Multi-objective optimization design method of spiral oil wedge bearing

A technology of multi-objective optimization and design method, which is applied in the field of multi-objective optimization design of spiral oil wedge bearings, and can solve the problems of insufficient global optimization ability and insufficient calculation accuracy of spiral oil wedge bearing optimization design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

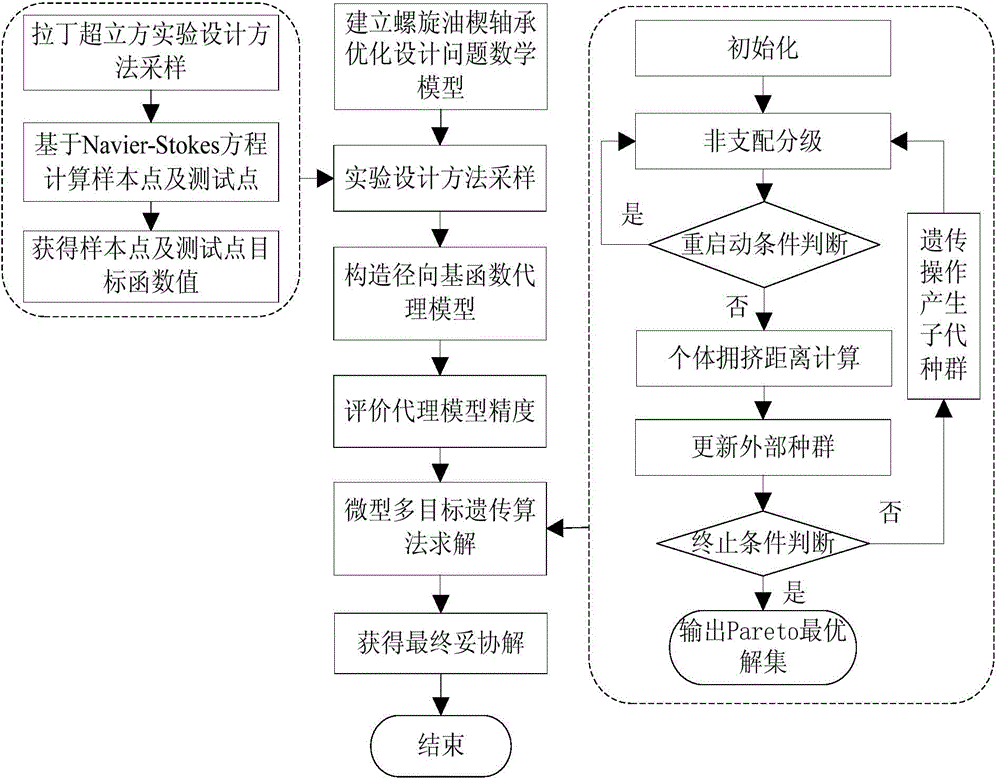

[0035] A multi-objective optimization design method for spiral oil wedge bearings, the calculation process of this method is as follows figure 1 As shown, the specific steps are as follows:

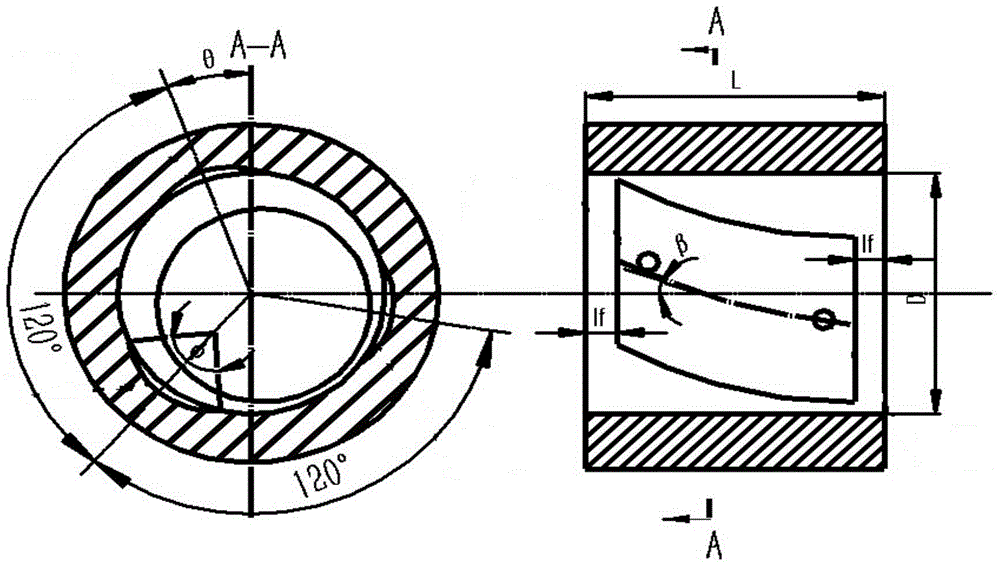

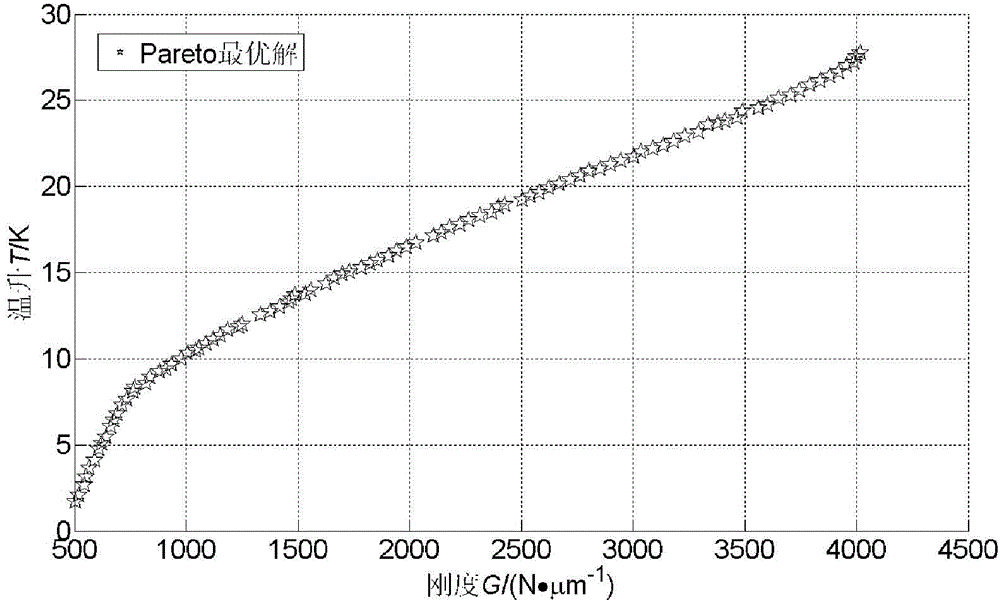

[0036] Step 1: Build as figure 2 The mathematical model of the multi-objective optimization design problem of the spiral oil wedge bearing structure shown, the optimal design variable selects the bearing radius clearance x 1 , length of sealing edge x 2 , helix angle x 3 , oil chamber wrap angle x 4 , oil chamber depth x 5 , because in the design of hydrodynamic and static pressure bearings, it is generally hoped that the oil film stiffness should be high, and at the same time, the temperature rise should be as small as possible, but these two performance indicators are contradictory, so the optimal desig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com