Pneumatic tire

A technology of pneumatic tires and tires, which is applied to special tires, tire parts, tire treads/tread patterns, etc., and can solve problems such as insufficient handling stability and ride comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0187] Although the present invention is specifically described based on examples, the present invention is not limited to these examples.

[0188] Hereinafter, various agents used in Examples and Comparative Examples are collectively shown.

[0189] SBR1: S-SBR produced in Production Example 1 described later (styrene content: 30 mass%, vinyl content: 52 mol%, Mw: 250,000, non-oil-extended)

[0190] SBR2: HP755 manufactured by JSR Corporation (S-SBR; styrene content: 40% by mass, vinyl content: 38% by mole, oil-extended product containing 37.5 parts by weight of oil per 100 parts by weight of the rubber component)

[0191] BR1: UBEPOL BR (registered trademark) 150B manufactured by Ube Industries, Ltd. (cis content: 97%, Mw: 440,000)

[0192] BR2: BR500 manufactured by JSR Corporation (cis content: 32%)

[0193] Carbon black: Diablack N220 (N 2 SA: 115m 2 / g)

[0194] Silica: ULTRASIL (registered trademark) VN3 (N) manufactured by Evonik Degussa 2 SA: 175m 2 / g)

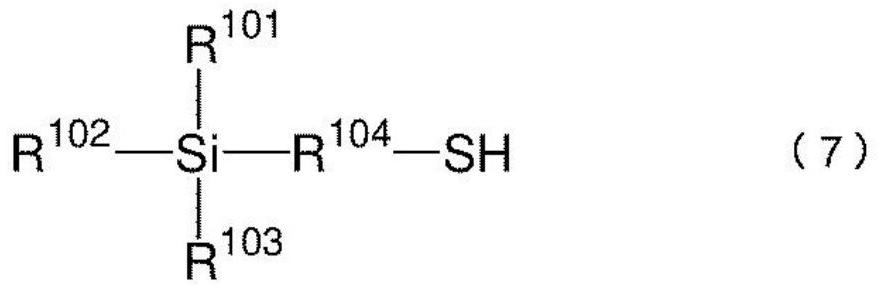

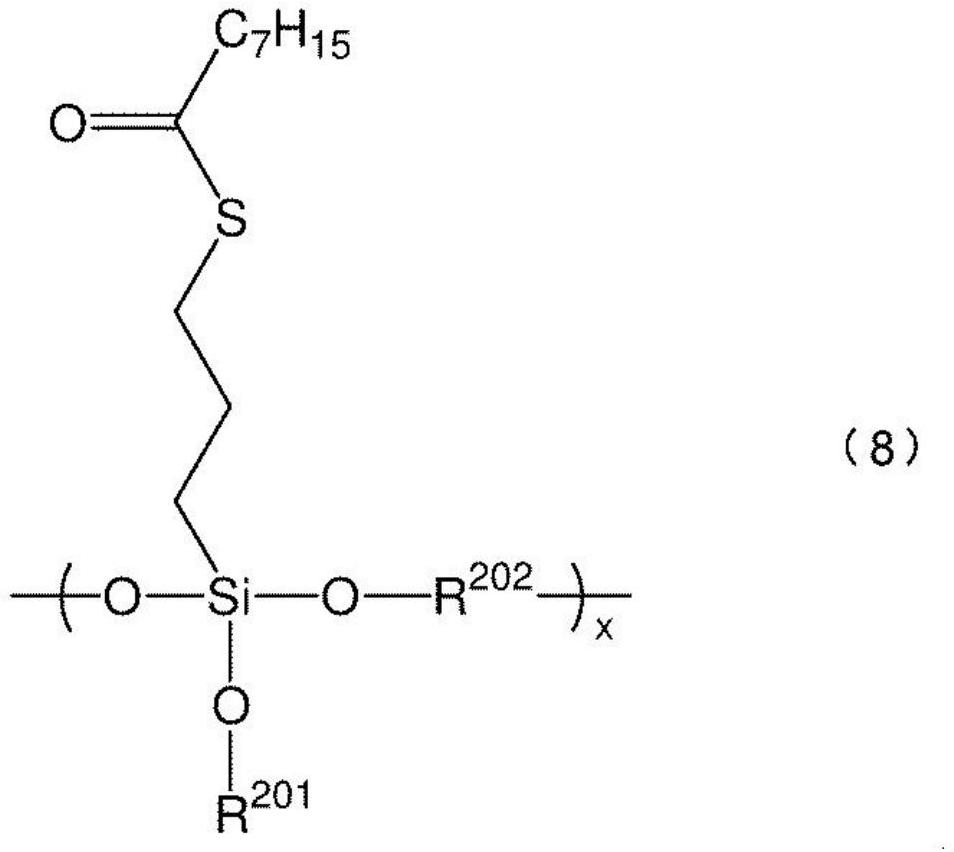

[019...

manufacture example 1

[0205] Production Example 1: Synthesis of SBR1

[0206] Cyclohexane, tetrahydrofuran, styrene and 1,3-butadiene were charged into the nitrogen-purged autoclave reactor. After adjusting the temperature of the contents of the reactor to 20° C., n-butyllithium was added to start polymerization. Polymerization under adiabatic conditions with a maximum temperature of 85°C. When the polymerization conversion rate reached 99%, 1,3-butadiene was added, and after another 5 minutes of polymerization, N,N-bis(trimethylsilyl)-3-aminopropyltrimethoxysilane was used as a modification Agents are added and reacted. After the polymerization reaction was completed, 2,6-di-tert-butyl-p-cresol was added. Next, solvent removal was carried out by stripping, and drying was carried out with a hot roll adjusted to 110° C. to obtain SBR1.

[0207] Based on the compounding contents shown in Table 1, sulfur and chemicals other than the vulcanization accelerator were kneaded at a discharge temperature o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com