Porous ceramic heating body and atomizer

A technology of porous ceramics and heating element, applied in the field of atomizers, can solve the problems of falling off of heating components, increasing the amount of e-liquid, poor bonding strength, etc., and achieve the effects of increasing heating efficiency, safe and environmentally friendly service life, and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

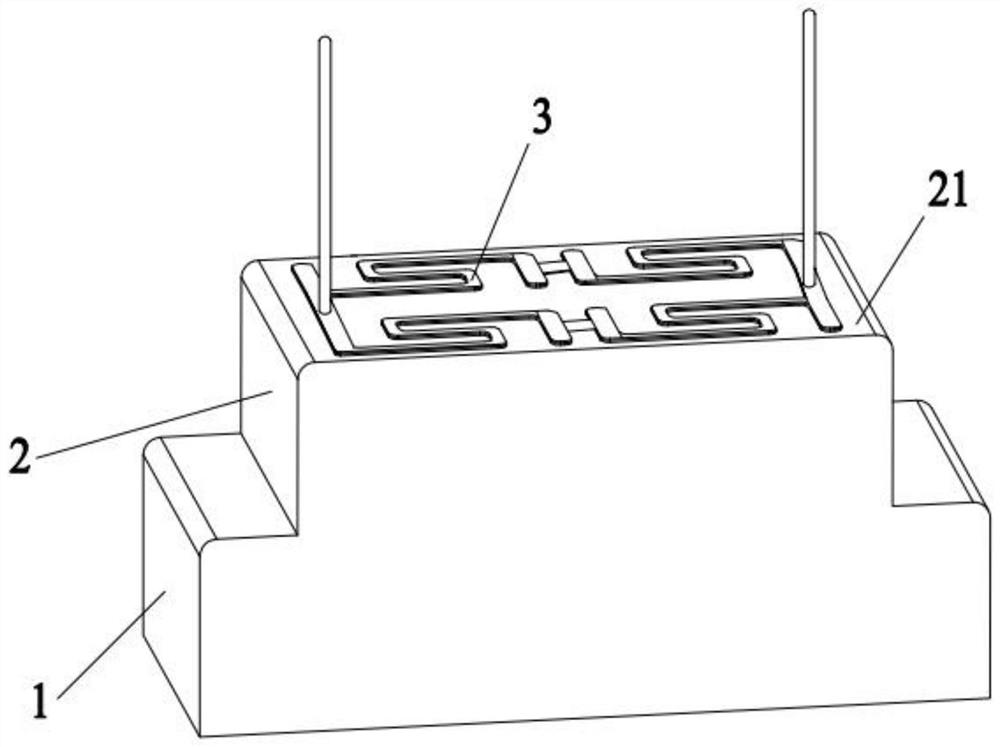

[0032] A porous ceramic heating element comprising a porous ceramic matrix, said ceramic matrix comprising a porous substrate and a reservoir substrate atomizing 12, the oil reservoir is provided on a base surface of the base body 2 is atomized, the oil reservoir surface of the base body 1 is the oil guide surface 11, the oil guide surface 11 is provided with a plurality of recessed sump 12, the lower surface of the base 2 of the atomizing surface 21 for atomization, the atomization surface 21 with a plurality of heat generating printed assembly 3, the position corresponding to the heat generating component 3 disposed in the sump 12, the sump 12 for placing the heat generating components 3, the reservoir 2 using a porous ceramic material and the base body 1 is integrally sintering atomized matrix . The sump 12 is provided at least two groups; the two are connected in parallel between the adjacent heat generating components 3.

[0033] The heat generating assembly 3 includes a heati...

Embodiment 2

[0045] A porous ceramic heat generating body comprising a porous ceramic substrate comprising an oil substrate 1 and an atomizing base 2, the oil storage base 1 is disposed on the upper surface of the atomizing base 2, the oil. The upper surface of the substrate 1 is a conducting surface 11, and the oil surface 11 is concave, and the lower surface of the atomization surface 21 is concave, and the atomization surface 21 is buried with several fever. As a member 3, the heat generating assembly 3 corresponds to the position of the oil storage tank 12, and the oil collecting base 1 and the atomization base 2 are integrally sintered with a porous ceramic material. The oil storage tank 12 is provided at least two groups; a connection between the two of the heat generating assemblies 3.

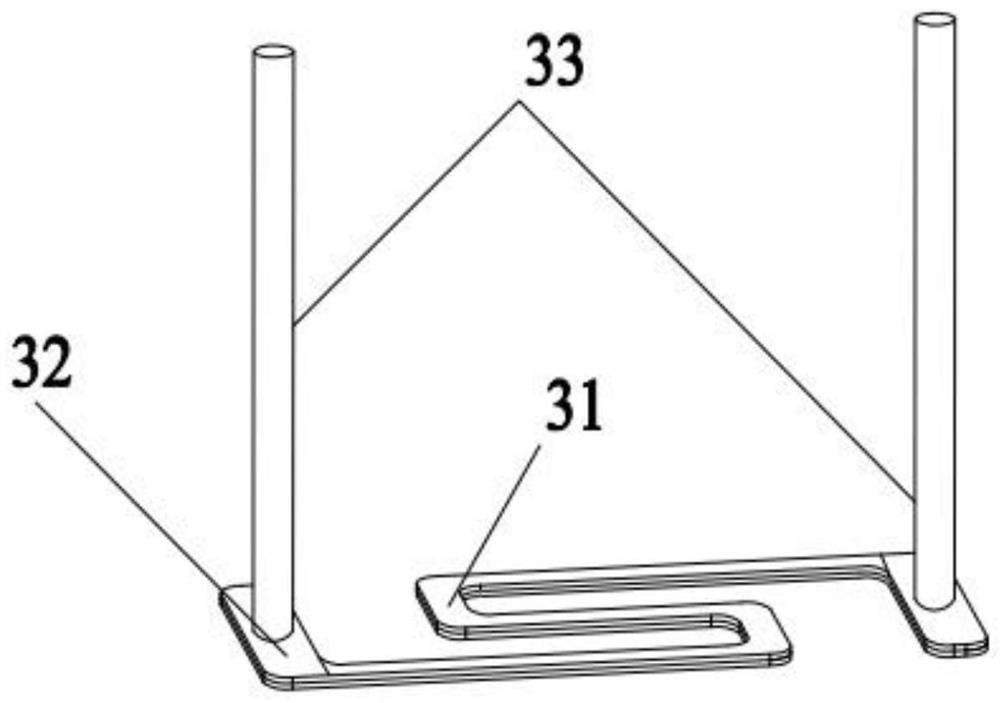

[0046] The heat generating assembly 3 includes a heating line 31, two resistive sheets 32, and two terminals 33, which are respectively connected to both ends of the heating line 31, respectively, respe...

Embodiment 3

[0058] A porous ceramic heat generating body comprising a porous ceramic substrate comprising an oil substrate 1 and an atomizing base 2, the oil storage base 1 is disposed on the upper surface of the atomizing base 2, the oil. The upper surface of the base body 1 is a conductive surface 11, and the oil surface 11 is concave, and the lower surface of the atomizing substrate 2 is atomized surface 21, and the atomization surface 21 is printed with several fever. As a member 3, the heat generating assembly 3 corresponds to the position of the oil storage tank 12, and the oil collecting base 1 and the atomization base 2 are integrally sintered with a porous ceramic material. The oil storage tank 12 is provided at least two groups; a connection between the two of the heat generating assemblies 3.

[0059] The heat generating assembly 3 includes a heating line 31, two resistive sheets 32, and two terminals 33, which are respectively connected to both ends of the heating line 31, respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com