Yarn breakage early warning monitoring method, system, device and readable storage medium

A technology of early warning monitoring and yarn, which is applied in the field of textile processing, can solve the problems of affecting production efficiency, spending a lot of time, and not being able to warn in advance, so as to improve work efficiency, improve accuracy, and reduce thread breakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

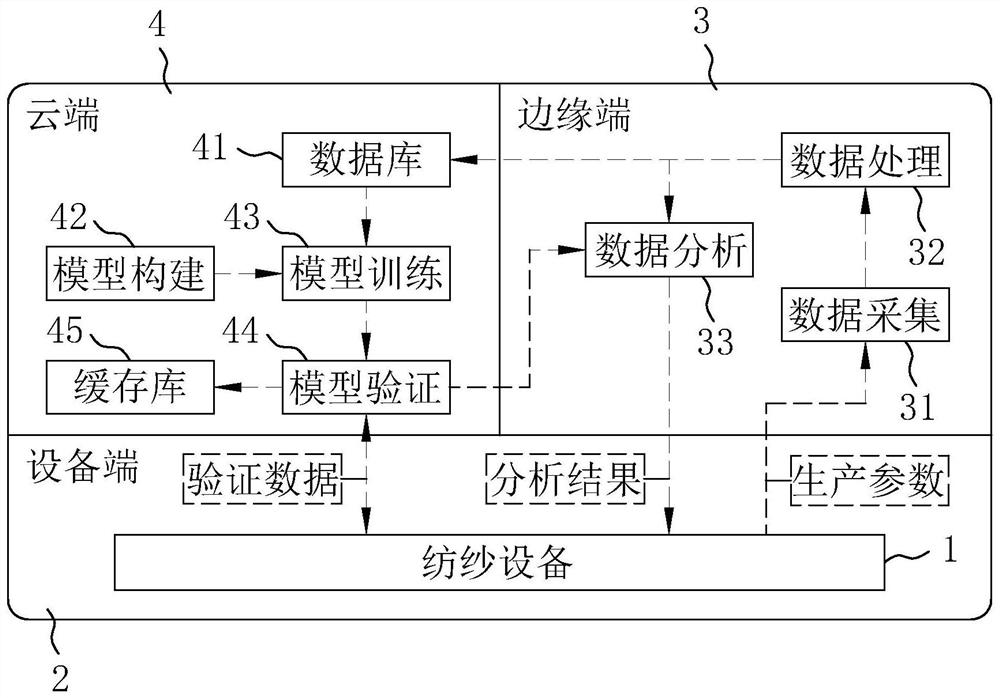

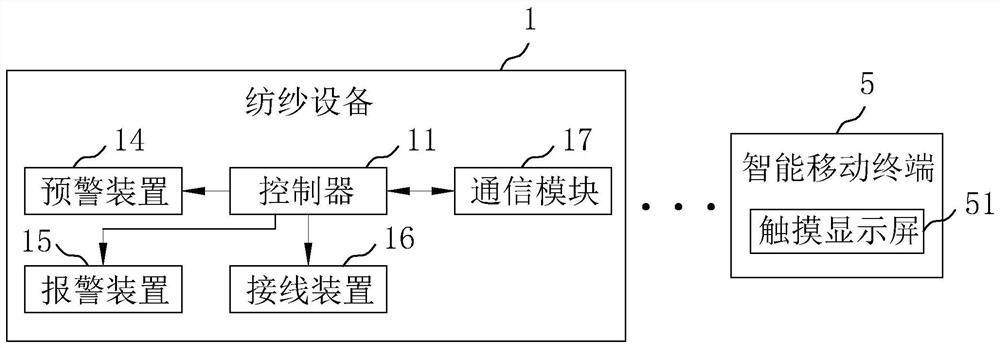

[0068] refer to figure 1 , is a yarn breakage early warning monitoring system disclosed in the present invention, including a device end 2, an edge end 3 and a cloud 4. The equipment end 2 is used for yarn production and detection of various types of production parameters in the production process. Wherein, various types of production parameters include but are not limited to yarn breakage confirmation information, yarn thickness data, and yarn pressure data on the wire feeding roller.

