Spiral conveyor capable of automatically adjusting distance between blades and shell

A screw conveyor and automatic adjustment technology, which is applied in the direction of conveyors, conveyor objects, conveyor control devices, etc., can solve the problems of block materials or hard foreign objects mixed in, reducing the service life of equipment, and the rotation of spiral blades is blocked. Smooth, reduce the failure rate, the effect of small operating space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

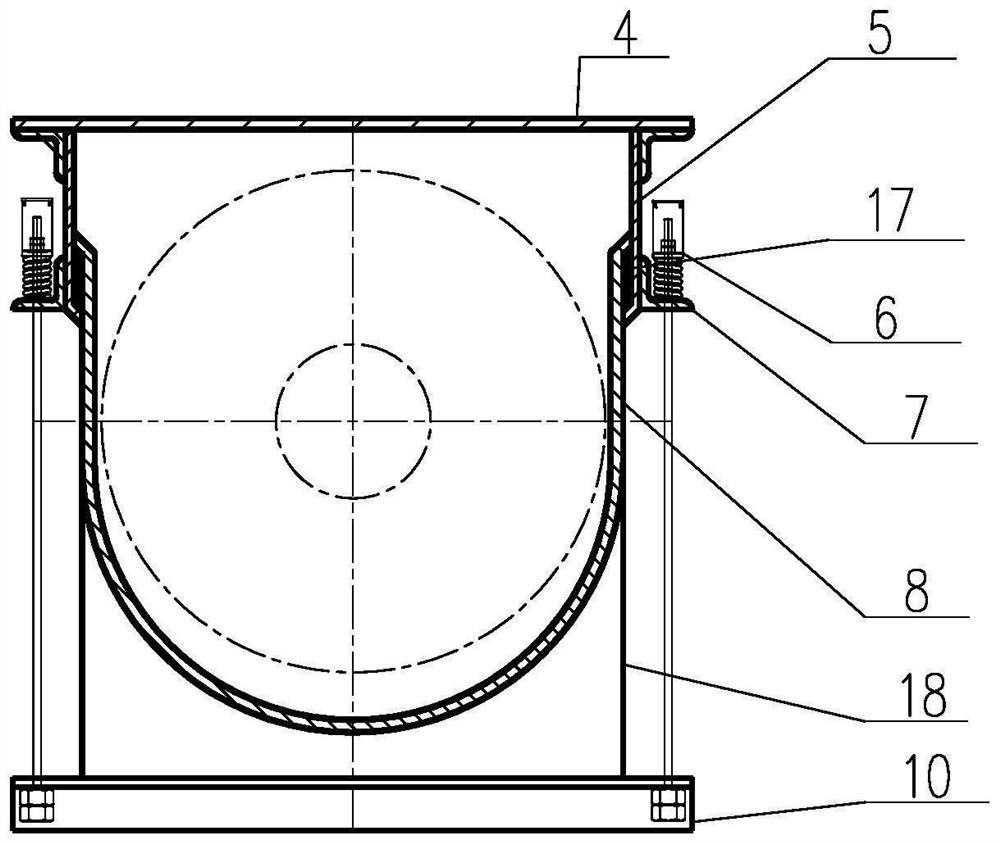

[0024] See Figure 1-Figure 3 As shown, the present invention relates to a screw conveyor that can automatically adjust the distance between the blade and the shell, including a head base 1, a head shell 2, a feed port 3, a cover plate 4, and an upper shell 5 , hydraulic locking device 6, angle steel (1) 7, lower shell 8, outrigger 9, angle steel (2) 10, spiral blade 11, tail shell 12, discharge port 14, speed monitoring sensor 15, transmission device 16 , sealing filler 17 and rib 18, the cover plate 4 and the upper casing 5 are fixed by bolt connection, the upper casing 5 and the lower casing 8 are slidingly connected, and a sealing filler 17 is arranged between them, and the head casing 2 and the tail housing 12 are respectively arranged at both ends and are respectively fixedly connected with the upper housing 5 and slidably connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com