Three-microwave multi-wheel cooperative coiled material paving vehicle and paving method thereof

A collaborative, coiled material technology, applied in the direction of roads, road repairs, roads, etc., can solve problems such as low efficiency and manpower consumption, and achieve the effects of promoting bonding and fusion, improving efficiency, and simplifying construction procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

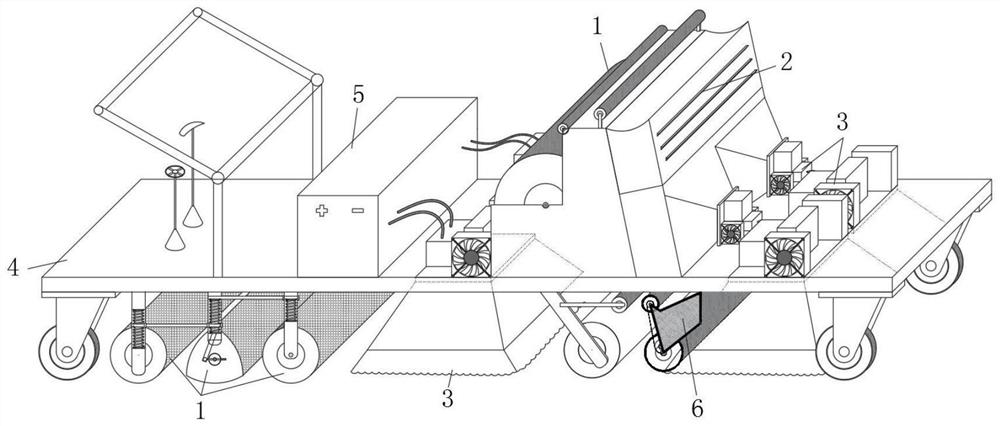

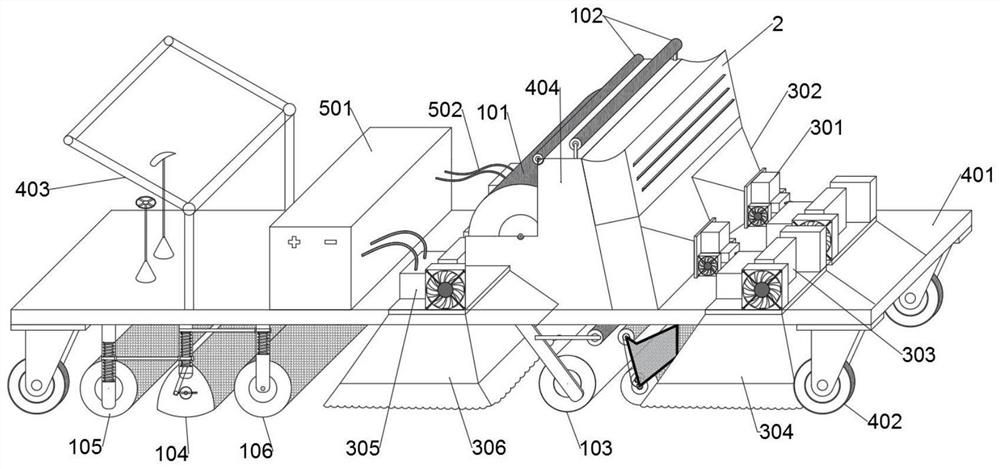

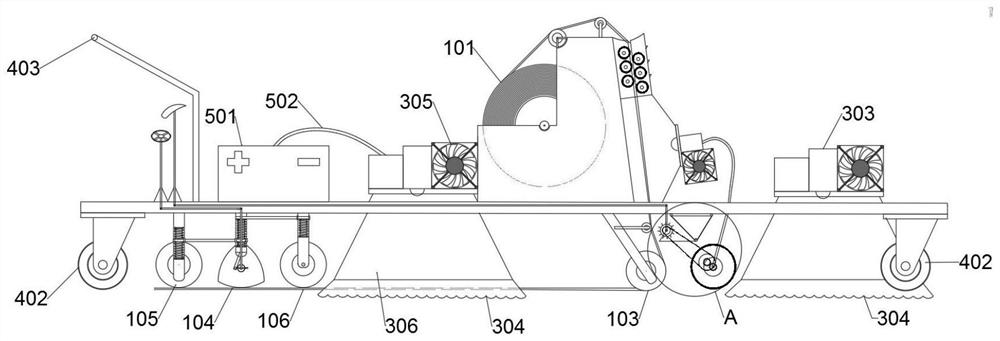

[0032] refer to Figure 1-7, a three-microwave multi-wheel cooperative coil paving vehicle, comprising a trolley body 4, a rolling device assembly 1, an oiling device assembly 2, a microwave heating device 3 and a power supply assembly 5 are installed on the trolley body 4, the small The vehicle body 4 comprises a vehicle frame 401, four corners of the bottom surface of the vehicle frame 401 are equipped with universal wheels 402, a handlebar 403 is installed at the rear end of the vehicle frame 401, and a shift adjustment lever is installed on the vehicle frame 401 below the handlebar 403 And the frequency conversion control wheel, the middle part of the top surface of the vehicle frame 401 is fixed with a placement frame 404, the inner side of the bottom of the placement frame 404 is equipped with a waterproof coiled material 101, and the top side of the placement frame 404 is rotatably connected with guide rollers 102, and the guide rollers 102 are provided with three. The ...

Embodiment 2

[0035] Such as figure 1 and 2 As shown, this embodiment is basically the same as Embodiment 1. Preferably, there are two microwave heaters 1 301 and they are all heated backwards. In the side position, the microwave heating direction of the second microwave heater 303 is downward, and two of the third microwave heater 305 are arranged symmetrically on the front and rear sides of the top of the vehicle frame 401.

[0036] In this embodiment, there are two microwave heaters one 301, two microwave heaters 303 and three microwave heaters 305, so as to realize the comprehensive heating of the coiled material and the paved road surface, thereby ensuring the coiled material to be laid well. quality.

Embodiment 3

[0038] Such as Figure 4 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the rotation of the variable frequency control wheel can control the range of movement of the reciprocating link assembly, thereby controlling the height of the power piston.

[0039] In this embodiment, the frequency conversion control wheel rotation can control the moving range of the reciprocating link assembly, thereby controlling the lifting height and rolling force of the rolling wheel 105, thereby meeting the requirements of different laying environments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com