Steel chair height numerical control cutting device and production method thereof

A cutting device and steel technology, applied in the direction of metal processing equipment, welding equipment, manufacturing tools, etc., can solve the problems of troublesome operation, low processing efficiency, uneven incision, etc., and achieve smooth incision, fast cutting speed and easy feeding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

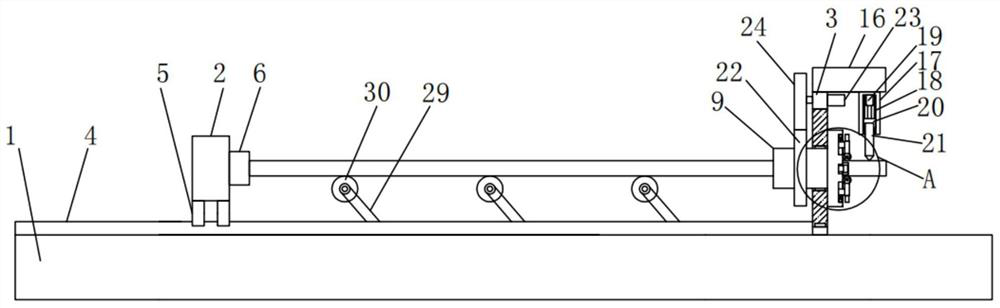

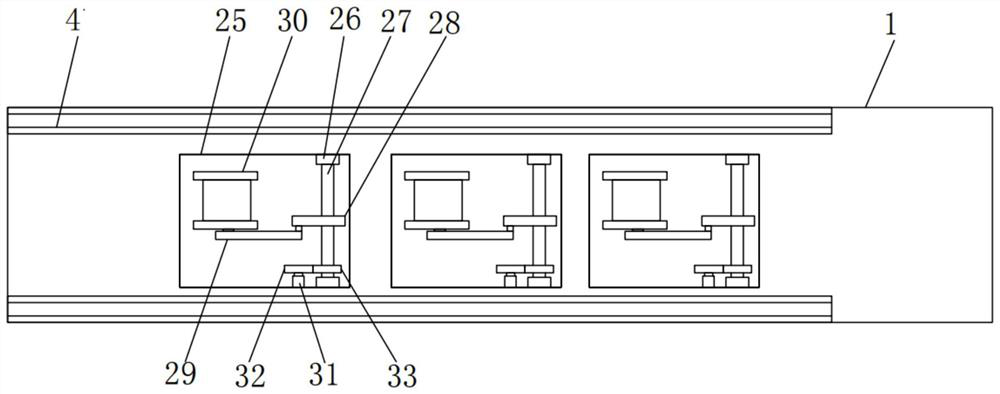

[0030] The present invention provides such Figure 1-4 A kind of steel chair-height CNC cutting device shown includes a workbench 1, a first support frame 2 and a second support frame 3, the top of the workbench 1 is symmetrically installed with slide rails 4 front and back, and the first The bottom of the support frame 2 is symmetrically provided with a slide seat 5 sliding on the front and rear slide rails 4, and the inside of the first support frame 2 is rotatably connected with a pneumatic chuck 6, and the sliding of the slide seat 5 on the slide rail 4 can drive The first support frame 2 moves to the left, and then realizes the automatic feeding work during cutting. The pneumatic chuck 6 belongs to the prior art, so its working principle will not be repeated here.

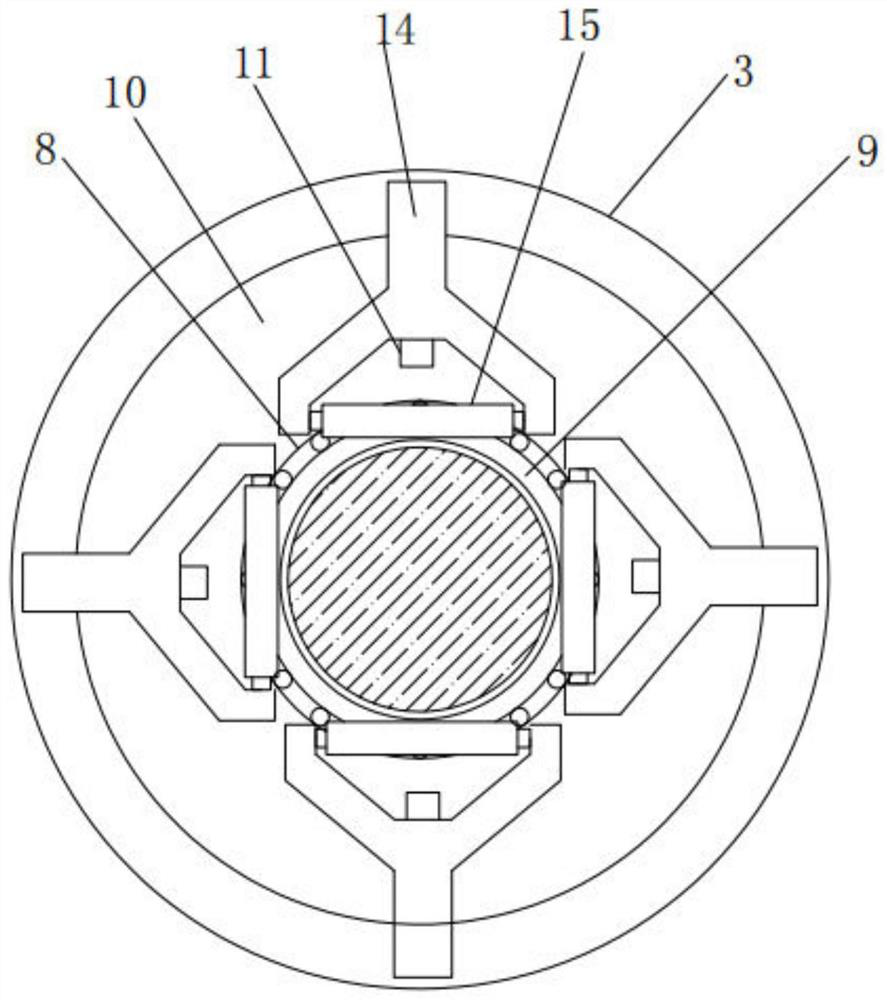

[0031] The middle part of the second support frame 3 is provided with a circular hole 7, and the center of the circular hole 7 coincides with the center of the pneumatic chuck 6. A bearing 8 is arranged in the...

specific Embodiment 2

[0037] A production method of a steel chair height numerical control cutting device, comprising the following steps:

[0038] Step 1: Use the pneumatic chuck 6 and four clamping shafts 10 to clamp the steel chair legs to be cut to ensure that the steel chair legs to be cut are firmly clamped;

[0039] Step 2: Start the first motor 23 to drive the first transmission gear 24 to rotate, so that the second transmission gear 22 meshed with it drives the hollow rotating shaft 9 to rotate, and realizes clamping between the pneumatic chuck 6 and the four clamping shafts 10 Rotational movement of the steel chair legs to be cut;

[0040] Step 3: According to the diameter of the steel chair leg to be cut, start the second cylinder 19 to drive its telescopic rod to extend, so that the laser cutting knife 21 can move to the surface of the steel chair leg to be cut, and realize the steel chair leg to be cut rotary laser cutting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com