Fuel cell membrane electrode and preparation method thereof

A fuel cell membrane and electrode technology, which is applied in the direction of fuel cells, battery electrodes, circuits, etc., can solve the problems of difficult control of product uniformity and high requirements for replacement reaction control conditions, so as to reduce material costs, improve performance and quality, The effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

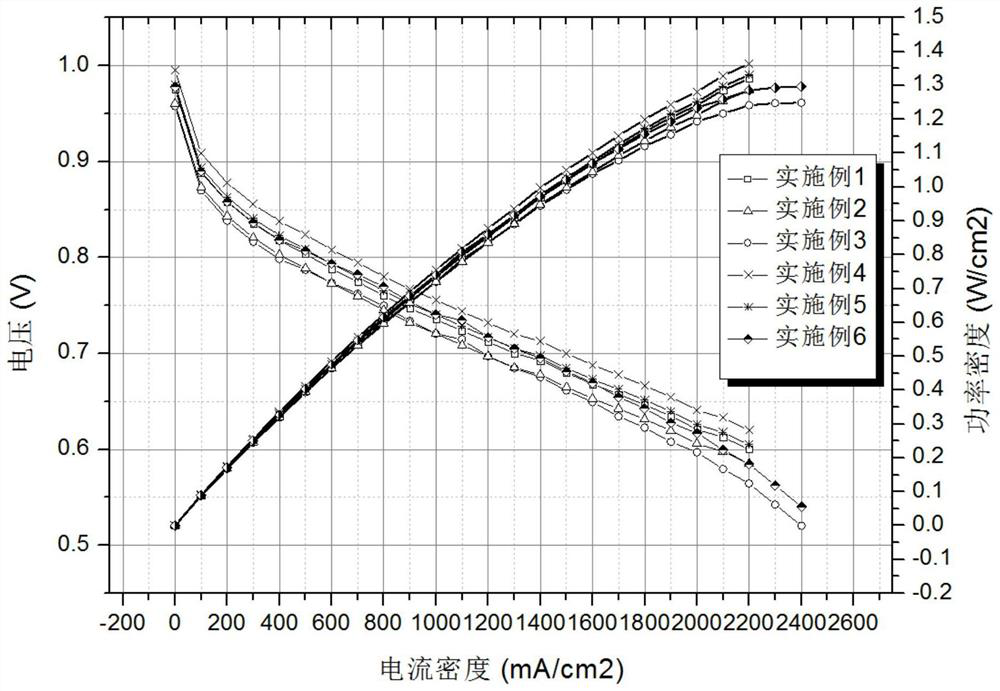

Embodiment 1

[0029] Fibrous catalyst preparation: get platinum carbon catalyst (platinum load 50%, brand TKK, model 10E50E) 1g, deionized water 20g and op10 emulsifier 0.1g mix ultrasonic 30 minutes, then nano-dispersion equipment (high pressure homogeneous AH- 1500) 40mpa high-pressure treatment for 30 minutes to obtain nanoparticle slurry, take out the nanoparticle slurry and add 1g of treated carbon nanofibers for 10 minutes of ultrasonic dispersion, and then use IKA T25 equipment for high-speed shearing for 30 minutes to deposit and load, and then put it in an oven at 65°C Grind after drying.

[0030] Take by weighing 20 mg of fibrous catalyst and put it in a 50 ml beaker, add 10 g of deionized water to completely wet the catalyst, then add 100 mg of nafion solution (brand Dupont, model d520) with a mass concentration of 5% and 15 g of n-propanol in the beaker, and place the beaker at Constant-temperature ultrasonication in a constant-temperature ultrasonicator for 20 minutes, and then...

Embodiment 2

[0034]Preparation of fibrous catalyst: get platinum carbon catalyst (platinum loading 50%, brand TKK, model 10E50E) 1g, deionized water 20g, n-propanol 15g and op10 emulsifier 0.05g and mix ultrasonically for 30 minutes, then nano-dispersion equipment ( High-pressure homogenization (AH-1500) 40mpa high-pressure treatment for 30 minutes to obtain nanoparticle slurry, take out the nanoparticle slurry and add 0.8g of processed carbon nanofibers for 10 minutes of ultrasonic dispersion, and then use IKA T25 equipment for high-speed shearing for 30 minutes to deposit and load , and then dried in an oven at 60°C and ground for use.

[0035] Take by weighing 0.1g of fibrous catalyst and put it in a 50ml beaker, add 10g of deionized water to wet the catalyst completely, then add 0.7g of nafion solution (brand Dupont, model d520) and 15g of n-propanol in the beaker with a mass concentration of 5%. Put the beaker in a constant temperature sonicator for constant temperature ultrasonicatio...

Embodiment 3

[0038] Preparation of fibrous catalyst: get platinum carbon catalyst (platinum loading 50%, brand TKK, model 10E50E) 1g, deionized water 15g, n-propanol 15g and op10 emulsifier 0.05g and mix ultrasonically for 30 minutes, then nano-dispersion equipment ( High-pressure homogenization (AH-1500) 40mpa high-pressure treatment for 50 minutes to obtain nanoparticle slurry, take out the nanoparticle slurry and add 0.5g of processed carbon nanofibers for 10 minutes of ultrasonic dispersion, and then use IKA T25 equipment for high-speed shearing for 40 minutes to deposit and load , and then dried in an oven at 60°C and ground for use.

[0039] Take by weighing 0.1g of fibrous catalyst and put it in a 50ml beaker, add 10g of deionized water to wet the catalyst completely, then add 0.7g of nafion solution (brand Dupont, model d520) and 15g of n-propanol in the beaker with a mass concentration of 5%. The beaker was placed in a constant temperature sonicator for constant temperature ultras...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com