Robot automatic feeding and discharging sub-control system for production auxiliary equipment of flexible machining production line

A technology of automatic loading and unloading, production assistance, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of product uncertainty, lack of versatility, single gripper, etc., to meet the effect of flexible production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Next, the technical solutions in the embodiments of the present invention will be clear and complete, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. It does not constitute a limit to the present invention. Based on the embodiments of the invention, all other embodiments obtained without making creative labor premises, in the preceding embodiments of the present invention.

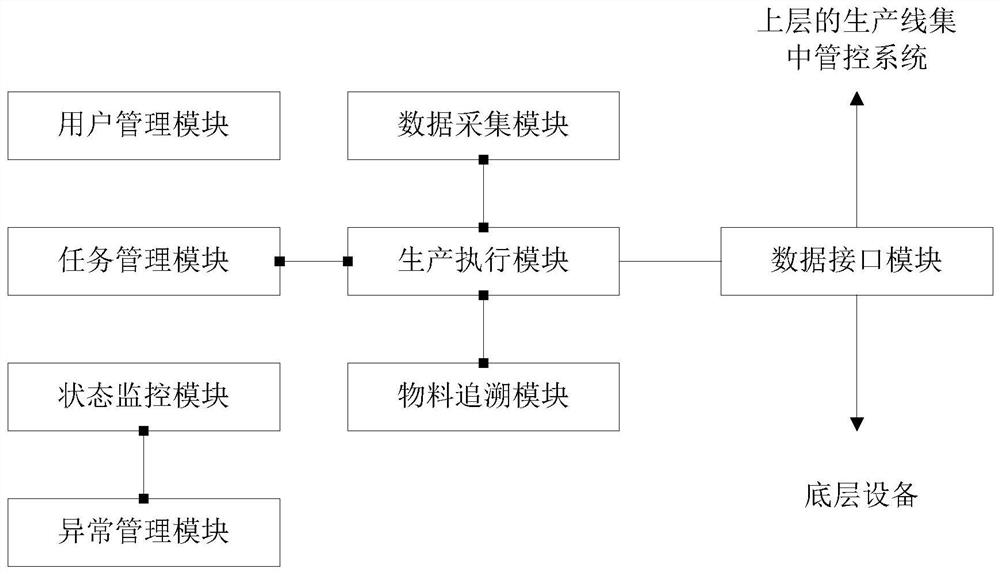

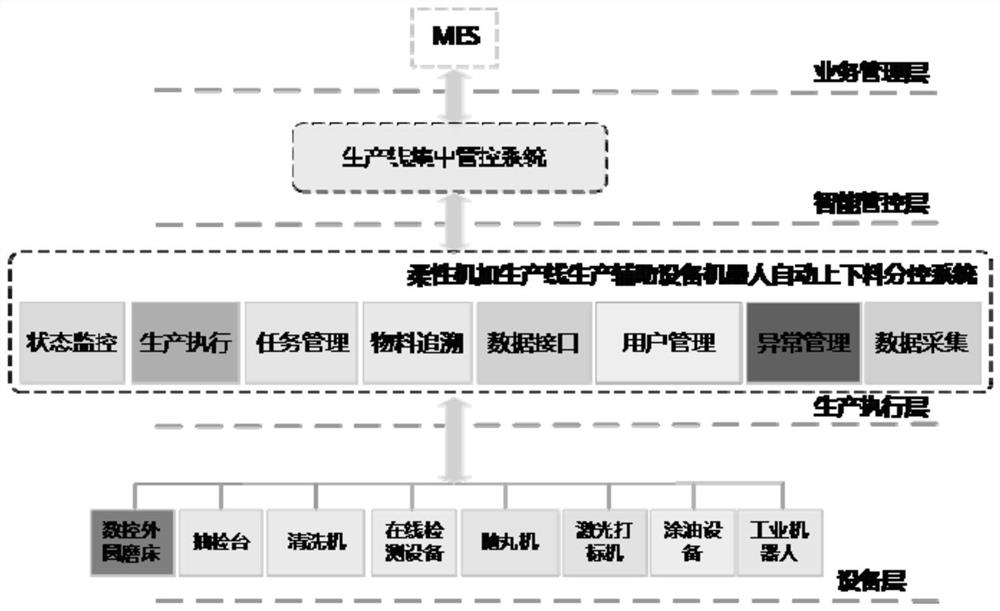

[0025] like figure 1 The schematic diagram of the robotic automatic upper and lower material control system for the production of the flexible machine plus production line according to the embodiment of the present invention, the control system mainly includes a state monitoring module, a production execution module, a task management module, a material traceability module, Data interface module, user management module, exception management module, data acquisition module, where:

[0026] The status monitoring module is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com