Wearable jewelry based on SLM three-dimensional printing technology and preparation method thereof

A three-dimensional printing and jewelry technology, which is applied in the direction of cleaning methods using liquids, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of poor gloss and reflectiveness of jewelry, poor flexibility of jewelry, and overall quality reduction. , to achieve strong ornamental and artistic value, not easy to expand with heat and shrink with cold, and improve plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the above objects, features and advantages of the present invention more comprehensible, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

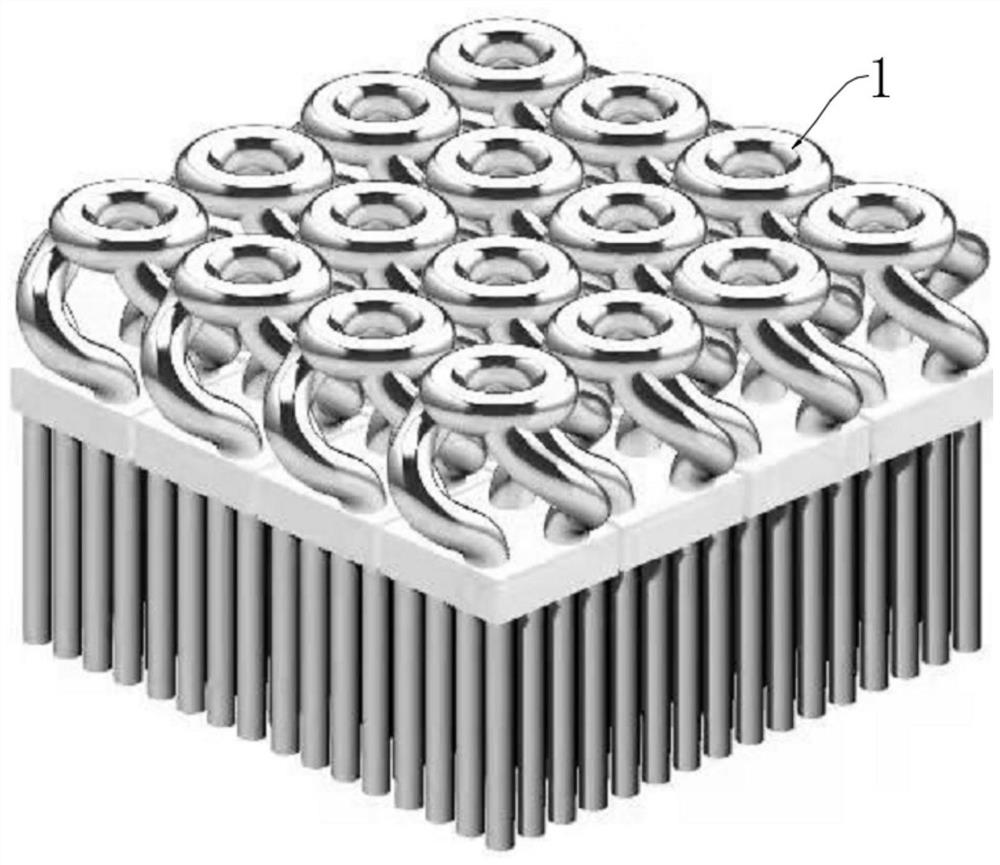

[0044] Such as Figure 1-9 As shown, this embodiment provides a wearable jewelry based on SLM three-dimensional printing technology, including a flexible active structure 1 and / or a lightweight lattice 2 .

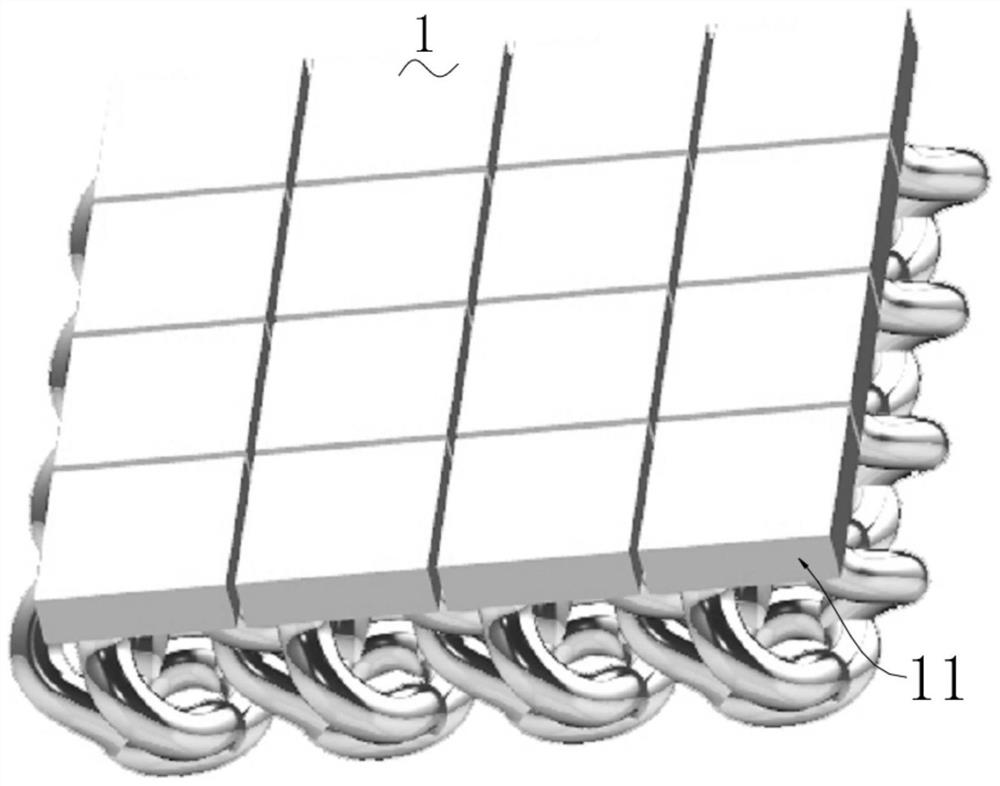

[0045] see image 3 , 4 As shown, one side of the flexible movable structure 1 is provided with a reflective surface, and the flexible movable structure 1 is formed by interlocking connection of first unit lattices 11;

[0046] see Figure 6 , 8 As shown, the lightweight lattice 2 is formed by the interlocking connection of the second unit lattices 21, every two adjacent second unit lattices 21 are mutually rotated by 45°, and all the second unit lattices 21 are topologically interlocked without forming a solid connection.

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com