Equipment and process for automatically packaging secondary lead of miniature current transformer for instrument

A technology for current transformers and secondary leads, which is applied in the field of automatic packaging secondary lead equipment and technology for miniature current transformers for instruments, can solve the problems of high proficiency requirements for employees and low production efficiency, so as to improve production efficiency and reduce Carbon emissions and the effect of reducing production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

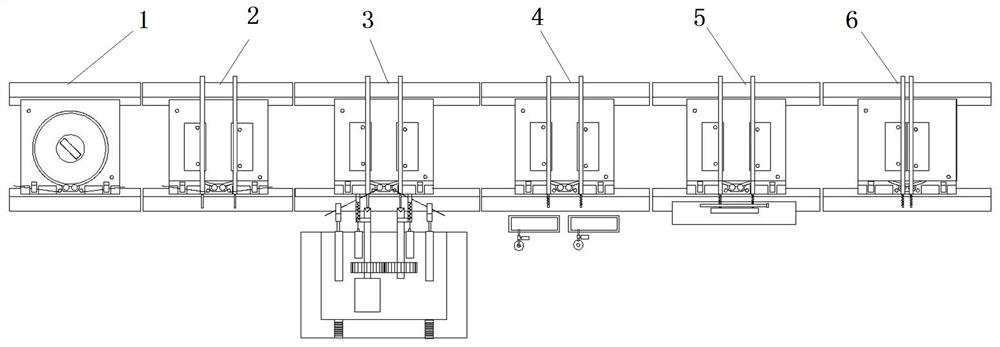

[0034] Example: such as figure 1 As shown in the figure, a device for automatically encapsulating the secondary leads of miniature current transformers for instruments includes a special tooling for placing and processing each miniature current transformer, an assembly line, and a feeding module 1, an on-line module 2, and an assembly line arranged sequentially on the assembly line. Winding module 3, welding module 4, thread cutting module 5, wire insertion module 6 stations, and there is a tooling return channel under the assembly line;

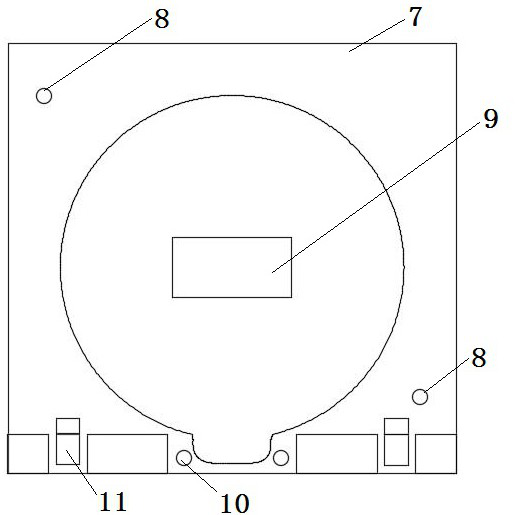

[0035] Such as Figure 2-Figure 5 As shown, the tooling includes a base 7 and an upper cover 13, the base is provided with a placement groove for placing the micro current transformer 12 to be processed, the bottom of the base is provided with a magnetic steel, and the two sides of the base are respectively provided with a positioning pin 8, a guide column 10 and Felt clips 11, the upper cover is provided with positioning holes 15 correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com