Air spring for moving body and moving body vehicle using the air spring

An air spring and moving body technology, applied in the field of air springs, can solve the problems of complex structure and increased cost, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

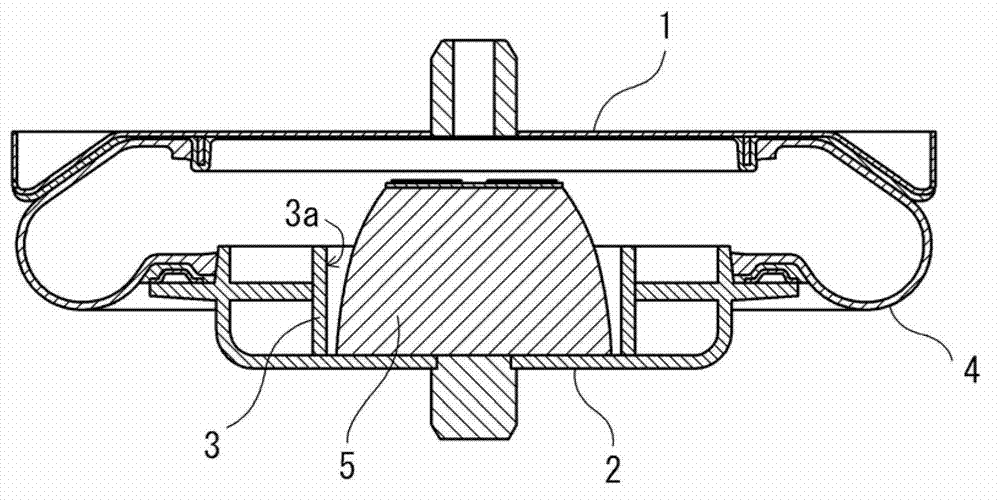

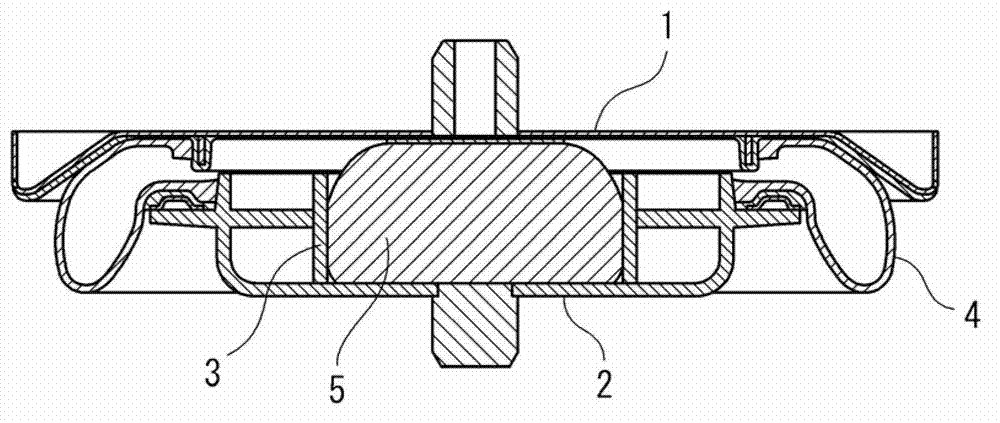

[0045] The structure of the air spring according to the present invention will be described with reference to the drawings. In addition, elements marked with the same reference numerals in different drawings represent the same or corresponding elements. The present invention is not limited to these configurations but is shown by the claims, and includes the same contents as the claims and all modifications within the scope thereof.

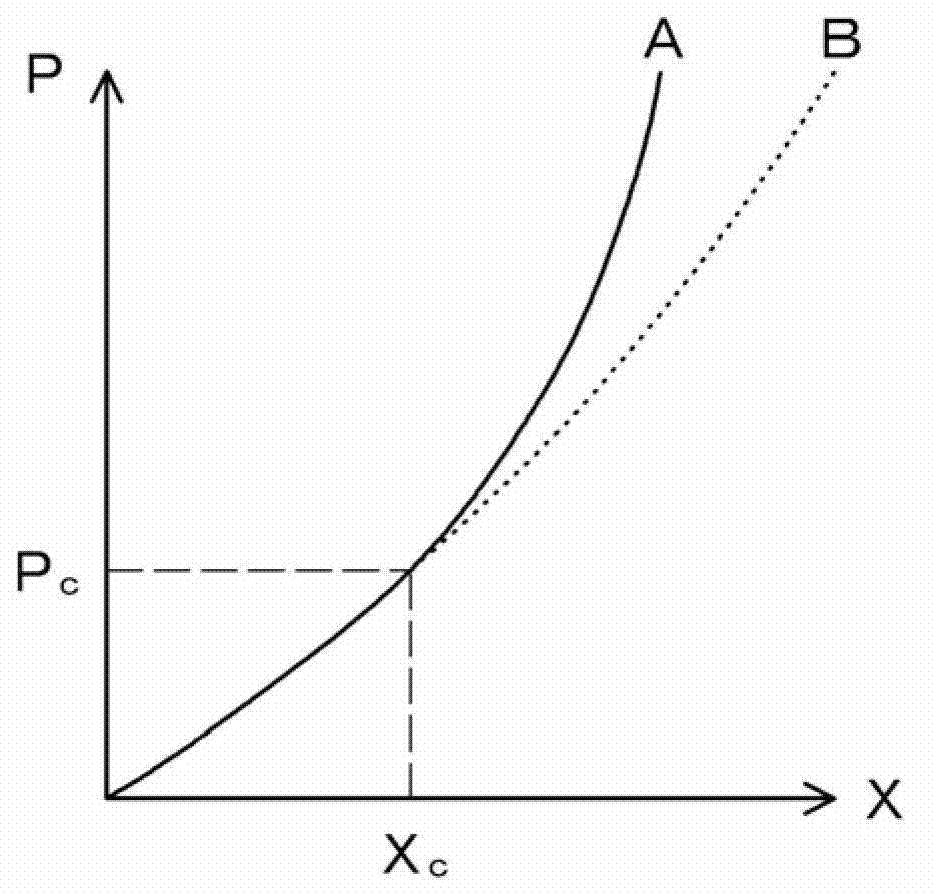

[0046] figure 1 It is a schematic cross-sectional view showing an air spring as an example of the present invention. figure 1 Shows a cross section of the air spring cut along a vertical plane passing through its central axis, and does not show a plan view or a bottom view, but the overall shape is a circular shape rotated around the central axis. use figure 1 The basic structural elements of the present invention and their functions will be described. The basic structure of the air spring is composed of a diaphragm 4, and the upper and lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com