Method for adjusting top pressure of blast furnace by means of BPRT unit

A technology of top pressure and unit, applied in the field of metallurgy, can solve the problems of unbalanced top pressure, poor reliability, and inability to guarantee the stability of blast furnace top pressure, so as to ensure stability, improve regulation level, and avoid the phenomenon of uncontrolled top pressure regulation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

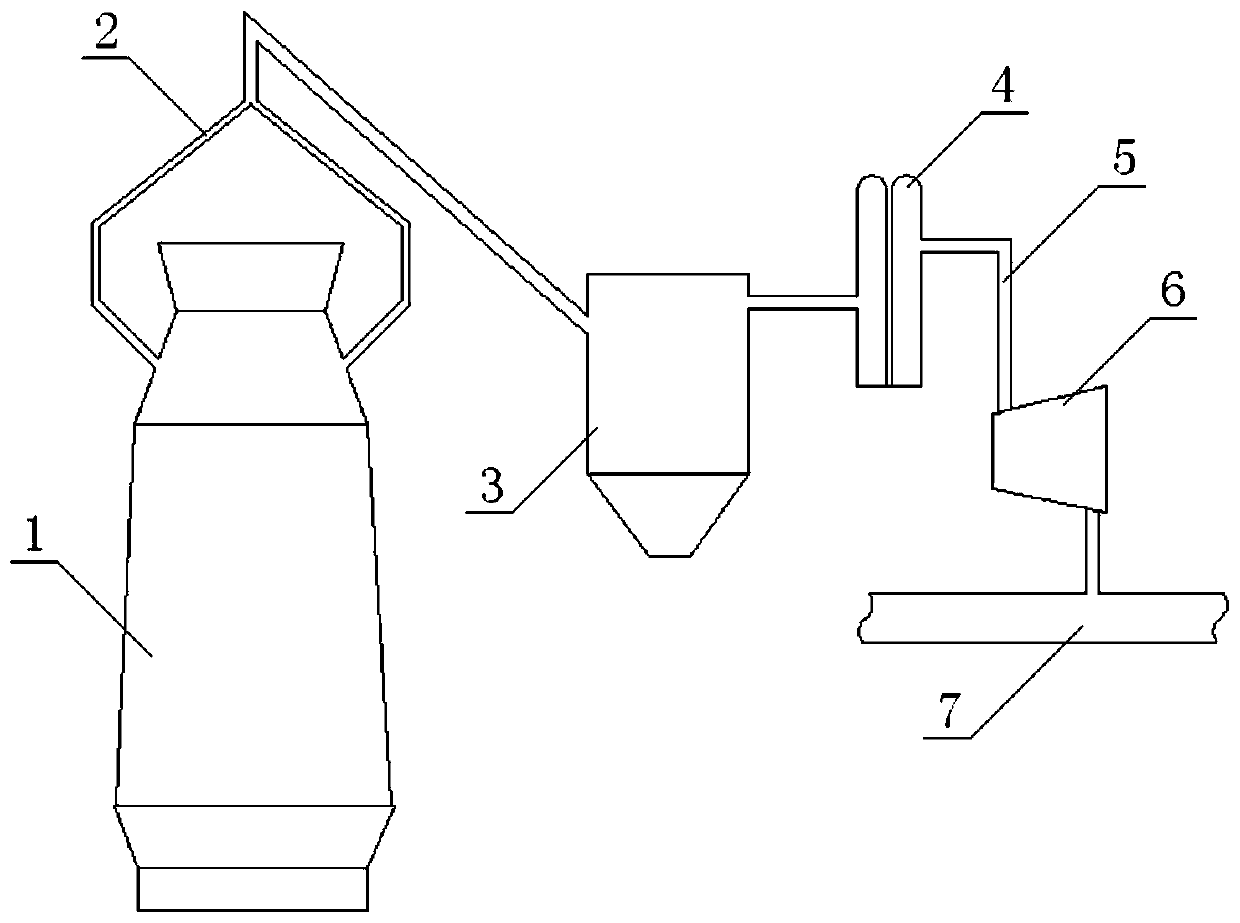

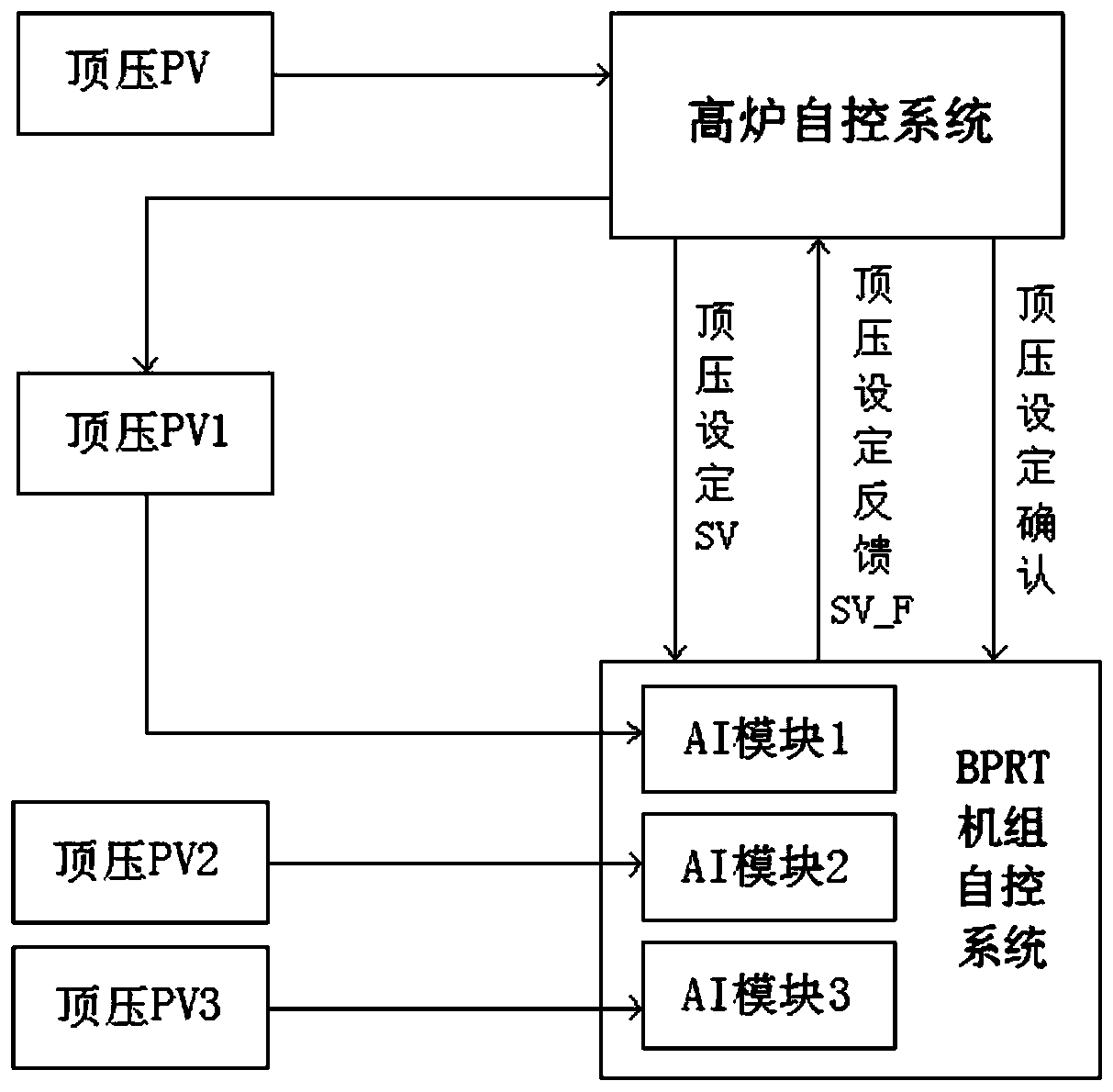

[0024] The invention provides a method for adjusting the top pressure of a blast furnace by using a BPRT unit. By improving the top pressure signal of the blast furnace and the selection mode of the top pressure setting value, the method effectively overcomes the