Special fire extinguishing agent for sealed or semi-sealed space

A fire extinguishing agent, semi-sealing technology, applied in fire protection equipment and other directions, can solve problems such as difficulty in inhibiting the release of toxic gases, difficulty in storage and use, poor fire extinguishing effect, etc., and achieves good penetration ability, good fire extinguishing performance, and easy storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

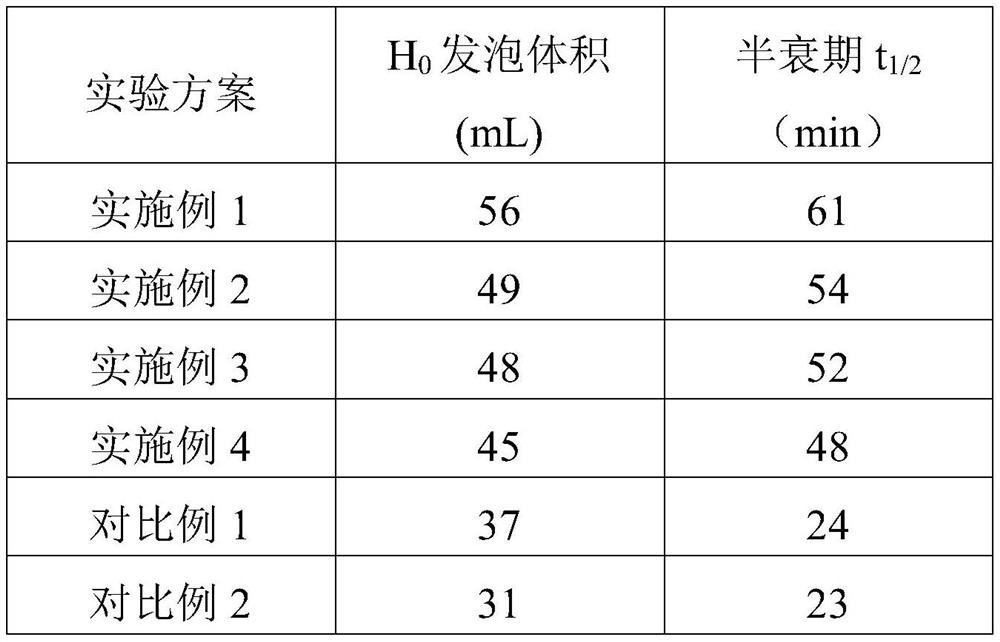

Examples

Embodiment 1

[0038] A preparation method of a special fire extinguishing agent for a sealed or semi-sealed space, comprising the following steps, and the parts are parts by weight:

[0039] Step 1. Mix 40 parts of water, 10 parts of zinc acetylacetonate and 2 parts of calcium carbonate evenly to prepare a mixed solution;

[0040] Step 2. Add 35 parts of inorganic composite gel solution, 15 parts of sodium bicarbonate and 5 parts of silicone oil to 52 parts of the mixed solution prepared in step 1, heat to 50°C, and use ultrasonic treatment with an ultrasonic frequency of 30kHz and an ultrasonic power of 900W , and the processing time is 60 minutes, that is, a special fire extinguishing agent for sealed or semi-sealed spaces is prepared.

[0041] The preparation method of the inorganic composite gel solution in the step 2 is as follows, and the parts are parts by weight:

[0042] S1. Add 40 parts of sodium α-olefin sulfonate, 20 parts of sodium alcohol ether sulfate and 5 parts of sodium c...

Embodiment 2

[0046] A method for preparing a special fire extinguishing agent for a sealed or semi-sealed space is basically the same as that of Example 1, the only difference being that the preparation method of the inorganic composite gel solution in the step 2 is inconsistent.

[0047] The preparation method of the inorganic composite gel solution in the step 2 is as follows, and the parts are parts by weight:

[0048] S1. Add 40 parts of sodium α-olefin sulfonate, 20 parts of sodium alcohol ether sulfate and 5 parts of sodium citrate to 400 parts of water to prepare a cross-linking agent solution, then add 6 parts of sodium hydroxide to the cross-linking agent solution, and stir well , to prepare a buffer solution;

[0049] S2. Add 9 parts of sodium trimetaphosphate to the buffer solution prepared in step S1, stir for 30 minutes, and the stirring speed is 300r / min; then let the solution stand for 30 minutes; then add 20 parts of glucomannan, and put the solution in a water bath at 45°C...

Embodiment 3

[0052] A method for preparing a special fire extinguishing agent for a sealed or semi-sealed space is basically the same as that of Example 1, the only difference being that the preparation method of the inorganic composite gel solution in the step 2 is inconsistent.

[0053] The preparation method of the inorganic composite gel solution in the step 2 is as follows, and the parts are parts by weight:

[0054] S1. Add 40 parts of sodium α-olefin sulfonate, 20 parts of sodium alcohol ether sulfate and 5 parts of sodium citrate to 400 parts of water to prepare a cross-linking agent solution, then add 6 parts of sodium hydroxide to the cross-linking agent solution, and stir well , to prepare a buffer solution;

[0055] S2. Add 9 parts of sodium trimetaphosphate to the buffer solution prepared in step S1, stir for 30 minutes, and the stirring speed is 300r / min; then let the solution stand for 30 minutes, add 30 parts of pentafluoropropane into the solution, stir for 10 minutes, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com