Method for calculating allowable difference of sampling inspection result of stored coal sample

A coal sample and difference technology, applied in calculation, manufacturing calculation system, complex mathematical operation, etc., can solve the problems of calorific value loss, large difference, shrinking error in sample preparation stage, etc. The effect of improving the level of sample management and improving the level of coal combustion management and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

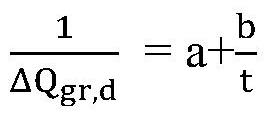

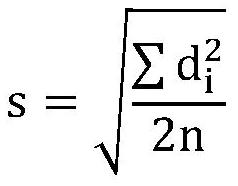

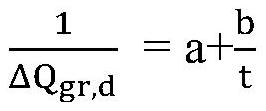

Method used

Image

Examples

Embodiment 1

[0074] Embodiment 1: Calculate the random inspection tolerance of the 3mm deposit and check coal sample of a certain mine A coal type in a certain factory:

[0075] (1) The first step: deposit and check coal samples Coal type: A coal type, nominal maximum particle size: 3mm, sample preparation process: GB / T474-2008, longest storage period: 3 months;

[0076] (2) The second step: according to the routine sampling method of the power plant, take the coal type A of the mine (the total amount is not less than the standard requirement, not less than 15kg), and prepare it according to the national standard sample preparation procedure with a nominal maximum particle size of 3mm and a good quality No less than 20 samples (10 pairs) weighing 700g and numbered (1A, 1B, 2A, 2B, ..., 10A, 10B);

[0077] (3) The third step: Prepare the prepared 1A and 1B samples according to the national standard sample preparation procedures into general analysis samples and test them to obtain the high ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com