Mercury reduction reaction gas-liquid separation device for high-precision mercury isotope determination and use method

A mercury isotope, high-precision technology, used in the field of isotope measurement equipment improvement, can solve problems such as inability to disassemble, difficult to clean, and small reduction reaction interface, and achieve the effects of facilitating gas release, reducing operating costs, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with the examples, the present invention is further described, the following examples are illustrative, not limiting, and the protection scope of the present invention cannot be limited by the following examples.

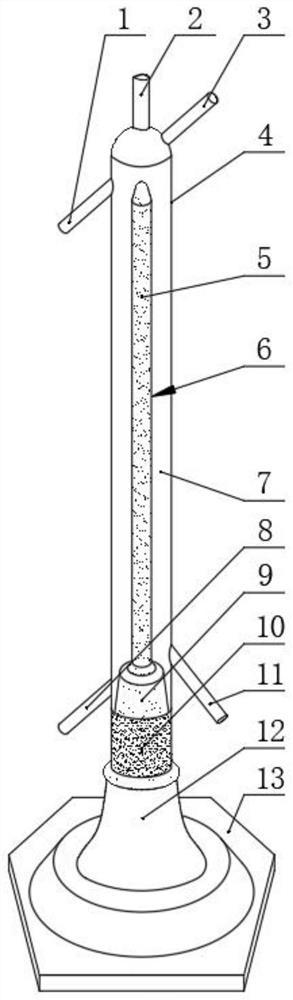

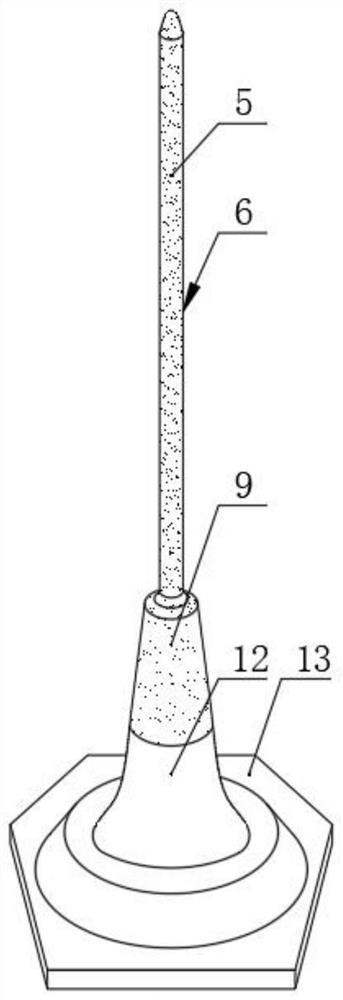

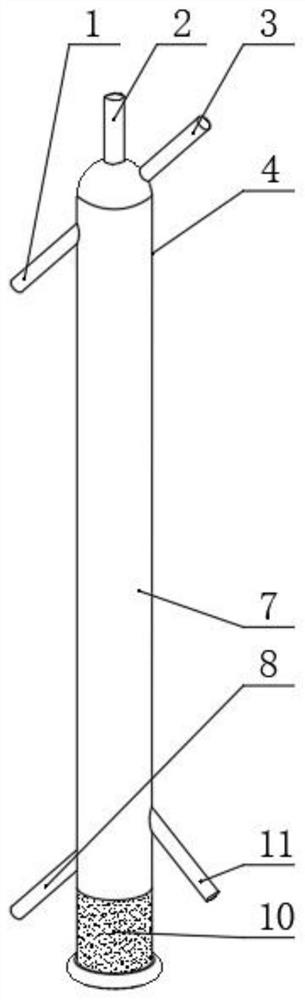

[0030] A mercury reduction reaction gas-liquid separation device for mercury isotope determination, such as Figure 1-3 As shown, the innovation of the present invention is: comprising an outer casing 4 and a reaction tube 5, the upper end of the outer casing is provided with a reactant outlet 3 communicating with the inner cavity of the outer casing, a proofreading sample inlet 1 and a feed port 2, and the lower end of the outer casing is provided with There is a gas inlet 11; the outer surface of the reaction tube is provided with a frosted surface 6, and the lower end of the reaction tube is provided with a connecting part 12, which is used for sealing connection with the opening at the lower end of the outer casing.

[0031] The feedi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com