Method for relieving anode poisoning of proton exchange membrane fuel cell by utilizing transient temperature rise

A proton exchange membrane and fuel cell technology, applied in fuel cells, circuits, electrical components, etc., can solve problems such as poor operability, complicated operation, and no anode catalyst found, and achieve improved operation stability with a simple and easy method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

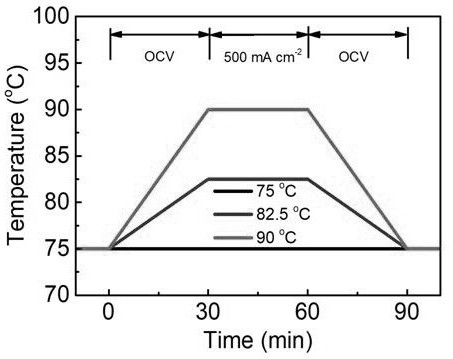

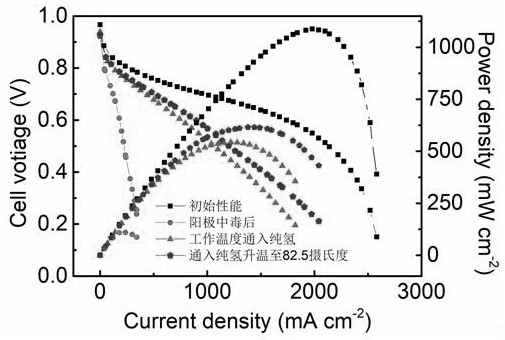

Embodiment 1

[0027] After the fuel cell is poisoned by the anode catalyst, the anode side is fed with a gas flow of 200 sccm high-purity hydrogen, and the cathode side is fed with a gas flow of 800 sccm air, and the fuel cell is at the open circuit potential. Increase the operating temperature of the fuel cell at a rate of 1 degree Celsius per minute, set the temperature to 82.5 degrees Celsius, and run the fuel cell at this temperature for 1 hour, and the battery is 500mA cm -2 Constant current operation. After the operation is completed, reduce the operating temperature of the fuel cell and set the temperature to the normal operating temperature of the fuel cell. During the cooling process, the fuel cell is at the open circuit potential, and then perform an activation test on the fuel cell. The mitigation methods are as follows: figure 1 shown. vs. 1000 mA cm -2 The battery performance under the current density, it can be seen that the method of introducing high-purity hydrogen at the ...

Embodiment 2

[0029] Using the same test method as in Example 1, the operating temperature of the fuel cell was changed, and the temperature was set to 90 degrees Celsius. The study found that, consistent with the results of Example 1, compared with the performance recovery ratio of the pure hydrogen battery, the battery performance recovery under the 90°C operation mitigation strategy also increased significantly, reaching 86.6%. Due to the increase in temperature, the desorption of impurities It is easier and the recovery rate is also significantly increased.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com