[0069] refer to figure 1 and figure 2 , the edge terminal 3 is used to obtain various types of production parameters collected by the equipment terminal 2, and at the same time obtain the result data according to the preset mathematical model and the obtained production parameters, and feed back the result data to the spinning of the equipment terminal 2 The controller 11 of the device 1 . The result data obtained by the edge terminal 3 includes but not limited to parameter normal command...

Embodiment 2

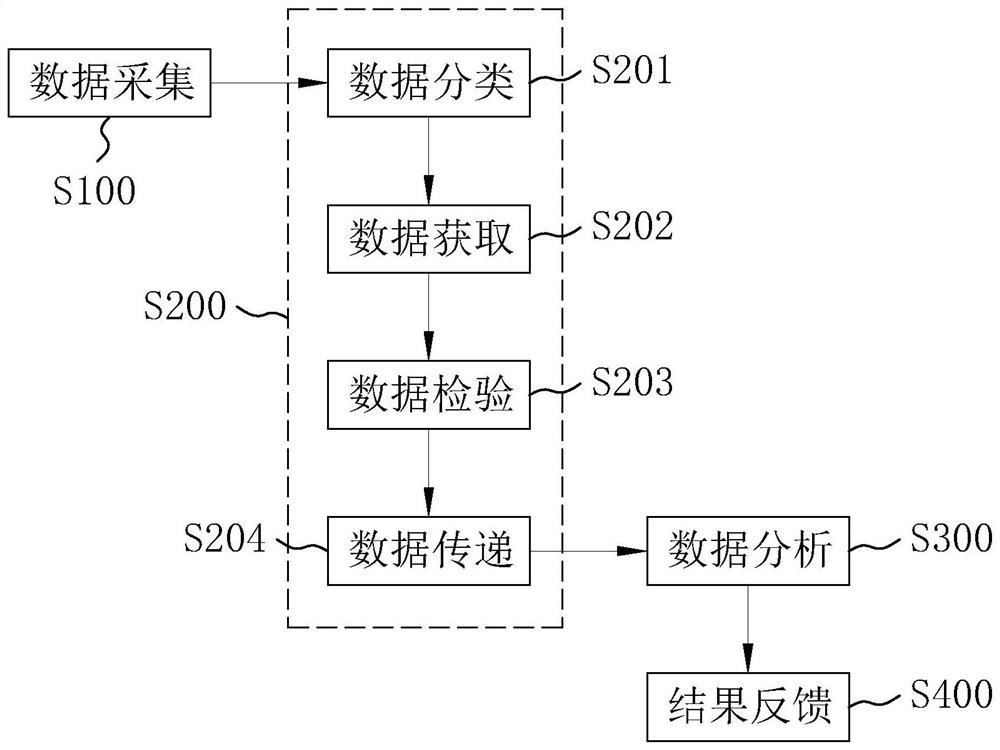

[0079] Based on the yarn breakage early warning monitoring system in Embodiment 1, this embodiment provides a yarn breakage early warning monitoring method, referring to figure 2 and image 3 , which includes the following steps:

[0080] S100. Data collection: Acquire various types of production data of the spinning device 1, the various types of production data include but not limited to the thread break confirmation information when the yarn breaks, the thickness data of the yarn, and the impact of the wire feeding roller. yarn pressure data.

[0081] S200. Data processing: process and classify the production data obtained in step S100 according to a general mathematical processing method, and judge the rationality of the processed and classified data according to a preset judgment engine.

[0082] S300. Data analysis: classify and judge the data judged to be reasonable in step S200 according to a preset mathematical model, and obtain result data.

[0083] S400, result ...

Embodiment 3

[0093] A yarn breakage early warning and monitoring device includes a memory and a processor, and the memory stores a computer program that can be loaded by the processor and execute the yarn breakage early warning and monitoring method in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com