Konjac glucomannan targeted delivery capsule and preparation method thereof

A konjac glucomannan, targeting technology, applied in microcapsules, capsule delivery, pharmaceutical formulations, etc., can solve the problem of low drug loading, achieve the effects of improving the release amount, the preparation method is convenient and fast, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

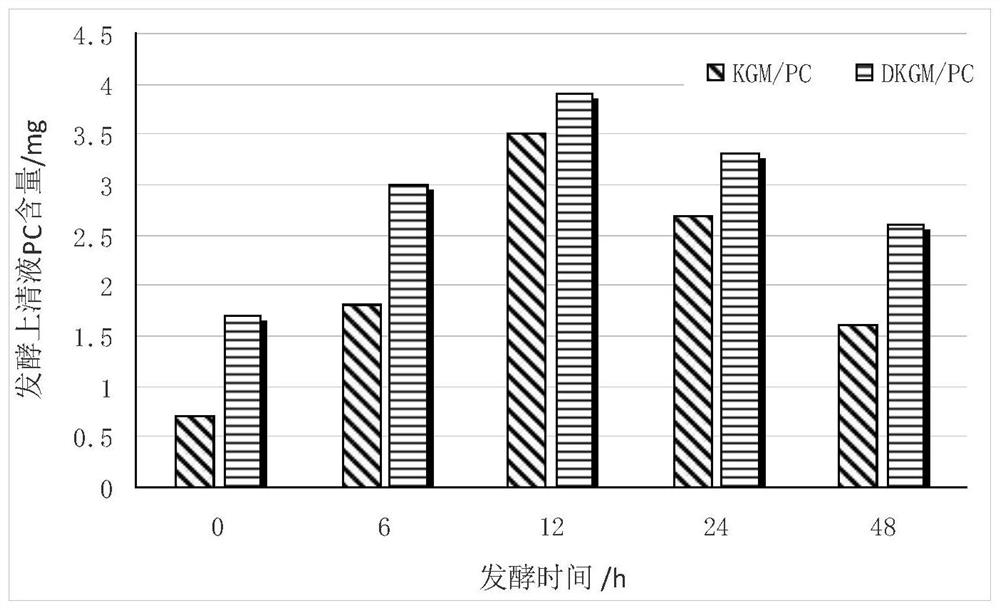

Image

Examples

preparation example Construction

[0031] The invention provides a method for preparing konjac glucomannan targeted delivery capsules, comprising the following steps:

[0032] S1. Preparation of DKGM powder: Mix KGM powder with an ethanol solution with a volume concentration of 25-50%, stir and react at 20-70°C for 5-10min, add lye, and continue to stir and react at 20-70°C for 10-10min After 20 minutes, the DKGM crude product was obtained; the DKGM crude product was washed and dried to obtain DKGM powder;

[0033] S2. Preparation of DKGM / active ingredient microcapsules: Dissolve the water-soluble active ingredient in pure water to obtain an active ingredient solution, add the DKGM powder in step S1 to the active ingredient solution, stir for more than 15 minutes, centrifuge, and take the precipitate, DKGM / active ingredient microcapsules were obtained after vacuum freeze-drying.

[0034] In step S1, alkali lye is sodium hydroxide solution, and the ratio of the quality of KGM powder and the molar number of alka...

Embodiment 1

[0046] A konjac glucomannan targeted delivery capsule, the preparation method of which comprises the following steps:

[0047] S1. Preparation of DKGM powder: Put 3.0 g of KGM powder into a beaker with stirring, add 100 mL of ethanol solution with a volume concentration of 30% into the beaker, put the beaker into a microwave reactor, turn on the microwave reactor, and control the reaction temperature 50°C, stirred for 5 minutes, and the stirring speed was 150rpm. Then, 10 mL of NaOH solution with a concentration of 0.2 mol / mL was added to the beaker, the reaction temperature was controlled at 50 ° C under microwave heating conditions, and the reaction was continued to stir for 10 min at a stirring speed of 150 rpm to obtain crude DKGM. After the reaction, the DKGM crude product is gradiently washed with ethanol solutions with a volume concentration of 30%, 60% and 90%, respectively, so as to wash away excess alkali, and then dehydrated with absolute ethanol to obtain a DKGM se...

Embodiment 2~ Embodiment 6

[0050] The differences between Embodiment 2 to Embodiment 6 and Embodiment 1 are shown in Table 1.

[0051] Table 1 The process parameter table of each embodiment

[0052]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com