Numerical control plate shearing and blanking machine

A technology of blanking machine and shearing plate, which is applied in the direction of shearing equipment, shearing devices, and attachments of shearing machines. The overall cleanliness and other issues can be achieved to reduce the probability of wrinkles and tilts, reduce the probability of tilting and shaking, and improve the level of flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

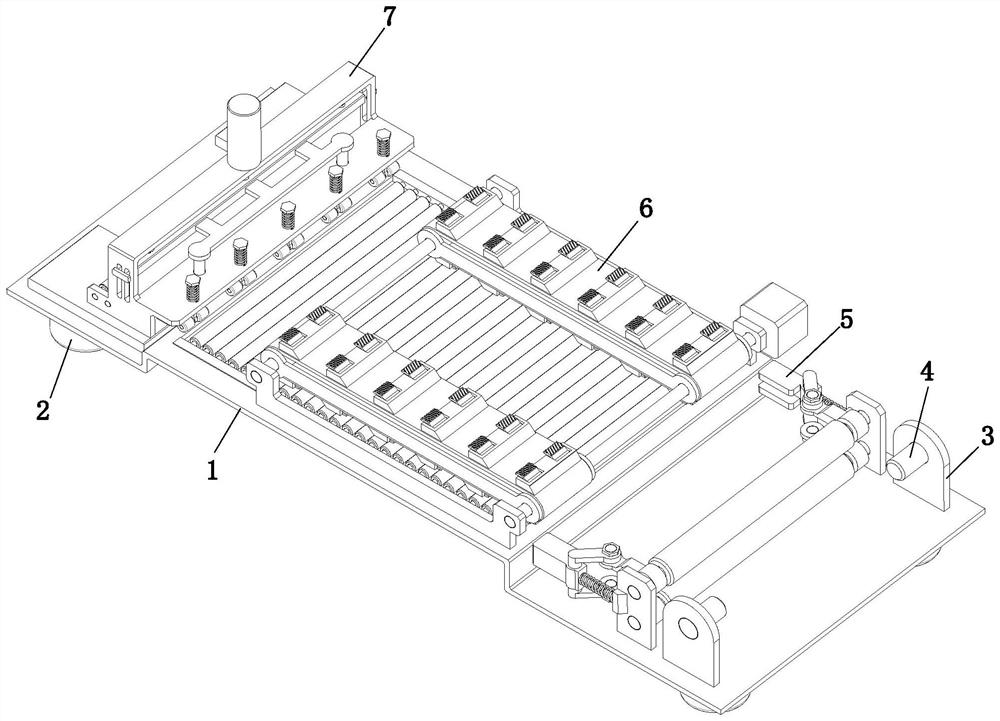

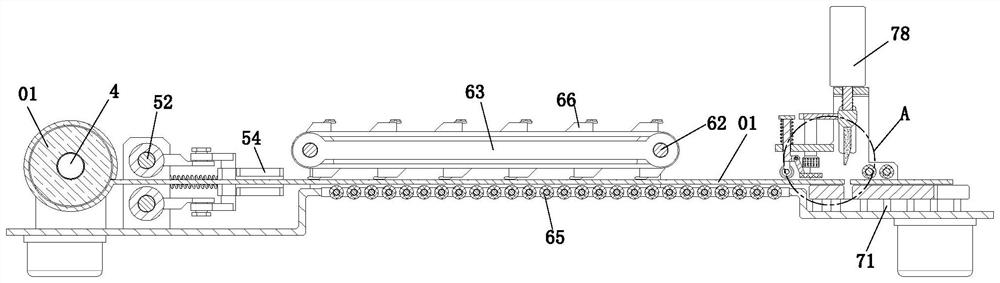

[0030] refer to figure 1 and figure 2 , a numerically controlled shearing board blanking machine, comprising a mounting frame 1, a supporting foot 2, a placement plate 3, a placement shaft 4, a leveling mechanism 5, a conveying mechanism 6 and a shearing plate mechanism 7, the corners around the lower end of the mounting frame 1 Both support feet 2 are installed, and the upper front side of the mounting frame 1 is symmetrically installed with a placement plate 3, the upper end of the placement plate 3 is equipped with a placement shaft 4 through a bearing, and a leveling mechanism 5 is installed on the upper front side of the mounting frame 1. The middle part of the upper end of 1 is equipped with conveying mechanism 6, and the upper end rear side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com