Preparation method for baseboard of main pipe and sluice and step-style construction joint for side wall of flow channel layer

A step-type, bottom plate technology, applied in water conservancy projects, marine engineering, water conservancy engineering equipment and other directions, can solve the problems of easy cracks in the pier wall of the flow channel layer, general water-stop effect at construction joints, and difficulty in controlling the quality of construction joints, etc. Achieve the effect of solving the poor water stop effect, improving the management and control level and quality, and reducing the difficulty of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

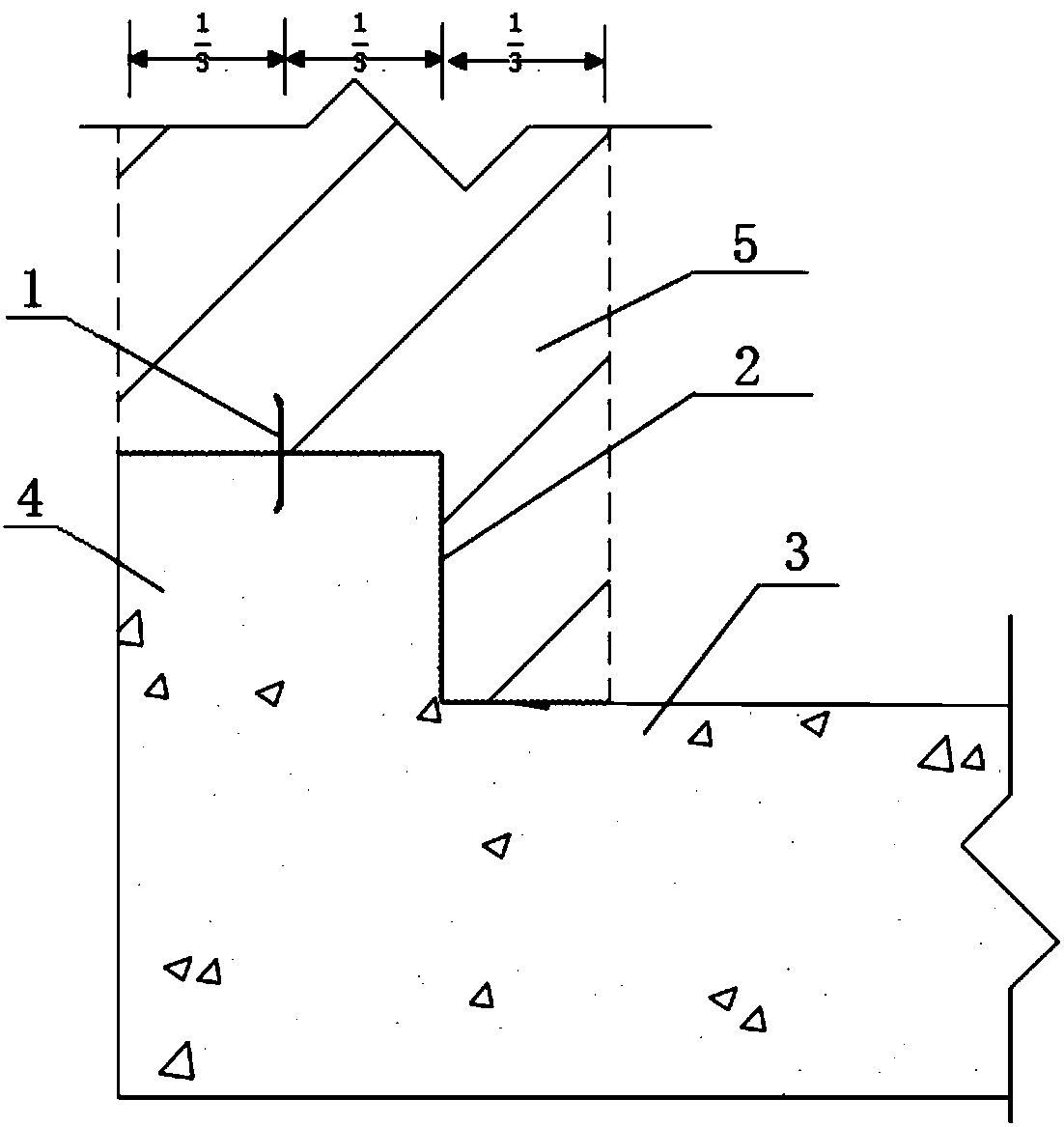

[0073] Embodiment 1: as attached figure 1 As shown, the construction method includes the following steps:

[0074] 1. Reinforcement engineering;

[0075] (1) Standing and binding of reinforcement bars on the base plate: positioning and setting out of reinforcement bars, binding of reinforcement bars at the bottom of the base plate, setting and fixing of stirrup bars, binding and fixing of reinforcement bars at the top layer of the base plate;

[0076] (2) Vertical reinforcement binding of the side wall of the runner: the vertical reinforcement of the side wall of the runner is erected and fixed, and the horizontal reinforcement within 1m of the lower part of the side wall of the runner is bound;

[0077] 2. Template engineering;

[0078] (1) Erection and reinforcement of base plate 3 formwork: base plate 3 formwork lofting, base plate 3 formwork processing, base plate 3 formwork erection, base plate 3 formwork reinforcement.

[0079] (2) Formwork erection and reinforcement ...

Embodiment 2

[0089] The project is a two-way diversion and drainage pumping station with a design flow rate of 60m 3 / s, using four 15m 3 / s two-way vertical shaft through-flow pump. The floor section of the standing body is 40m long, 30m wide, and 1.35m thick, and all the concrete is poured at one time. The runner is a special-shaped runner, and the concrete is poured using a combination of steel formwork and wood formwork.

[0090] The main function of the diversion pump gate in the reconstruction and expansion project of the pump gate of Diandong Water Conservancy Project is to divert water from Qingsong area to Dianbei area in one direction. The design flow rate of the diversion pumping station is 20m 3 / s, the design flow rate of the sluice emergency drainage is 58m 3 / s. The length of the main pump room is 24.6m, the width is 28.0m, the thickness of the side pier of the pump room is 1.2m, and the thickest part of the bottom plate is 1.6m.

[0091] The bottom plate of the standi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com