Shell stator assembly of flat wire motor and assembling method thereof

A shell stator and assembly technology, which is applied in the field of shell stator assembly and its assembly, can solve problems such as stress and insulation failure, and achieve the effects of reducing axial length, improving NVH, and enhancing insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

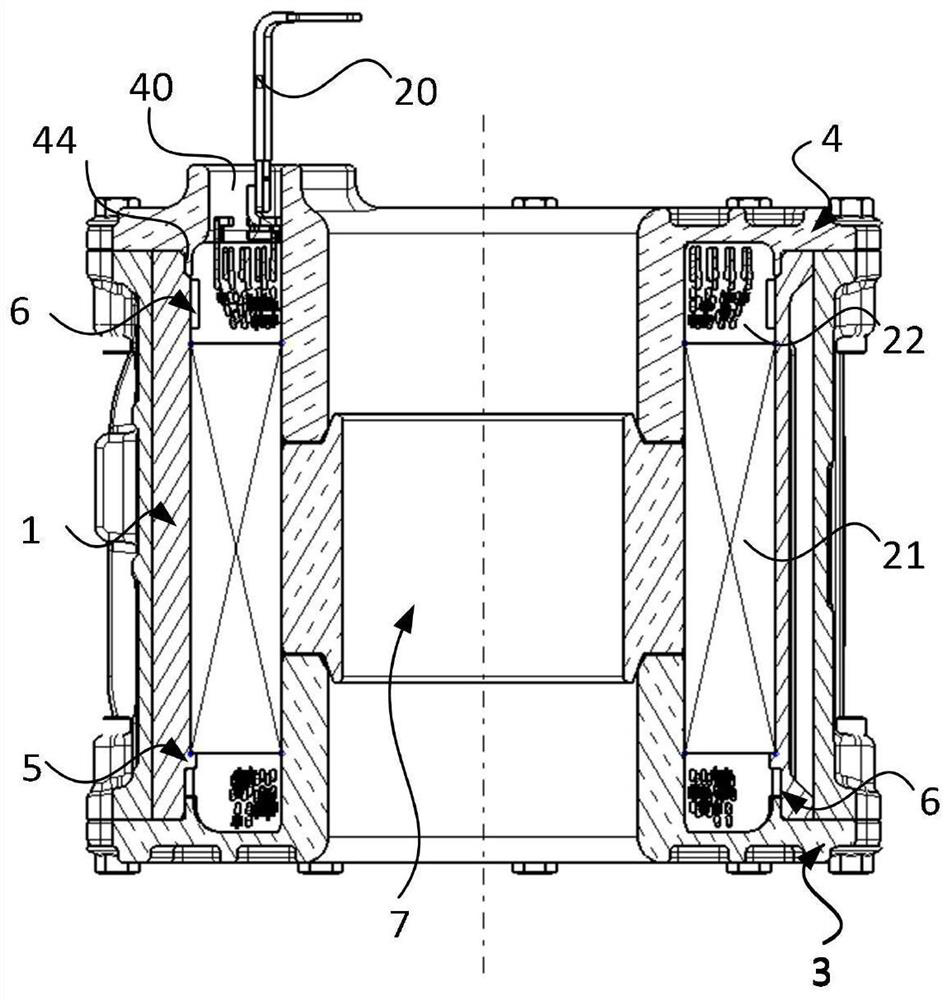

[0047] see Figure 1-3 As shown, Embodiment 1 of the present application provides a shell stator assembly of a flat wire motor, which includes a housing 1, a stator assembly 2, a lower cover 3 and an upper cover 4, and the stator assembly 2 is accommodated in the housing 1 , and there is a gap between the casing 1; the lower cover 3 is sealed at the bottom of the casing 1; the upper cover 4 is covered at the top of the casing 1, and the upper cover 4 is provided with a gap communicating with the The injection port 40 , and the lead wire 20 of the stator assembly 2 extends out of the injection port 40 .

[0048] When assembling, the stator assembly 2 is first shrunk into the housing 1 through interference fit; after cooling, a gap will be formed between the stator assembly 2 and the housing 1 due to shrinkage; then the lower cover 3 and the upper cover 4 are sealed separately. Cover the bottom and top of the housing 1, and form an airtight structure with the housing 1; finally...

Embodiment 2

[0074] Embodiment 2 of the present application provides an assembly method of a shell stator assembly of a flat wire motor, which includes the following steps:

[0075] S1: Put the stator assembly 2 into the casing 1 through interference fit and shrink fit, the stator assembly 2 includes an iron core 21, and flat copper wires 22 separately arranged at both ends of the iron core 21;

[0076] S2: After cooling, a gap is formed between the stator assembly 2 and the housing 1, and a thermally conductive adhesive strip 6 is pasted between the housing 1 and the two flat copper wires 22;

[0077] S3: Cover the lower cover 3 and the upper cover 4 on the bottom end and the top end of the casing 1 respectively;

[0078] S4: inject potting compound into the glue injection port 40, so that the potting compound fills the gap.

[0079] After the potting glue is solidified, the stator assembly 2 and the casing 1 are bonded by the potting glue, which increases the strength of the entire casi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com