Emergency order-oriented resource scheduling collaborative optimization method for flexible job shop

A collaborative optimization and resource scheduling technology, applied in the direction of resources, data processing applications, instruments, etc., can solve problems such as failure to meet production requirements, sequential constraints on processes, and no practical guiding significance to improve computing speed and robustness. Improve the efficiency of solving and expand the effect of sampling space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

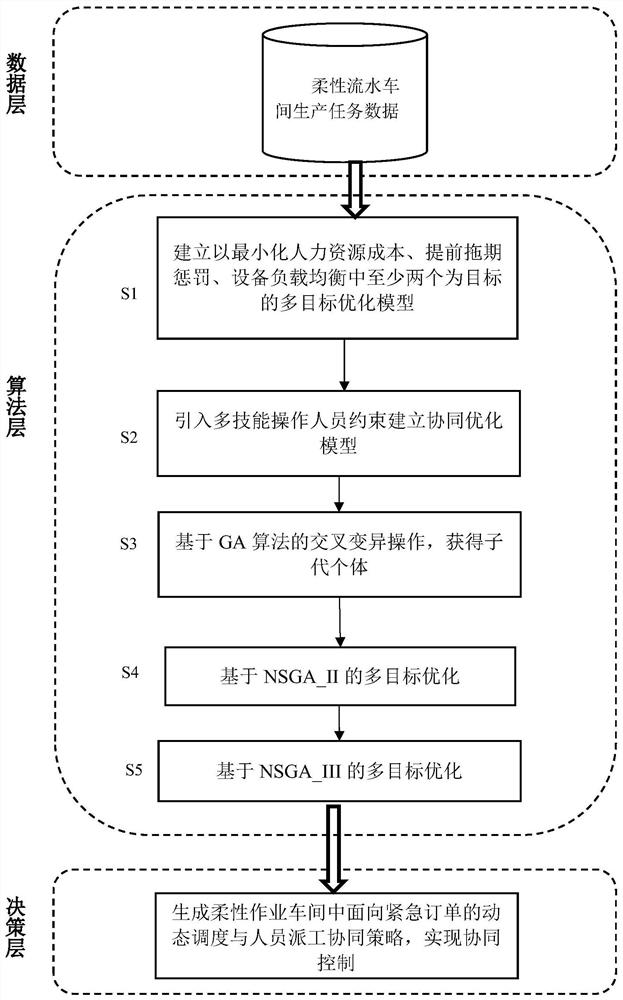

[0042] This embodiment provides a resource scheduling collaborative optimization method for urgent orders in a flexible job shop. The resources include workpieces and personnel, and are used to realize the collaborative control of workpiece scheduling and personnel dispatching. Such as figure 1As shown, the method is implemented based on the data layer, algorithm layer and decision-making layer, wherein the data layer includes the production task data of the flexible flow shop, the algorithm layer performs resource scheduling collaborative optimization based on the data of the data layer, and the decision-making layer performs collaborative optimization based on the collaborative optimization results. Collaborative control of workpiece scheduling and personnel dispatching. The collaborative optimization process of resource scheduling at the algorithm layer includes the following steps:

[0043] Step S1: Determine all objective functions and production constraints of dynamic s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com