Cosmetic film-forming composition with lotus leaf effect

A composition and cosmetic technology, applied in the field of cosmetic film-forming compositions, can solve the problem that the anti-pollution effect cannot be achieved, the application of polymethylsilsesquioxane and silylated silica has not yet been found, and the air permeability and moisture permeability Weak and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

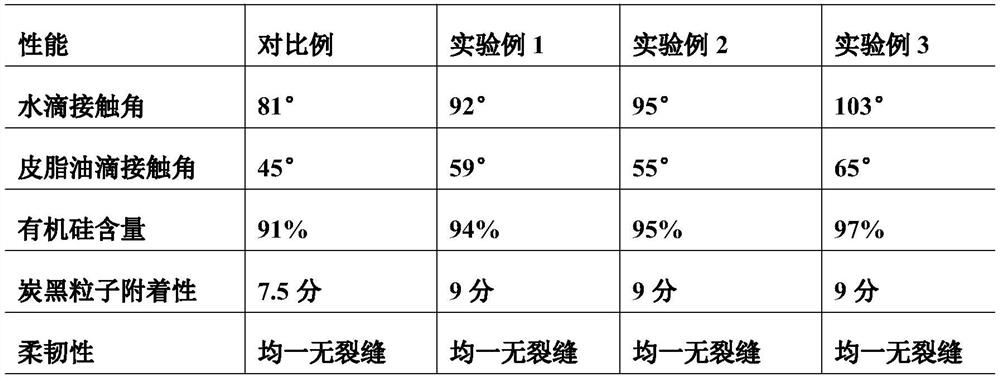

Examples

Embodiment 1

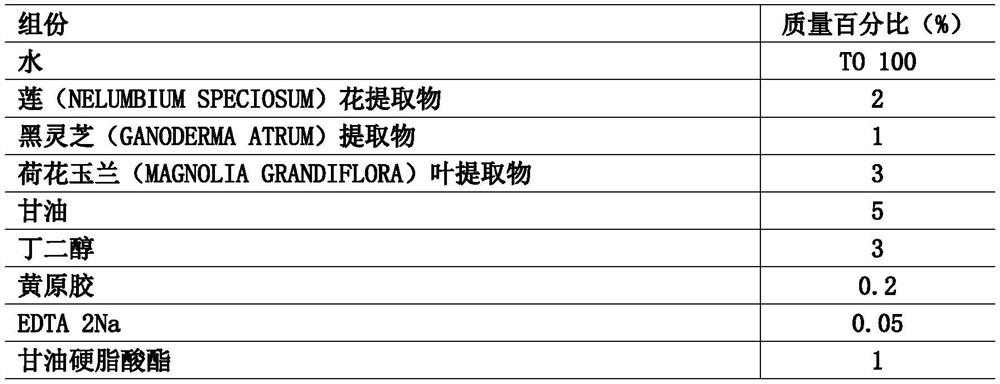

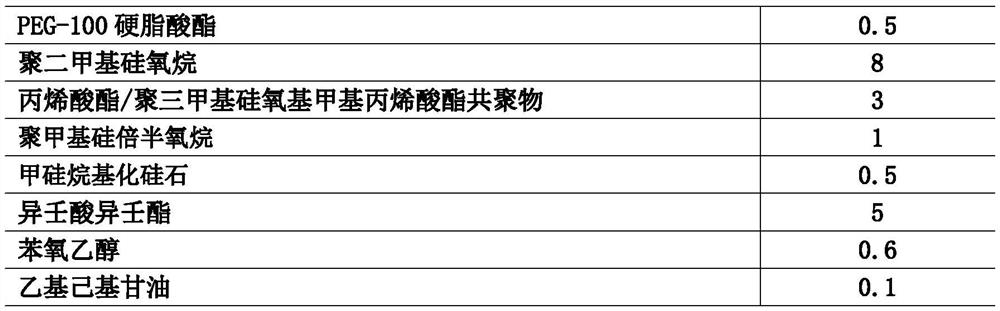

[0025] A kind of film-forming composition for cosmetics with lotus leaf effect, said film-forming composition comprises acrylic acid (ester) type / polytrimethicone methacrylate copolymer, polydimethylsiloxane and polymethicone Methylsilsesquioxane, wherein the mass ratio of acrylic acid (esters) / polytrimethylsiloxane methacrylate copolymer to polymethylsilsesquioxane is (10-35): (1- 10).

[0026] The polymethylsilsesquioxane adopts micron-order regular spherical powder with an average particle diameter of 2.0-8.0um. The viscosity of the polydimethylsiloxane is 6cs.

[0027] The preparation method of above-mentioned film-forming composition comprises the following steps:

[0028] a. Disperse acrylic (ester) / polytrimethylsiloxane methacrylate copolymer in polydimethylsiloxane, heat up at a rate of 0.5-1°C / min, heat to 45°C, and keep warm After 10-15 minutes, the Primix homogenizer was used to disperse at a low speed of 1500rpm for 15-30 minutes to form a uniform transparent li...

Embodiment 2

[0031] A film-forming composition for cosmetics with a lotus leaf effect, the film-forming composition comprises acrylic acid (esters) / polytrimethicone methacrylate copolymer, polydimethylsiloxane and methacrylic acid Silylated silica, wherein the mass ratio of acrylic acid (ester) / polytrimethylsiloxane methacrylate copolymer to silylated silica is (10-35):(0.5-5).

[0032] The silica silylate adopts nano-scale hemispherical powder.

[0033] The viscosity of the polydimethylsiloxane is 6cs.

[0034] The preparation method of above-mentioned film-forming composition comprises the following steps:

[0035] a. Disperse acrylic (ester) / polytrimethylsiloxane methacrylate copolymer in polydimethylsiloxane, heat up at a rate of 0.5-1°C / min, heat to 45°C, and keep warm After 10-15 minutes, the Primix homogenizer was used to disperse at a low speed of 1500rpm for 15-30 minutes to form a uniform transparent liquid and obtain phase A.

[0036] b. Slowly add silica silylate into phase ...

Embodiment 3

[0038] A kind of cosmetic film-forming composition with lotus leaf effect, described film-forming composition comprises acrylic acid (ester) type / polytrimethylsiloxane methacrylate copolymer, polymethylsilsesquioxane and Silica silylate, wherein the mass ratio of acrylic acid (ester) / polytrimethylsiloxane methacrylate copolymer, polymethylsilsesquioxane to silica silylate is (10-35) :(1-10):(0.5-5).

[0039] The polymethylsilsesquioxane adopts micron-order regular spherical powder with an average particle diameter of 2.0-8.0um.

[0040] The silica silylate adopts nano-scale hemispherical powder.

[0041] The viscosity of the polydimethylsiloxane is 6cs.

[0042] The preparation method of above-mentioned film-forming composition comprises the following steps:

[0043] a. Disperse acrylic (ester) / polytrimethylsiloxane methacrylate copolymer in polydimethylsiloxane, heat up at a rate of 0.5-1°C / min, heat to 45°C, and keep warm After 10-15 minutes, the Primix homogenizer was use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com