Leakage-proof lubricating grease for gear coupling and preparation method thereof

A technology of lubricating grease and coupling, applied in the field of lubricating oil, can solve problems such as difficulty in realizing maintenance cost of oil leakage failure of coupling, large workload in disassembling coupling, and difficulty in ensuring sealing quality, etc., and achieve excellent extreme pressure Anti-wear properties, reduced maintenance costs, easy-to-manufacture results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

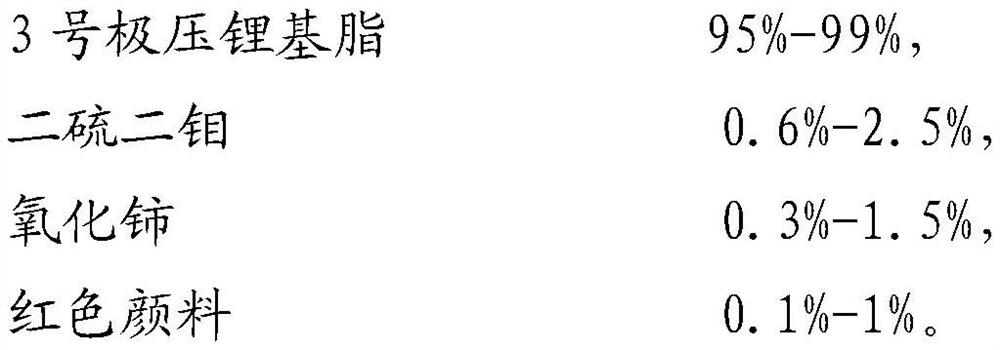

[0019] A kind of anti-leakage lubricating grease for gear couplings, comprising the following components in mass percentage:

[0020]

[0021] Its preparation method is to add No. 3 extreme pressure lithium base grease, molybdenum disulfide, cerium oxide and red pigment to the 20Cr stainless steel blending kettle in sequence, stir at 800r / min at 120°C for 1.5h, and then degas the blending kettle Treat for 15 minutes to obtain the anti-leakage grease.

Embodiment 2

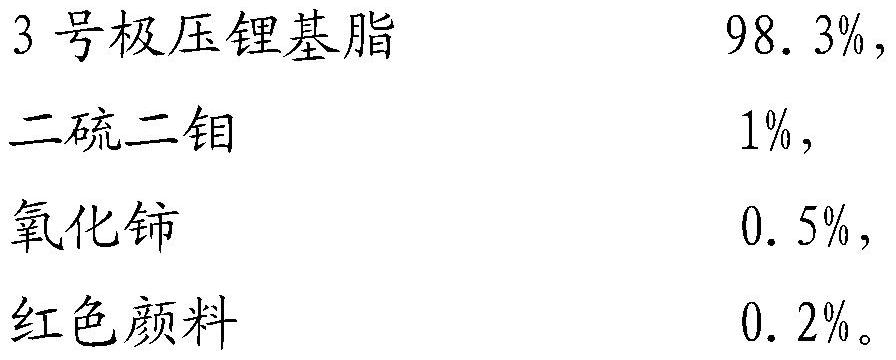

[0023] A kind of anti-leakage lubricating grease for gear couplings, comprising the following components in mass percentage:

[0024]

[0025] The preparation method is: add No. 3 extreme pressure lithium base grease, molybdenum disulfide, cerium oxide and red pigment to a 20Cr stainless steel blending kettle in sequence, stir at 900r / min at 120°C for 2 hours, and then degas the blending kettle After 20 minutes, the leak-proof grease is obtained.

Embodiment 3

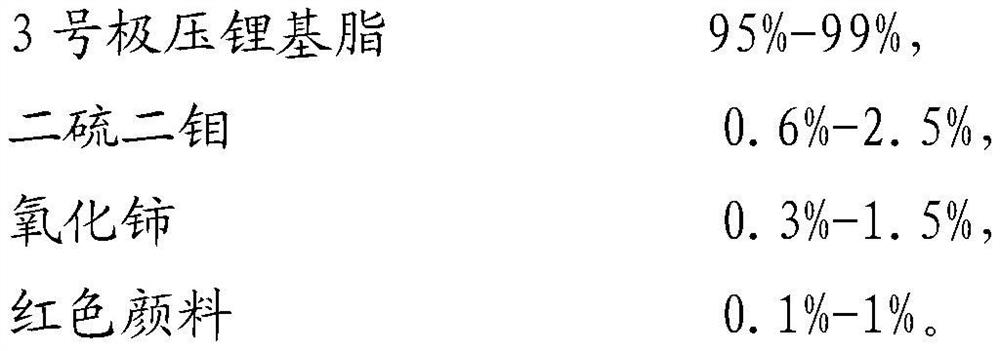

[0027] A kind of anti-leakage lubricating grease for gear couplings, comprising the following components in mass percentage:

[0028]

[0029] The preparation method is: add No. 3 extreme pressure lithium base grease, molybdenum disulfide, cerium oxide and red pigment to a 20Cr stainless steel blending kettle in sequence, stir at 120°C at 1000r / min for 2 hours, and then degas the blending kettle After 20 minutes, the leak-proof grease is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com