Radiation-resistant PP electret melt-blown material and preparation process thereof

A radiation-resistant and electret technology, which is applied in the manufacture of rayon, conjugated synthetic polymer rayon, and fiber chemical characteristics, can solve the problem of low filtration efficiency, low strength, and strong smell of melt-blown cloth. and other issues, to achieve the effect of safe and reliable production process, stable product quality and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

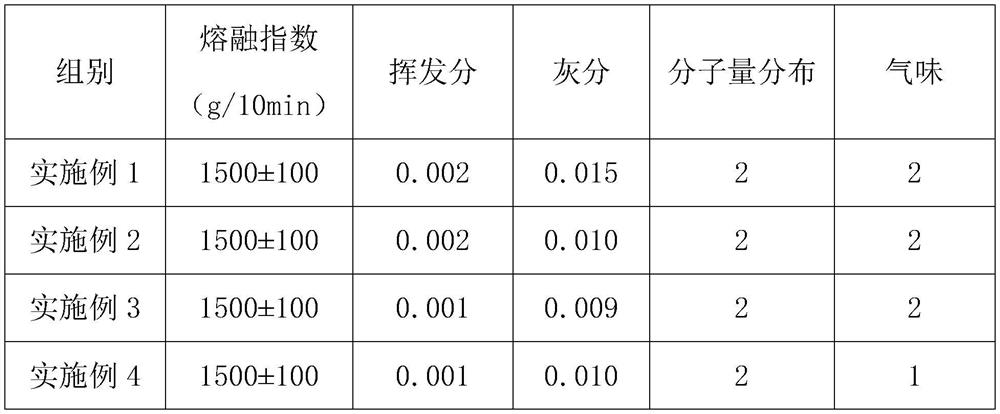

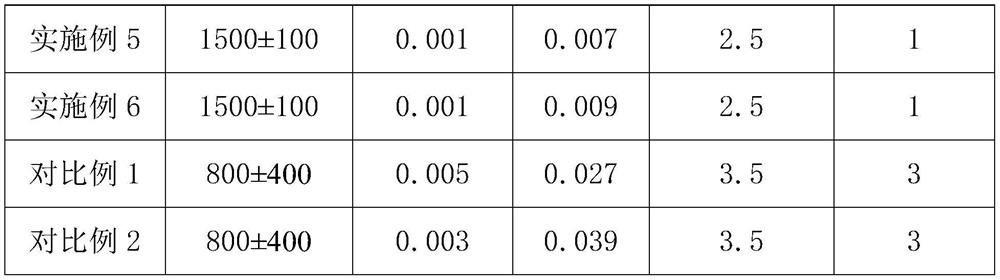

Examples

Embodiment 1

[0027] This embodiment discloses a preparation process of radiation-resistant PP electret melt-blown material, which specifically includes the following steps:

[0028] Step 1. Stir and mix 50 parts of modified nano-silica, 10 parts of modified nano-silica and 1 part of electret agent under heating conditions, then raise the temperature to 200-220 °C, and then add homopolypropylene resin 50 parts and 1 part of accelerator Tac are mixed evenly and sent to a twin-screw extruder, melted and mixed, extruded, wind-cut and dried to obtain electret masterbatch.

[0029] Among them, the preparation method of the modified nano-silica is as follows: put the nano-silica particles into an electrothermal constant-temperature blast drying oven, dry at 80°C for 5 hours, and then put them into a tank containing a mixture of absolute ethanol and deionized water. In a beaker, ultrasonically disperse for 30 minutes, add a silane coupling agent and stir evenly, adjust the pH to 4-5 with acetic ac...

Embodiment 2

[0041] This example is basically the same as the preparation process disclosed in Example 1, except that the electret masterbatch includes the following components in parts by weight: 65 parts of homopolypropylene resin, 12.5 parts of modified nano-silica, modified 15 parts of permanent nano-silica, 3 parts of accelerator Tac, and 5 parts of electret agent.

Embodiment 3

[0043] This example is basically the same as the preparation process disclosed in Example 1, except that the electret masterbatch includes the following components in parts by weight: 80 parts of homopolypropylene resin, 15 parts of modified nano-silica, modified 18 parts of permanent nano-silica, 5 parts of accelerator Tac, and 9 parts of electret agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com