Friction-electromagnetic composite power generation device and performance test platform and method thereof

A power generation device and composite technology, which is applied in the direction of motor generator testing, friction generator, synchronous motor with stationary armature and rotating magnet, etc., can solve the problem of low conversion efficiency of power generation energy, inability to efficiently collect electromagnetic generators, etc. problem, to achieve the effect of improving energy conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

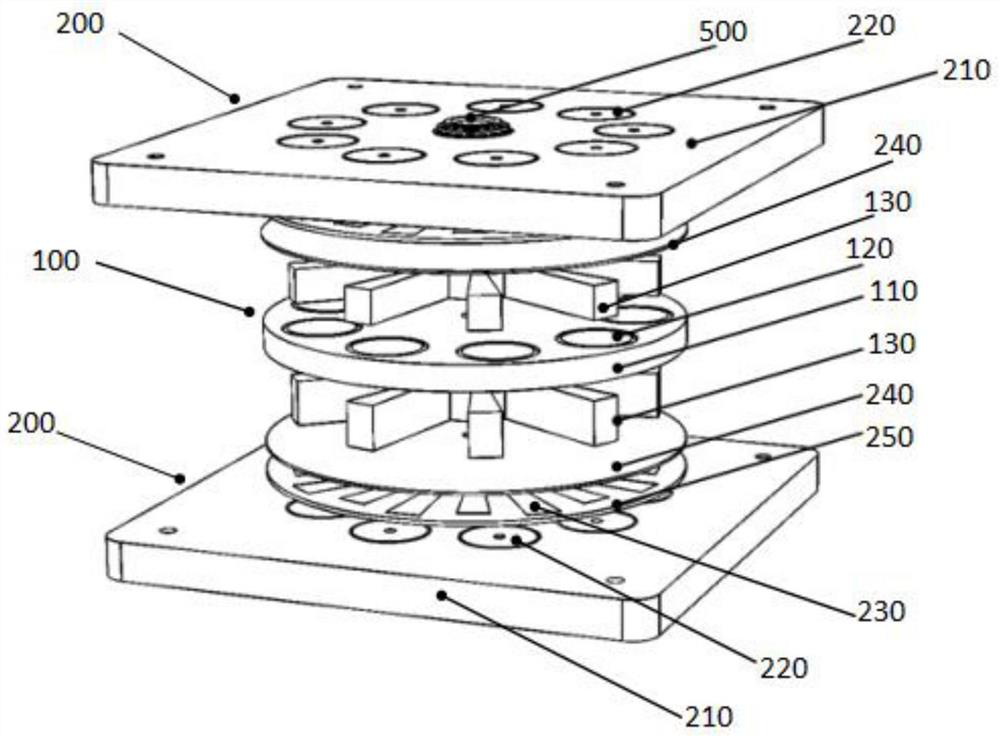

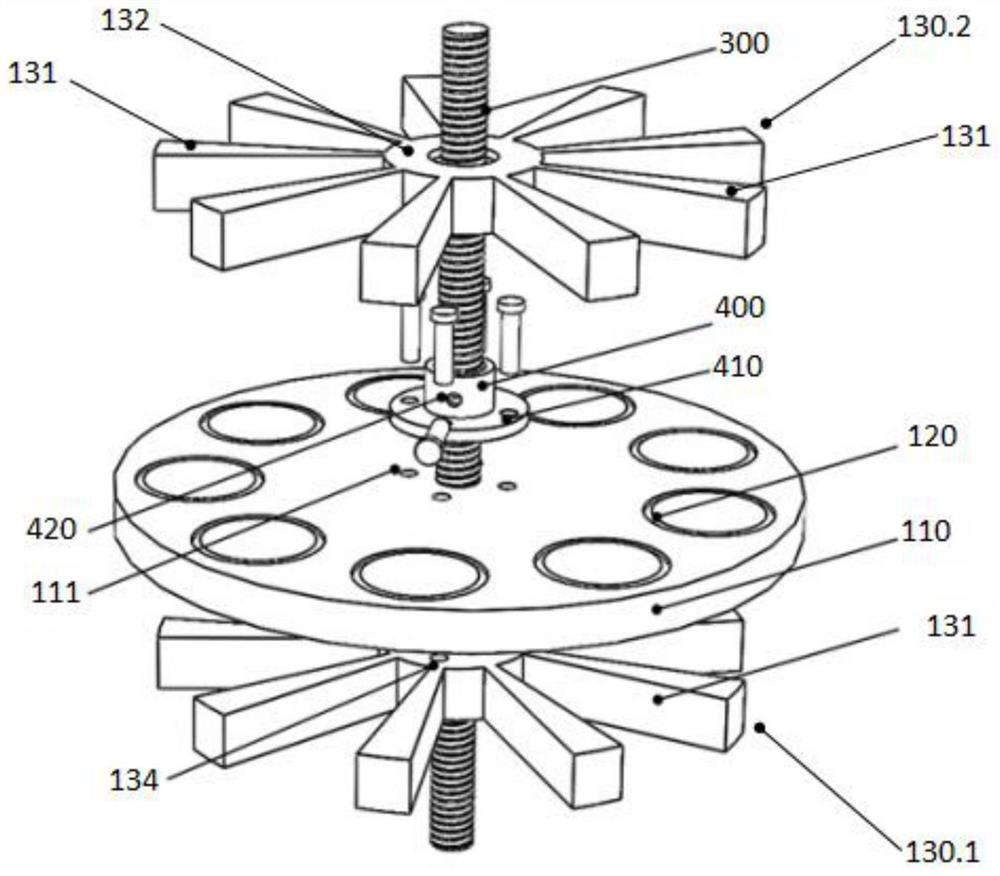

[0074] See Figure 1 to 4 , figure 1 A friction-electromagnetic composite type power generating device provided by the embodiment of the present invention.

[0075] A friction-electromagnetic composite generating device provided by the present invention, including:

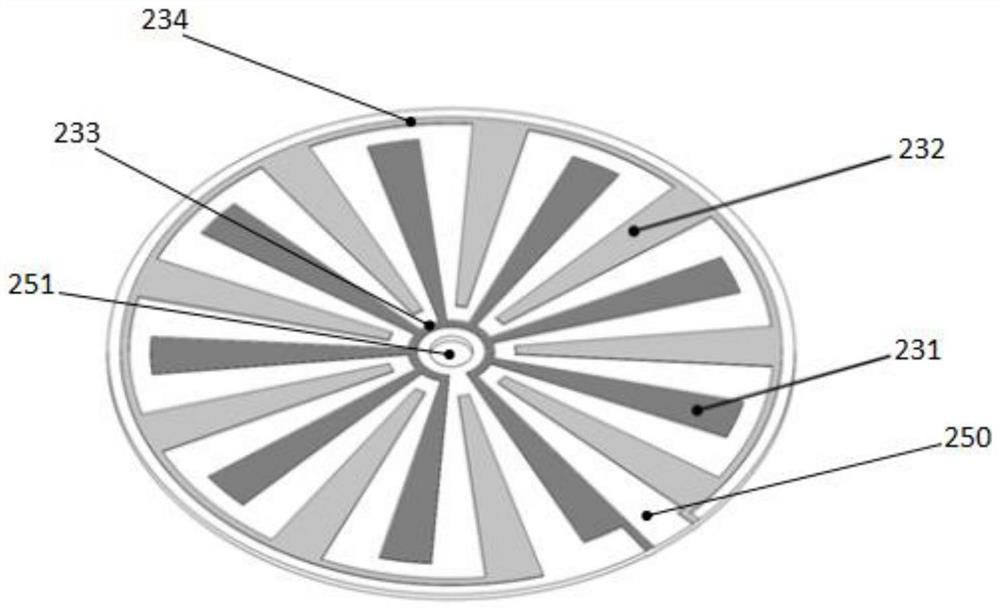

[0076] The rotor portion 100, the stator portion 200, and the central shaft 300, the rotor portion 100 and the stator portion 200 are arranged on the central shaft 300, and one stator portion 200 is set in both sides of the rotor portion 100; the rotor portion 100 includes a rotor plate 110, The magnet array 120 and the blade array 130, the magnet array 120 is disposed on the rotor plate 110, and the two axial ends of the rotor plate 110 are fixedly coupled to a blade array 130, and the rotor plate 110 is provided with a first through hole, and the central axis 300 passes through the first A through hole and is fixed to the rotor plate 110, the blade array 130 is provided with a first dielectric film; the stator portio...

Embodiment 2

[0090] See Figure 6 to 7 , Image 6 A friction-electromagnetic composite power generation device performance test platform provided by the embodiment of the present invention.

