Method for solving false alarm problem of float-type oil level sensor

A fuel level sensor and float type technology, which is applied in the field of aerospace aircraft fuel measurement, can solve problems such as unfavorable flight safety, achieve the effect of solving false alarm problems, meeting the use requirements, and realizing software debounce

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

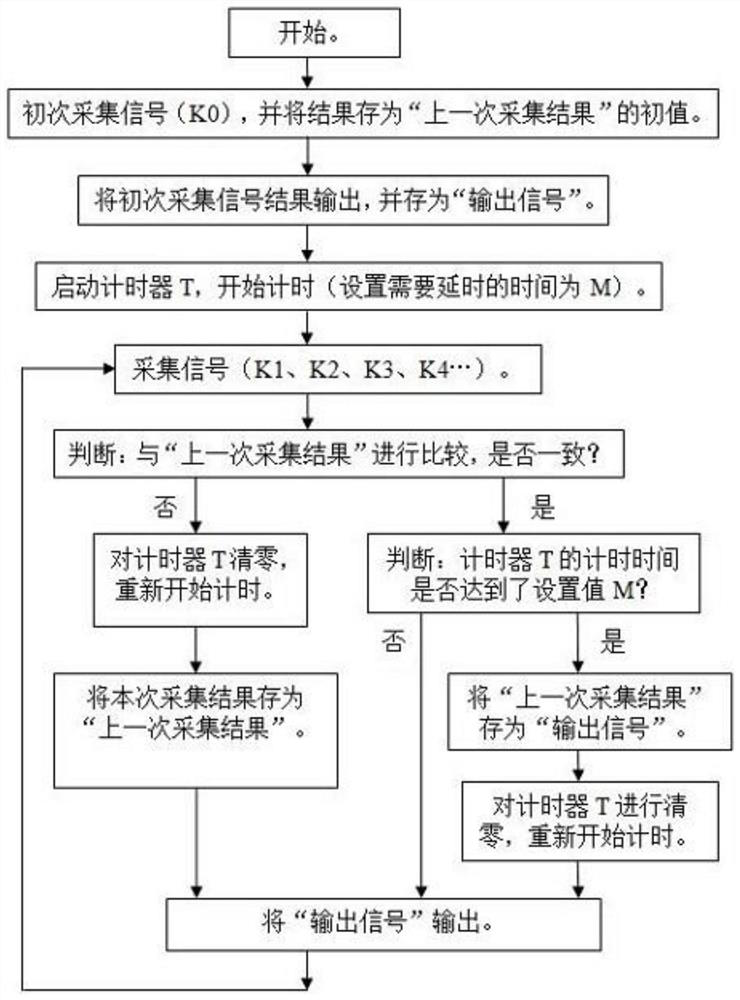

[0033] This embodiment proposes a method for solving the false alarm of the float type oil level sensor, which specifically includes the following steps:

[0034] Step 1: Collect the first oil level signal data of the float type oil level sensor;

[0035] Step 2: Save the oil level signal data collected for the first time as the "last collection result" and use it as the "output signal", and then start the timer T for timing;

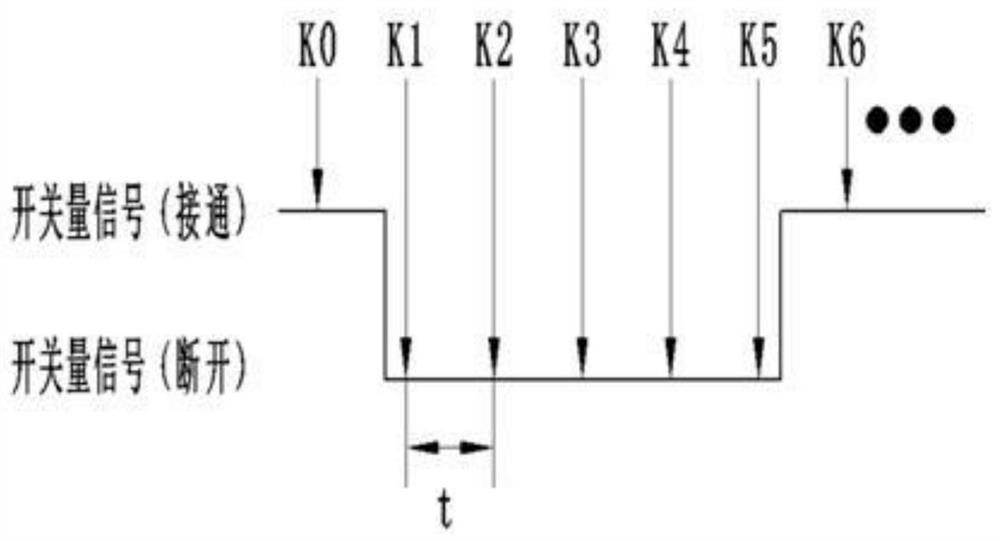

[0036] Step 3: every time the timer T counts once, a follow-up oil level signal data acquisition is performed; the signal acquisition time interval between each oil level signal data acquisition is t; in the subsequent oil level signal data acquisition process In , compare the oil level signal data collected this time as the "result of this collection" with the "result of the previous collection":

[0037] When the "collection result of this time" is inconsistent with the "result of the previous collection", the timer T is reset, and the timing is rest...

Embodiment 2

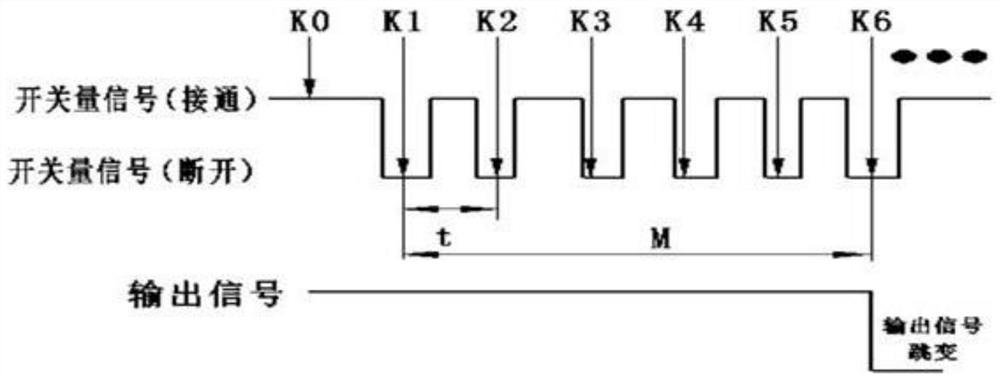

[0040] In this embodiment, on the basis of the above-mentioned embodiment 1, in order to better realize the present invention, further, in the step 2, a delay time M is set for the timer T;

[0041] In step 3, when the "current collection result" is consistent with the "last collection result":

[0042] If the timing time of the timer T reaches the delay time M, the "last collection result" is stored as an "output signal" and output;

[0043] If the timing time of the timer T does not reach the delay time M, the timer T continues timing and keeps the "output signal" unchanged.

[0044] Other parts of this embodiment are the same as those of Embodiment 1 above, so details are not repeated here.

Embodiment 3

[0046] In this embodiment, on the basis of any one of the above-mentioned embodiments 1-2, in order to better realize the present invention, further, calculate the minimum holding time y and the maximum holding time of the on / off of the signal sent by the float type oil level sensor time z;

[0047] The delay time M is greater than the maximum holding time z.

[0048] Other parts of this embodiment are the same as those of any one of Embodiments 1-2 above, so details are not repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com