Connector injection molding production system

A technology for production systems and connectors, applied in chemical instruments and methods, smoke removal, cleaning methods and utensils, etc., can solve problems such as affecting the health of surrounding workers, pungent exhaust gas, etc., to increase the removal range and reduce the impact. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

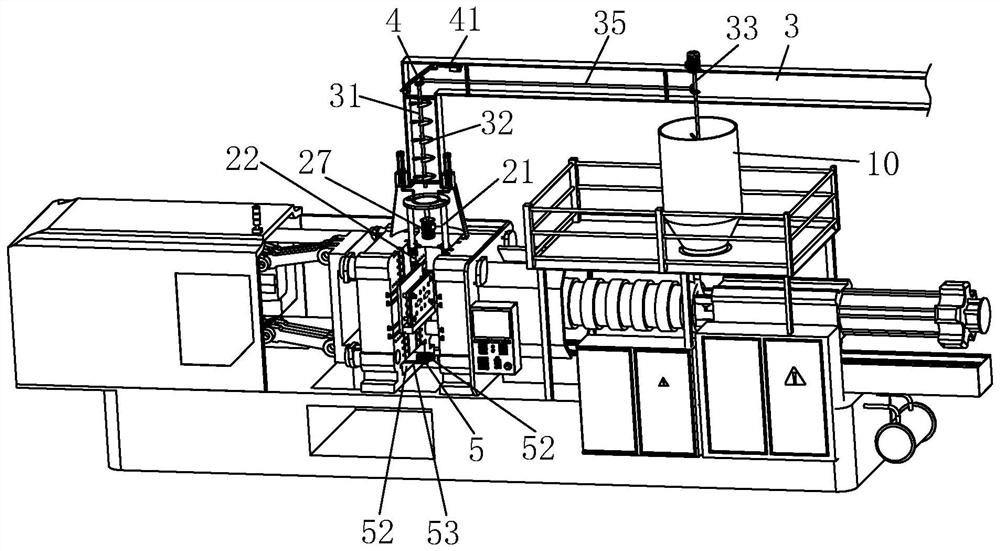

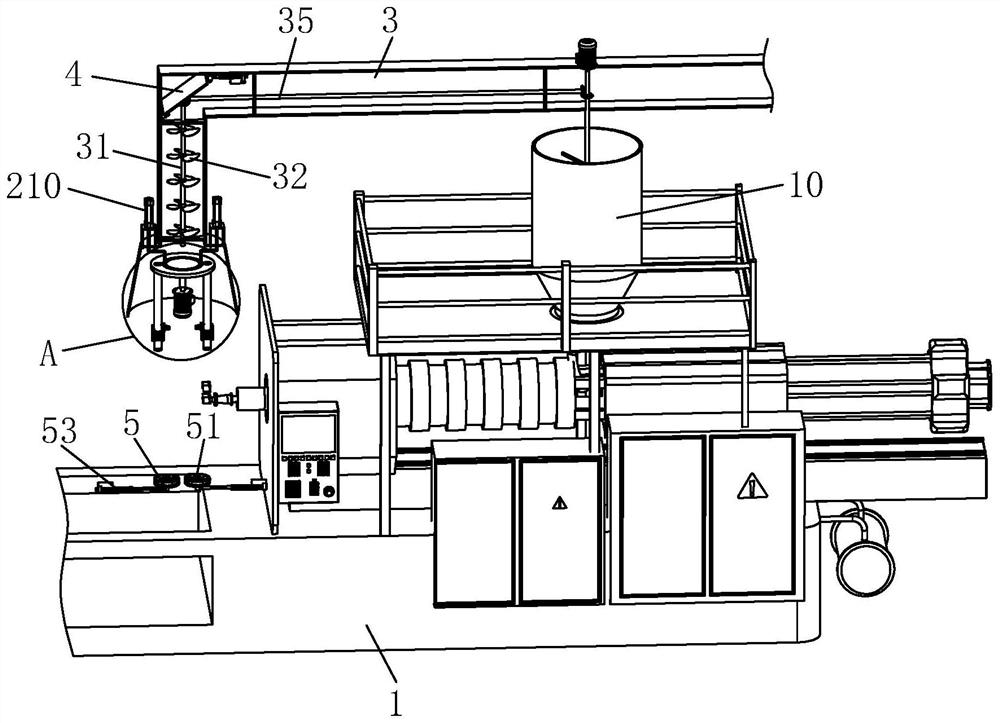

[0035] The application will be described in further detail below in conjunction with the accompanying drawings.

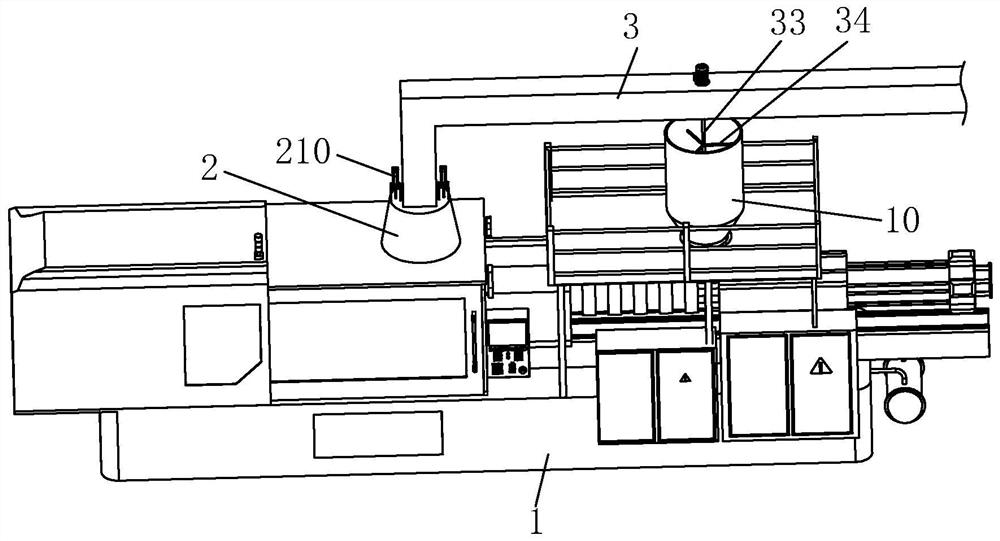

[0036] The embodiment of the present application discloses a connector injection molding production system, such as figure 1 and figure 2 As shown, it includes: an injection molding machine body 1, a feed hopper 10 is installed on the injection molding machine body 1, and plastic particles enter the injection molding machine body 1 through the feed hopper 10, on the side of the injection molding machine body 1 away from the feed hopper 10 A box body 2 is installed on the top, and the box body 2 is installed on the top shell of the injection molding machine body 1, and the bottom of the box body 2 is provided with an exhaust port, and the exhaust port communicates with the interior of the injection molding machine body 1.

[0037] An exhaust pipe 3 is installed on the top of the box body 2, and the end of the exhaust pipe 3 away from the box body 2 can be connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com