High-strength and high-toughness thick-wall nodular cast iron material and casting method thereof

A high-strength, toughness, squash technology, applied in the field of cast iron materials, can solve the problems of high production cost, high price, complicated process, etc., and achieve the effects of low production cost, increased content, and prevention of inoculation and recession.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

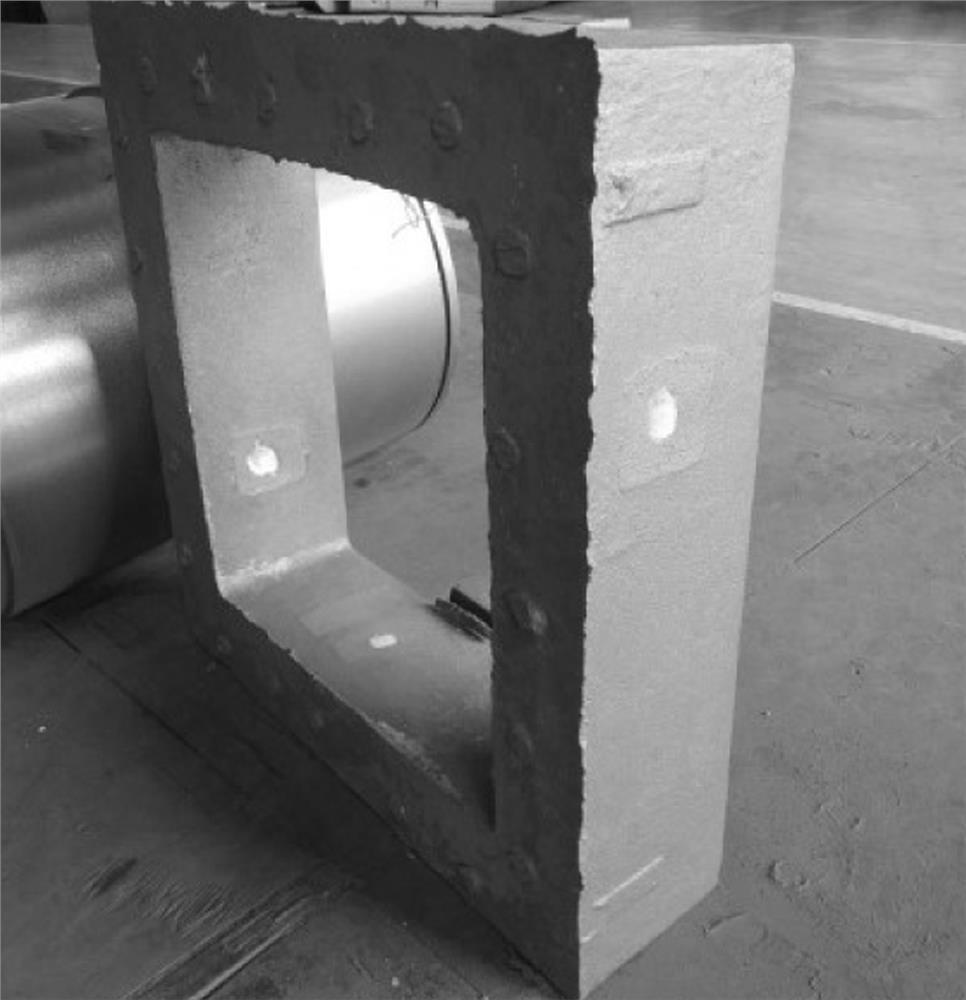

[0027] 1. Modeling: the selection of trial-produced parts figure 1 For round-shaped frame castings, the pouring weight is about 2000kg, and the wall thickness is 160mm. For each casting, three 140mm thick test blocks are placed.

[0028] 2. Smelting: The furnace charge is specifically: 1000kg high-purity pig iron, 1000kg scrap steel, 40kg recarburizer and 20kg ferrochrome; among them, high-purity pig iron is bread pig iron with Fe content accounting for more than 95%, of which C 4.0-4.2%, Si0. 30-0.40% and the rest are Mn, P, S and other unavoidable trace impurity alloy elements; steel scrap is ordinary carbon steel with Mn content ≤0.7%, carburizer nitrogen content ≤0.03%, carbon content ≥97%; Cr Iron is a ferrochrome alloy with a Cr content of 50-55%.

[0029] A medium frequency induction furnace is used to melt the ingredients into molten iron. When the temperature of the molten iron reaches 1410±5°C, samples are taken for spectral analysis, and the chemical composition of...

Embodiment 2

[0038] 1. Modeling: the selection of trial-produced parts figure 1 For round-shaped frame castings, the pouring weight is about 2000kg, and the wall thickness is 160mm. For each casting, three 140mm thick test blocks are placed.

[0039] 2. Smelting: The charge is specifically: 1000kg high-purity pig iron, 1000kg scrap steel, 40kg recarburizer and 17kg ferrochrome.

[0040] A medium-frequency induction furnace is used to melt the ingredients into molten iron. When the temperature of the molten iron reaches 1407°C, samples are taken for spectral analysis. According to the analysis results, the chemical composition of the molten iron in the furnace is adjusted to meet the specified requirements. The composition control in the furnace is: C3.55%; Si 0.32%; Mn0.35%; P0.02%; S0.01%; Cr 0.42. After the composition is qualified, the molten iron continues to heat up to 1503°C, heats it for 4 minutes, and then cools down to 1444°C to release the molten iron.

[0041] Prepare a 3T pou...

Embodiment 3

[0049] 1. Modeling: the selection of trial-produced parts figure 1 For round-shaped frame castings, the pouring weight is about 2000kg, and the wall thickness is 160mm. For each casting, three 140mm thick test blocks are placed.

[0050] 2. Smelting: The charge is specifically: 1000kg high-purity pig iron, 1000kg scrap steel, 40kg recarburizer and 27kg ferrochrome.

[0051] A medium-frequency induction furnace is used to melt the ingredients into molten iron. When the temperature of the molten iron reaches 1414°C, samples are taken for spectral analysis. According to the analysis results, the chemical composition of the molten iron in the furnace is adjusted to meet the specified requirements. The composition control in the furnace is: C3.78%; Si 0.59%; Mn0.49%; P0.058%; S0.049%; Cr 0.67. After the composition is qualified, the molten iron continues to heat up to 1508°C, heats it for 7 minutes, and then cools down to 1449°C to release the molten iron.

[0052] Prepare a 3T p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com