Fault severity evaluation method based on variable-step multi-scale complexity fusion index

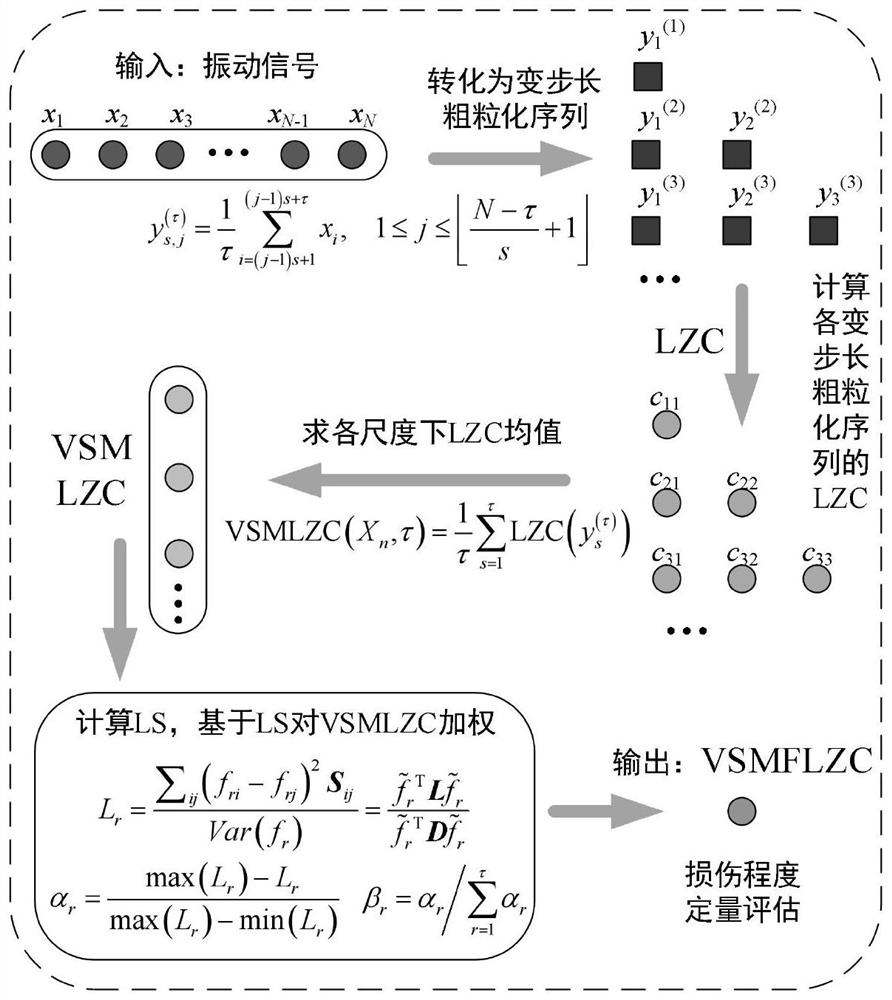

A technology of severity and complexity, which is applied in the field of fault severity assessment of variable-step multi-scale complexity fusion indicators, and can solve problems such as incomplete fault feature extraction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

