Welding bogie for rail engineering vehicle

A technology for rail engineering vehicles and bogies, which is applied in the direction of the bogies, devices for lateral relative movement between the chassis and the bogies, railway car body parts, etc. Adapt to the environmental protection requirements of urban rail transit, and cannot meet the problems of loading cargo weight, etc., to achieve the effect of improving lateral stability and operating stability, improving vertical dynamic performance, and improving stability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

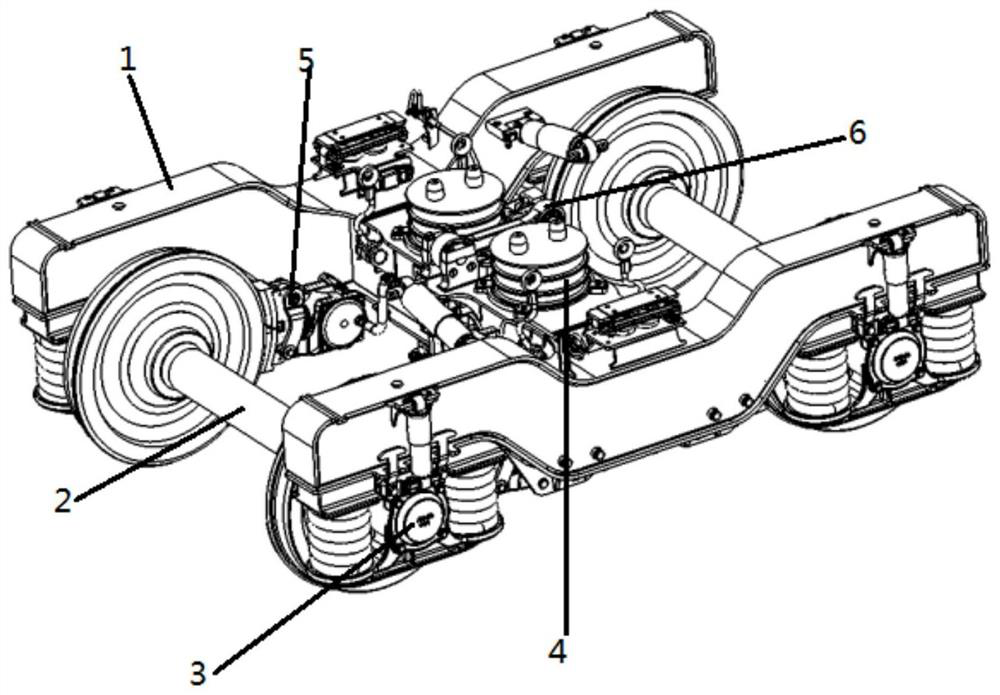

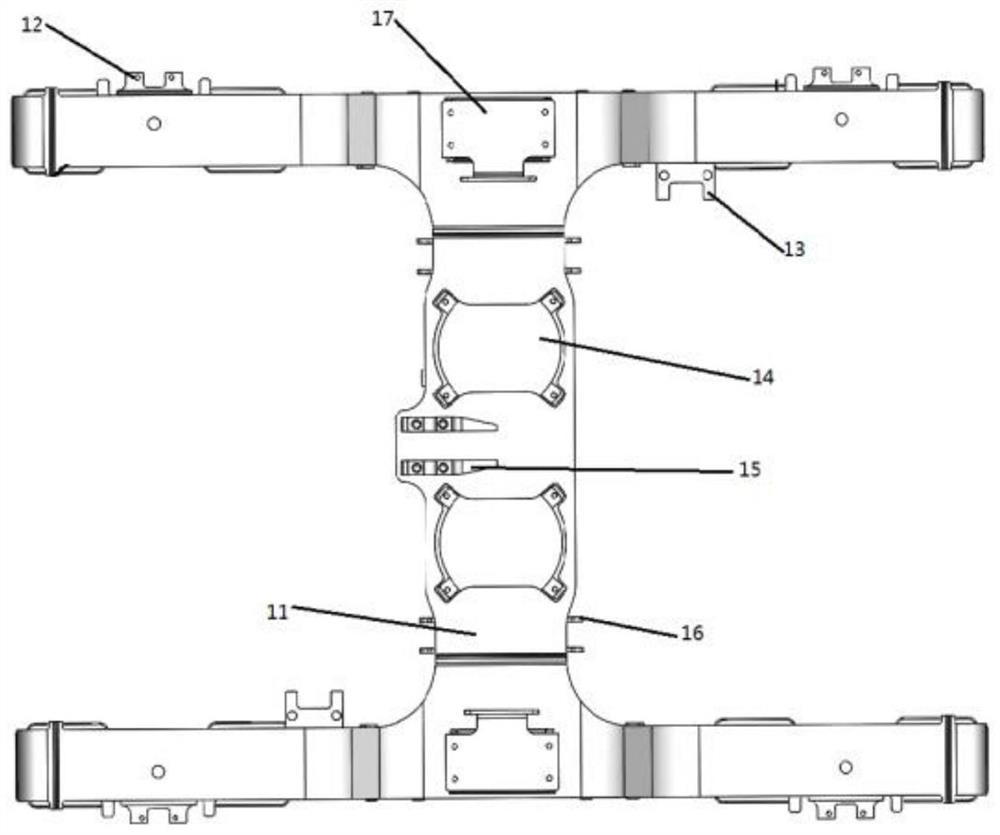

[0023] Such as Figure 1-Figure 7 As shown, the present invention provides a kind of welding bogie for railway engineering vehicles, comprising frame composition 1, wheelset composition 2, axle box suspension device 3, secondary suspension device 4, braking device 5 and traction device 6, described Frame composition 1 is an H-shaped structure formed by welding and splicing side beams 7 and cross beams 11. The side beam 7 is a U-shaped structure, which can lower the center of gravity of the vehicle and improve running stability and safety. Diamond-shaped deformation, strong anti-rhombic ability, meeting the requirements of strength and rigidity; side beam 7 is welded with side bearing seat 17, transverse shock absorber seat 13 and vertical shock absorber seat 12, and cross beam 11 is welded with rubber pile seat 14 , traction seat 15 and anti-jump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com