boiling water pot, the temperature in the boiling water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com