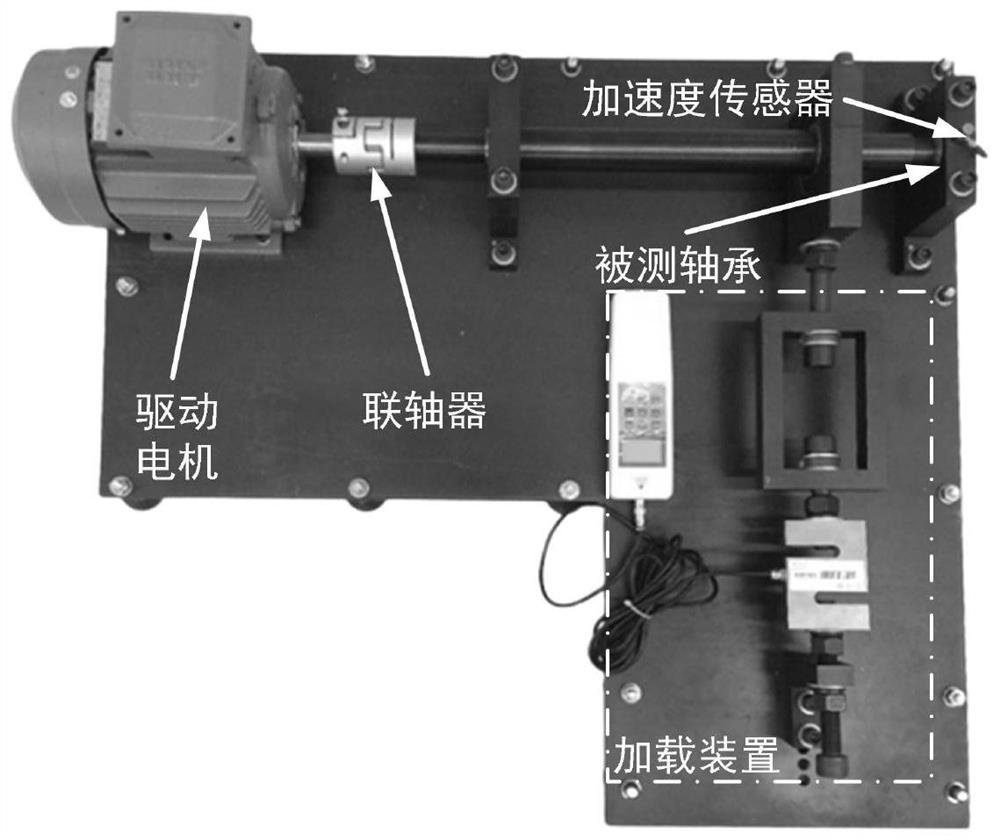

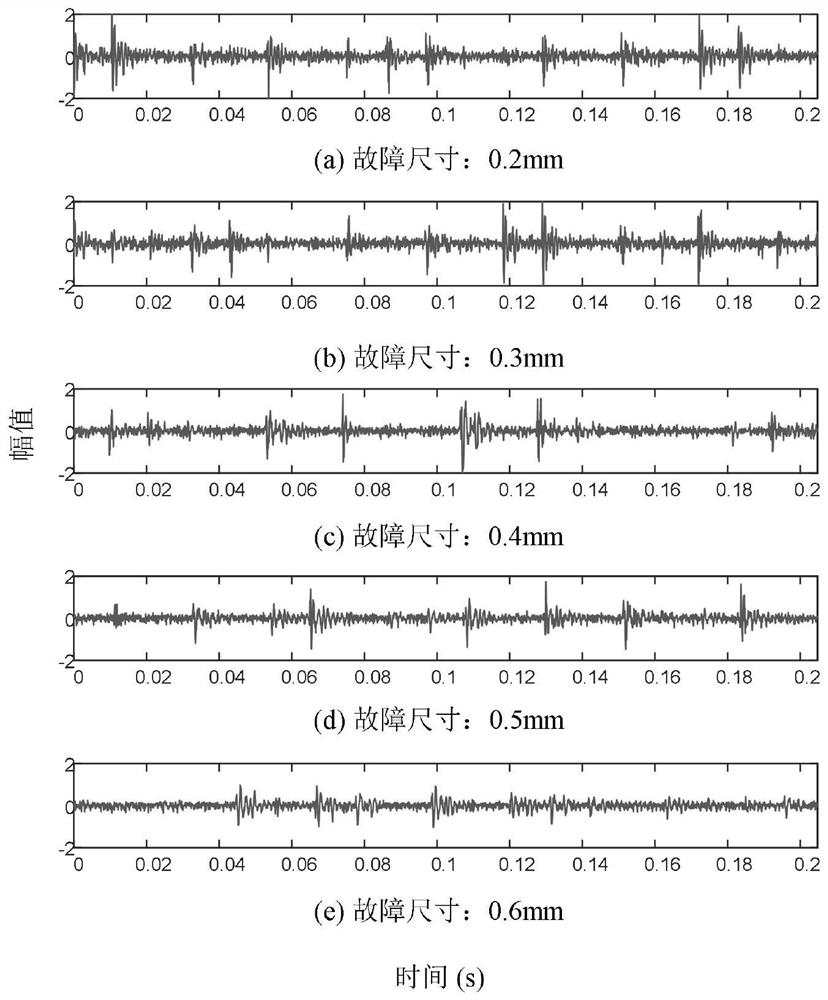

[0050] The experimental data comes from the bearing fault simulation test bench with visual radial loading. The test device is as follows: figure 1 shown. The tested bearing adopts 6205-2RSSKF deep groove ball bearing, and the inner ring, outer ring and rolling body of the bearing are respectively processed with a width of about 0.2mm, 0.3mm, 0.4mm, 0.5mm, 0.6mm and a depth of about 0.3mm by wire cutting method. groove. The bearing is driven by a drive motor at a speed of 900r / min, and the sampling frequency is set at 10kHz. figure 1 The acceleration sensor in the test is installed above the bearing under test, and the loading device can realize radial loading on the bearing, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com