out-of-control phenomenon of the top pressure adjustment caused by the easy distortion of a single signal source. , to solve the problems described in the background technology.

[0025] Compared with traditional methods, this method has the following characteristics:

[0026] 1. The number of blast furnace top pressure signals connected to the BPRT unit automatic control system is optimized to three;

[0027] 2. Optimize the collection method of the top pressure signal;

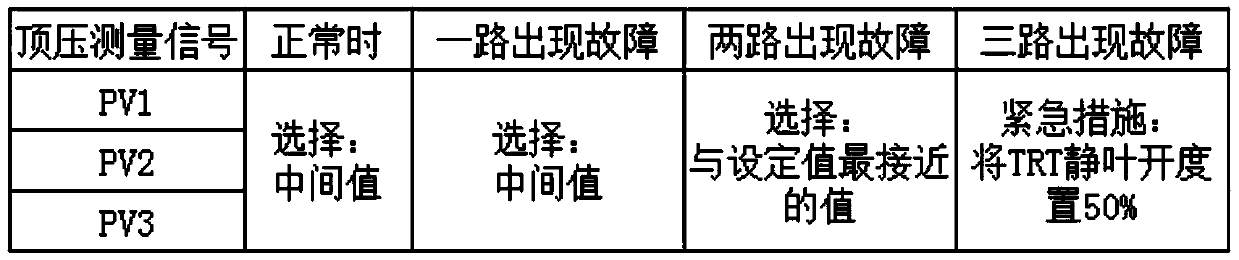

[0028] 3. Carry out program screening for the adoption of top pressure process value;

[0029] 4. Optimization of the connection signal between the blast furnace automatic control system and the BPRT unit automatic control system;

[0030] 5. Tak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com