[0091] A friction-electromagnetic composite power generation device provided by the present invention, including:

[0092] The fixing assembly 600, the regulator motor 700, and the electrostatic meter 800; the fixing assembly 600 includes a base 610, a platform 620, and a support rod 630, and one end of the base 610 opens an electric machine accommodating groove 611, and the other end is fixedly connected to the platform 620. 630 is disposed at one end of the base 610 and the support rod 630 is fixed to the platform 620, and the other end is fixed to the friction-electromagnetic composite power generation device in the first embodiment; the electrostatic meter 800 and the friction-electromagnetic composite power generation device output Non-electrical connection; the speed control motor 700 is fixed within ...

Embodiment 3

[0098] See Figure 8 to 13 , Figure 8 A performance test method for a friction-electromagnetic composite type generating device according to an embodiment of the present invention.

[0099] A friction-electromagnetic composite type generating device, including:

[0100] 10: Turn the radius of the electromagnetic composite power generation device by the speed control motor; 20: The electrical physical quantity corresponding to the rotational speed is obtained by the electrostatic meter, the electrical physical quantity includes voltage, current, and electricity: 30: Calculate the performance index value according to the electrical physical quantity The performance indicators include cycle average output power, power density, frictional surface charge density or material quality factor.

[0101] Specifically,: 1) Secure the friction-electromagnetic composite power generation device to the performance test platform of the friction-electromagnetic composite power generation device prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com